Magnetic Fe3O4@PS-TMT nanoparticle with adsorption function and preparation method thereof

A nanoparticle and magnetic technology, which is applied in the field of adsorption functional magnetic Fe3O4@PS-TMT nanoparticles and its preparation, can solve the problems of restricting the application of adsorption method, small adsorption capacity, slow adsorption rate, etc., and achieves reduced time and good uniformity. , the effect of promoting the uniformity of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

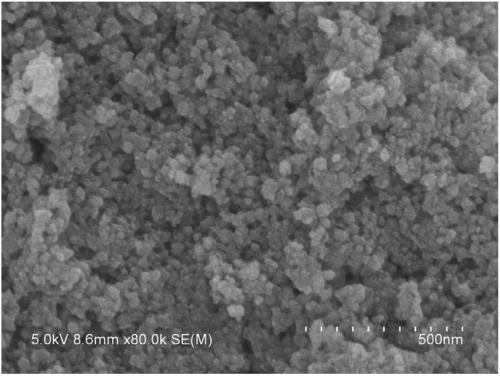

[0041] A kind of adsorption function magnetic Fe 3 o 4 The preparation method of @PS-TMT nanoparticles comprises the following steps:

[0042] S1. Weigh 2119.2 mg of iron acetylacetonate and add it to 20 mL of diphenyl ether, then add 1 mL of oleylamine, 1 mL of ethylene glycol, and 1 mL of oleic acid, stir evenly, and react for 0.5 h at 200°C in a nitrogen atmosphere. After refluxing at 250°C for 1 hour, stop heating, cool to room temperature, magnetically separate the black product, and wash once with acetone to obtain ferric oxide nanoparticles coated with oleic acid-oleylamine;

[0043] S2. Disperse the iron ferric oxide nanoparticles wrapped with oleic acid-oleylamine obtained in step S1 into 2mL of dichloromethane, and add 600mg of cetyltrimethylammonium bromide, 0.5ml of n-butanol and 36mL of distilled water, stirred and mixed evenly, ultrasonicated for 10min to form a fine emulsion, and then heated at 60°C for 10min to remove dichloromethane to prepare a magnetic fer...

Embodiment 2

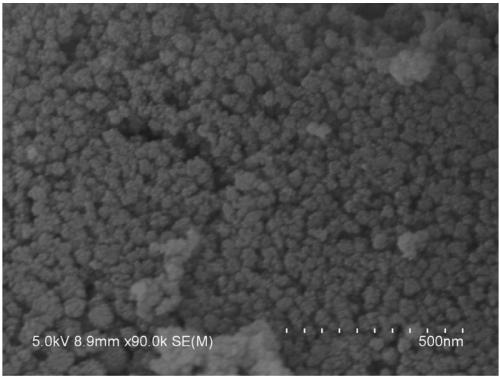

[0050] A kind of adsorption function magnetic Fe 3 o 4 The preparation method of @PS-TMT nanoparticles comprises the following steps:

[0051] S1. Weigh 2119.2 mg of iron acetylacetonate and add it to 20 mL of diphenyl ether, then add 1 mL of oleylamine, 1 mL of ethylene glycol, and 1 mL of oleic acid, stir evenly, and react for 0.5 h at 200°C in a nitrogen atmosphere. After refluxing at 250°C for 1 hour, stop heating, cool to room temperature, magnetically separate the black product, and wash once with acetone to obtain ferric oxide nanoparticles coated with oleic acid-oleylamine;

[0052] S2. Disperse the iron ferric oxide nanoparticles wrapped with oleic acid-oleylamine obtained in step S1 into 2mL of dichloromethane, and add 400mg of cetyltrimethylammonium bromide, 0.3ml of n-butanol and 30mL of distilled water, stirred and mixed evenly, ultrasonicated for 10min to form a fine emulsion, and then heated at 60°C for 10min to remove dichloromethane and prepare a magnetic fe...

Embodiment 3

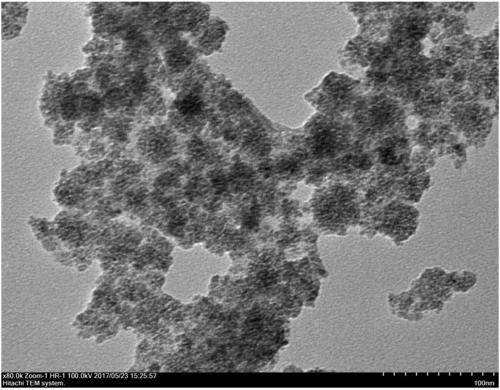

[0057] A kind of adsorption function magnetic Fe 3 o 4 The preparation method of @PS-TMT nanoparticles comprises the following steps:

[0058] S1. Weigh 2119.2 mg of iron acetylacetonate and add it to 20 mL of diphenyl ether, then add 1 mL of oleylamine, 1 mL of ethylene glycol, and 1 mL of oleic acid, stir evenly, and react for 0.5 h at 200°C in a nitrogen atmosphere. After refluxing at 250°C for 1 hour, stop heating, cool to room temperature, magnetically separate the black product, and wash once with acetone to obtain ferric oxide nanoparticles coated with oleic acid-oleylamine;

[0059] S2. Disperse the iron ferric oxide nanoparticles wrapped with oleic acid-oleylamine obtained in step S1 into 2mL of dichloromethane, and add 500mg of cetyltrimethylammonium bromide, 0.6ml of n-butanol and 42mL of distilled water, stirred and mixed evenly, ultrasonicated for 10min to form a fine emulsion, and then heated at 60°C for 10min to remove dichloromethane to prepare a magnetic fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com