Preparation method of high-performance silicon carbon-graphite negative material

A graphite anode, high-performance technology, used in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve the problems of high expansion rate, poor cycle performance and rate performance, and reduce expansion, discharge The effect of stable voltage and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

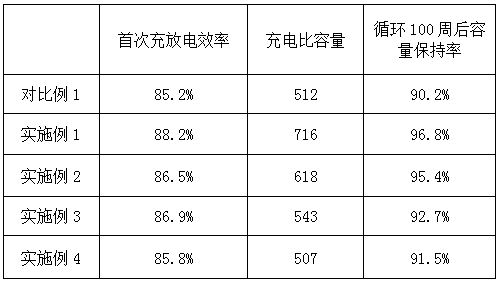

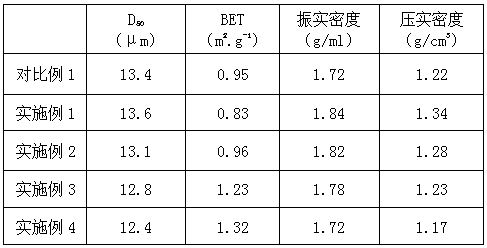

Examples

Embodiment 1

[0028] ① Disperse silicon powder with a particle size of 5 μm and butyl titanate (1% butyl titanate mass fraction) in ethanol to prepare a slurry with a solid content of 30%, and pulverize it in a ball mill for 5 hours to obtain granules Nano-slurry with a diameter of 100nm; ② Disperse the nano-slurry and PVDF (the mass percentage of PVDF is 2%) in ethanol to prepare a suspension A with a solid content of 30%, and use a vacuum dryer with a condensing system in the Vacuum-dry the suspension A at a temperature of 90°C, and the vacuum negative pressure does not exceed 0.1Mpa to obtain a silicon-carbon precursor; ③ Add graphite, polymer compound, and silicon-carbon precursor to the Carry out carbonization treatment in an electric heating high-speed modification mixer, raise the temperature to 600°C under nitrogen protection, the heating rate is 1°C / min, keep it warm for 6 hours, then cool to room temperature, and sieve out the material with a median particle size of 5 μm , to obta...

Embodiment 2

[0030] ① Disperse silicon powder with a particle size of 10 μm and ethyl titanate (the mass fraction of ethyl titanate is 3%) in glycerol, prepare a slurry with a solid content of 20%, and pulverize it in a ball mill for 20 hours. Obtain a nano-slurry with a particle size of 108nm; ② disperse the nano-slurry and polyurethane (the mass percentage of polyurethane is 4%) in glycerol, and prepare a suspension with a solid content of 25%. Liquid A is vacuum-dried at an inlet temperature of 250°C and an outlet temperature of 110°C to obtain a silicon-carbon precursor; ③ Add graphite, polymer compounds, and the obtained silicon-carbon precursor to electric heating at a mass ratio of 45:1:4 Carry out carbonization treatment in a type high-speed modified mixer, heat up to 700°C under nitrogen protection, the heating rate is 5°C / min, keep warm for 3 hours, then cool to room temperature, sieve out the material with a median particle size of 13μm, and obtain The silicon-carbon composite n...

Embodiment 3

[0032]Disperse silicon powder with a particle size of 4 μm and titanium isopropoxide (the mass fraction of titanium isopropoxide is 5%) in ethanol, prepare a slurry with a solid content of 10%, and pulverize it in a ball mill for 15 hours to obtain the particle size 145nm nano-slurry; ② Disperse the nano-slurry and polyvinyl chloride resin (the mass percentage of polyvinyl chloride resin is 7%) in ethanol to prepare a suspension A with a solid content of 25%. Vacuum drying under the conditions to obtain the silicon carbon precursor; ③ According to the mass ratio of 87:2:11, graphite, polymer compound and the obtained silicon carbon precursor were added to the electric heating type high-speed modification mixer for carbonization treatment, and the Under protection, the temperature was raised to 900°C at a heating rate of 10°C / min, kept for 4 hours, then cooled to room temperature, and the material with a median particle size of 30 μm was screened out to obtain the silicon-carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com