Super-abrasion-resistant anti-fouling UV-cured coating and preparation method and application thereof

A curing coating, super wear-resistant technology, used in antifouling/underwater coatings, epoxy coatings, polyurea/polyurethane coatings, etc. Abrasion, scratch resistance, vulnerable to wear, insufficient surface protection, etc., to achieve good stain resistance, longevity, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

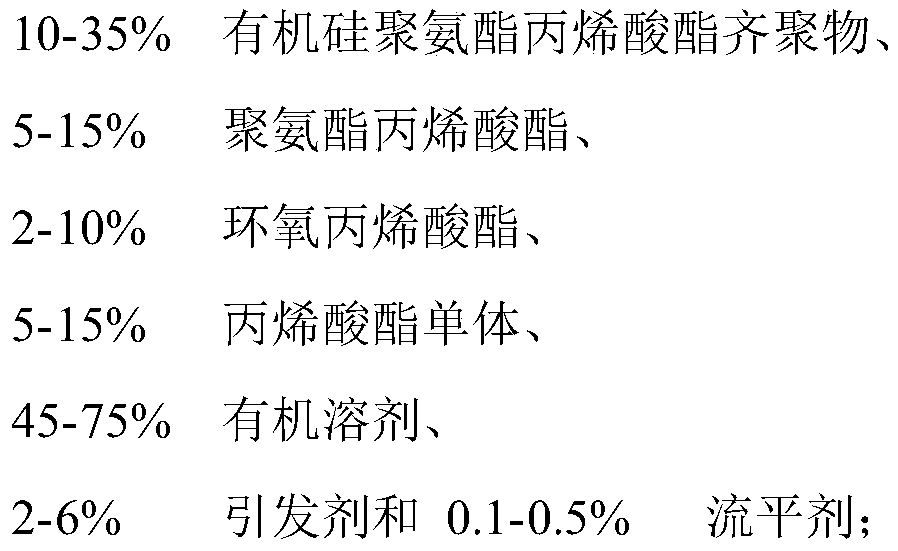

[0044] A kind of super wear-resistant and antifouling UV curing paint of the present invention, comprises A component transparent varnish and B component wear-resistant matte slurry; A component transparent varnish is mainly prepared from the raw material of following weight content:

[0045]

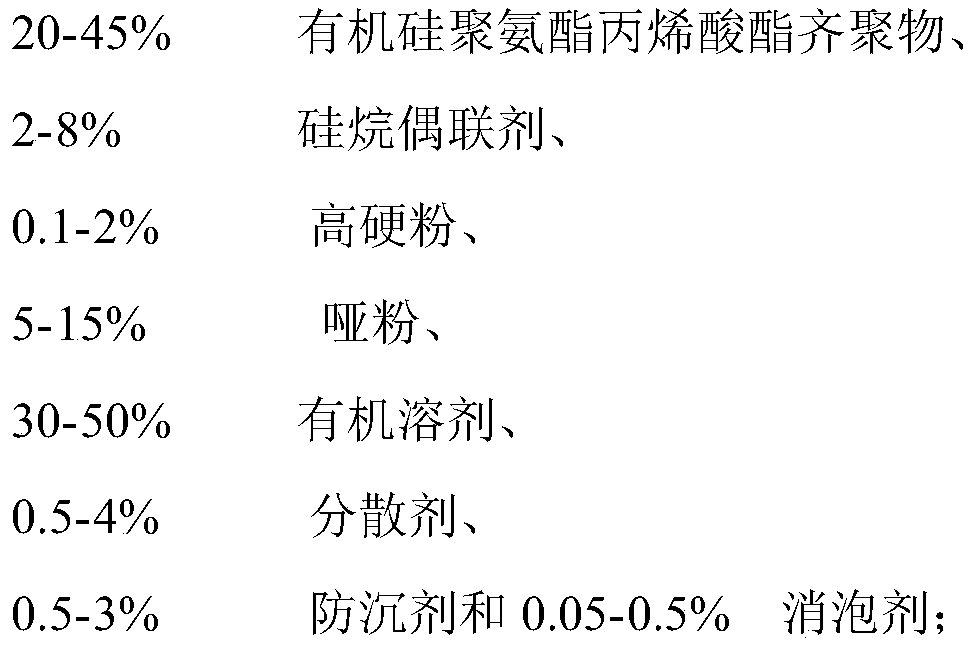

[0046] B component wear-resistant matting pulp is mainly prepared from the following raw materials by weight:

[0047]

[0048] Among them, the silicone urethane acrylate oligomer is obtained by reacting hydroxyl polysiloxane with a molecular weight of 1500 and isophorone diisocyanate to obtain a silicone prepolymer, and then reacting the silicone prepolymer with pentaerythritol triacrylate monomer Prepared; polyurethane acrylate is a bifunctional polyurethane acrylate prepared from 2000 molecular weight polycaprolactone diol, isophorone diisocyanate and hydroxyethyl acrylate monomer.

[0049] The preparation process of the super wear-resistant antifouling UV curing coating of the...

Embodiment 2

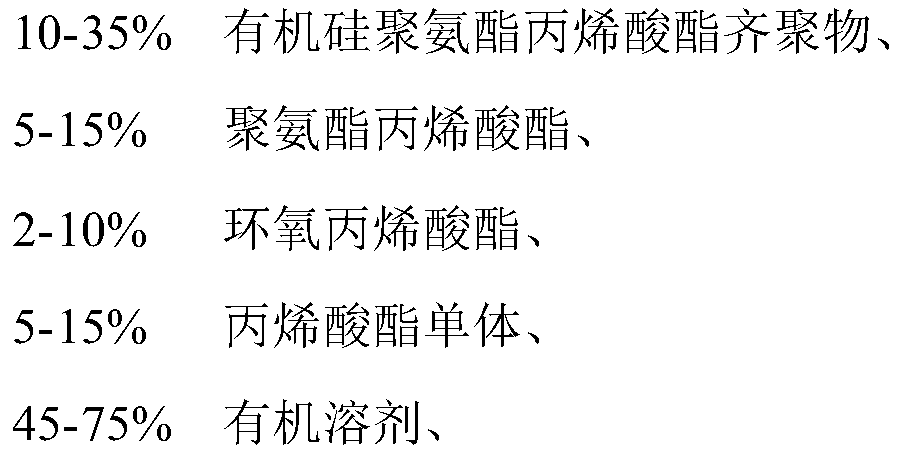

[0057] A kind of super wear-resistant and antifouling UV curing paint of the present invention, comprises A component transparent varnish and B component wear-resistant matte slurry; A component transparent varnish is mainly prepared from the raw material of following weight content:

[0058]

[0059] B component wear-resistant matting pulp is mainly prepared from the following raw materials by weight:

[0060]

[0061]

[0062] Among them, the silicone urethane acrylate oligomer is obtained by reacting hydroxyl polysiloxane with a molecular weight of 2500 and 4,4'-dicyclohexylmethane diisocyanate to obtain a silicone prepolymer, and then combining the silicone prepolymer with pentaerythritol tris It is prepared by the reaction of acrylate monomers; polyurethane acrylate is a bifunctional polyurethane acrylate prepared from 1000 molecular weight polycaprolactone diol, isophorone diisocyanate and hydroxyethyl acrylate monomer.

[0063] The preparation process of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com