1t-mos 2 Modified zncos solid solution hollow dodecahedron nanocomposite material and its preparation method and application

A nanocomposite material, 1t-mos2 technology, applied in chemical instruments and methods, hydrogen production, chemical/physical processes, etc., can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

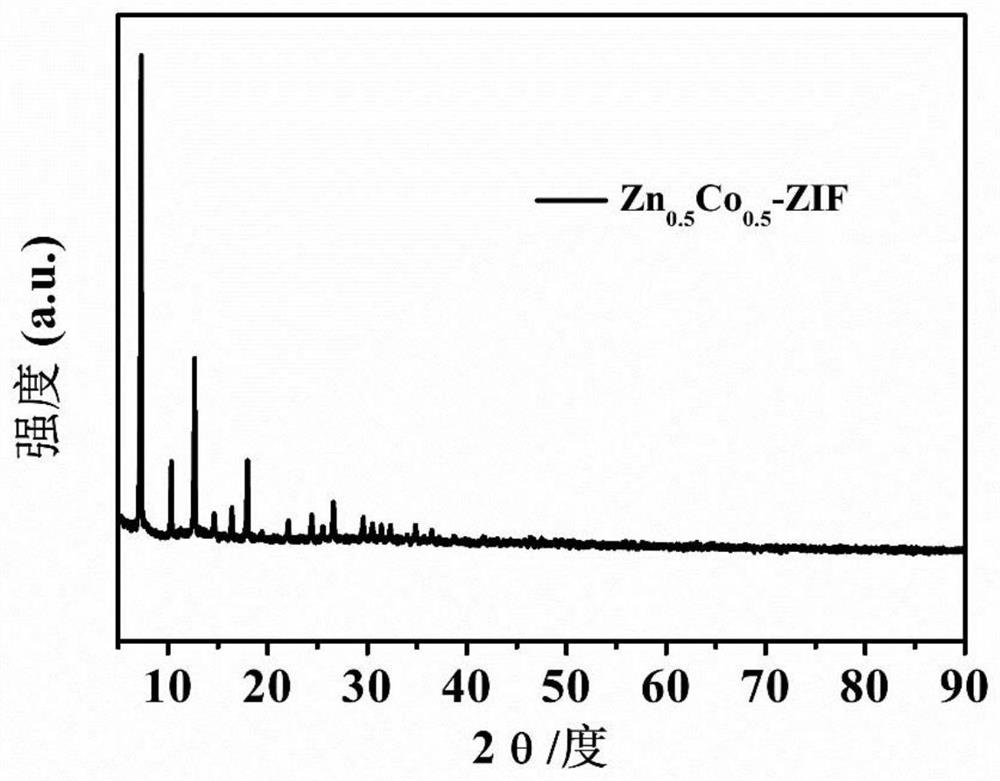

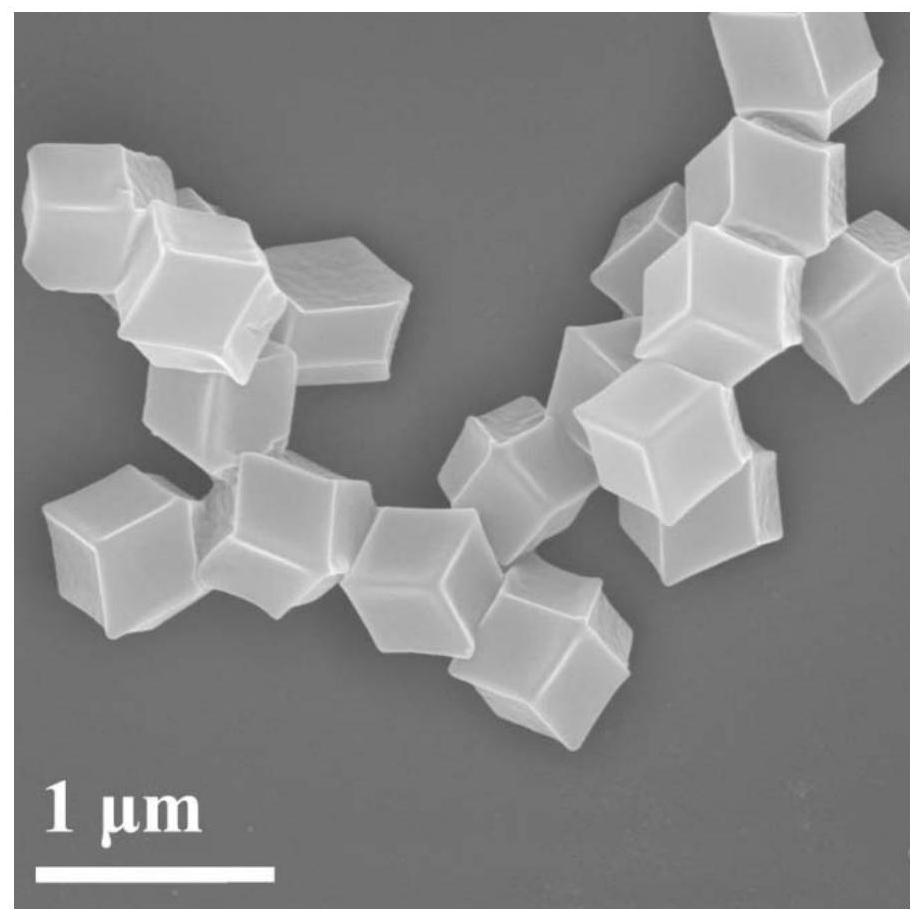

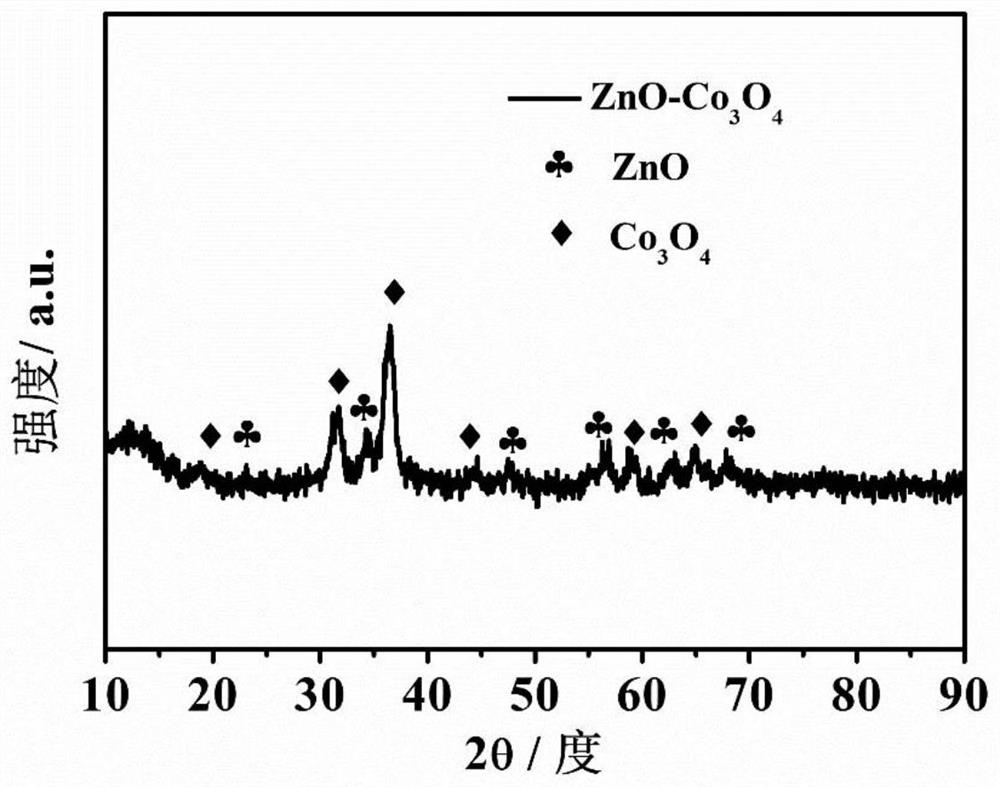

[0039] 1T-MoS 2 The preparation method of the modified ZnCoS solid solution hollow dodecahedral nanocomposite material, the specific steps are as follows:

[0040] (1) Preparation of metal organic framework material ZnCo-MOF:

[0041] Weigh 184mg of zinc acetate (1mmol) and 177mg of cobalt acetate (1mmol) and dissolve in 50ml of methanol solution, stir at room temperature until the solute is completely dissolved to obtain a mixed solution of the two metal salts, designated as solution A. Weigh 414 mg of dimethylimidazole (8 mmol) and dissolve it in 40 ml of methanol solution, and stir at room temperature until the solute is completely dissolved to obtain B solution. At room temperature, slowly add B solution into A solution, and keep stirring, keep stirring for 20 hours and then let it stand for 6 hours. The reaction product is separated by suction filtration, then washed with distilled water for 3 times and ethanol for 3 times, and then the product is placed at 60°C Dry in ...

Embodiment 2

[0047] 1T-MoS 2 The preparation method of the modified ZnCoS solid solution hollow dodecahedral nanocomposite material, the specific steps are as follows:

[0048] (1) Preparation of metal organic framework material ZnCo-MOF:

[0049] Weigh 184mg of zinc acetate (1mmol) and 1.593g of cobalt acetate (9mmol) and dissolve in 100ml of methanol solution, stir at room temperature until the solute is completely dissolved to obtain a mixed solution of the two metal salts, which is called A solution. Weigh 4.144g of dimethylimidazole (80mmol) and dissolve it in 1600ml of methanol solution, and stir at room temperature until the solute is completely dissolved to obtain B solution. At room temperature, slowly add B solution into A solution, and keep stirring, keep stirring for 24 hours, then let it stand for 6 hours, the reaction product is separated by suction filtration, then washed 3 times with distilled water and 3 times with ethanol, and then the product is placed at 80°C Dry in a...

Embodiment 3

[0055] 1T-MoS 2 The preparation method of the modified ZnCoS solid solution hollow dodecahedral nanocomposite material, the specific steps are as follows:

[0056] (1) Preparation of metal organic framework material ZnCo-MOF:

[0057] Weigh 1.656mg of zinc acetate (9mmol) and 177mg of cobalt acetate (1mmol) and dissolve in 500ml of methanol solution, stir at room temperature until the solute is completely dissolved to obtain a mixed solution of the two metal salts, which is called A solution. Weigh 3.108g of dimethylimidazole (60mmol) and dissolve it in 1800ml of methanol solution, and stir at room temperature until the solute is completely dissolved to obtain B solution. At room temperature, slowly add B solution into A solution, and keep stirring, keep stirring for 24 hours and then let it stand for 8 hours. The reaction product is separated by suction filtration, then washed with distilled water for 3 times and ethanol for 3 times, and then the product is placed at 80°C D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com