Phenolic-resin-modified silicon-based negative electrode material for lithium ion battery and preparation method thereof

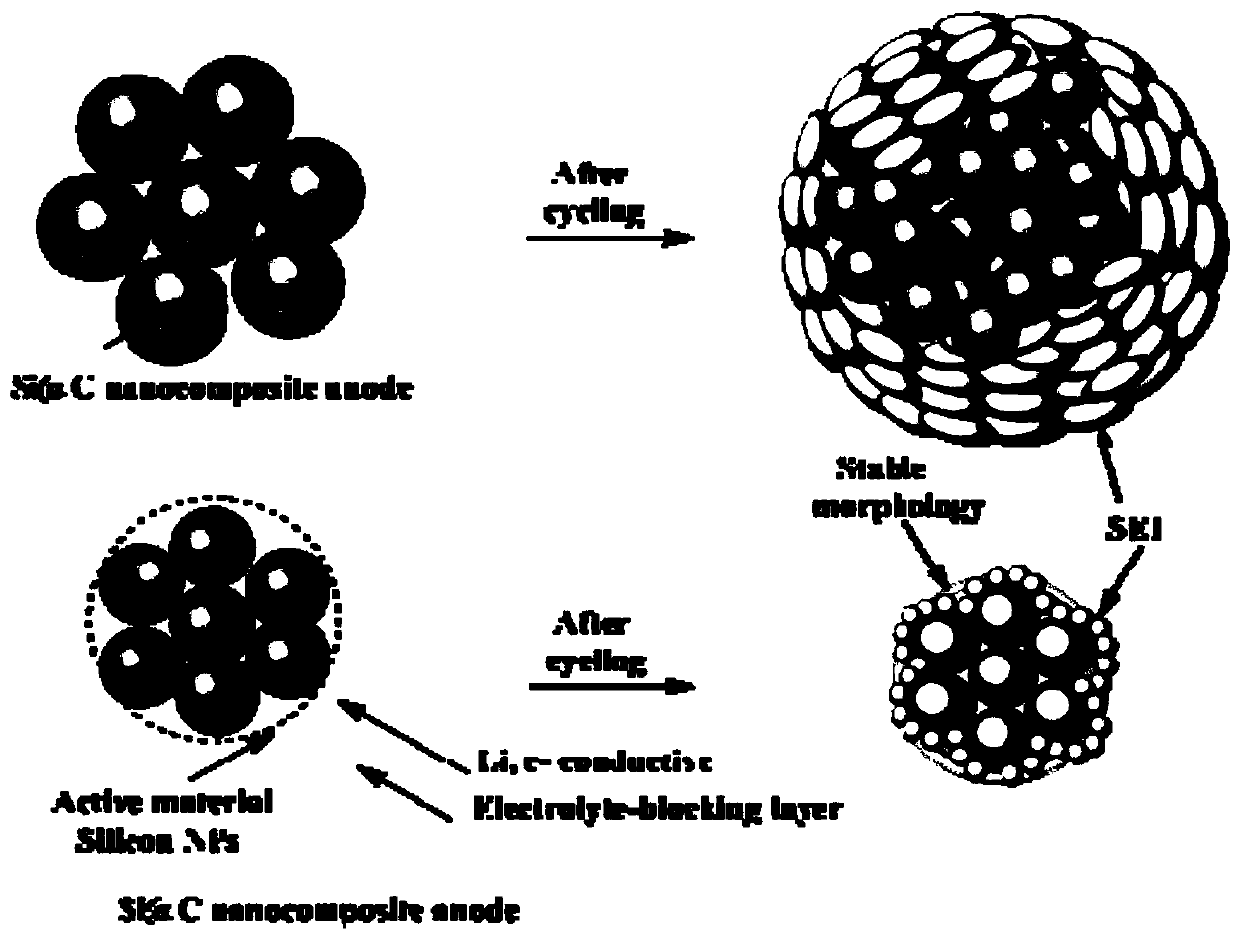

A silicon-based negative electrode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problem of electrode cycle performance degradation, electrode material structure damage, huge volume effect, etc. problems, achieve excellent electrochemical performance, increase reaction sites, and reduce volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

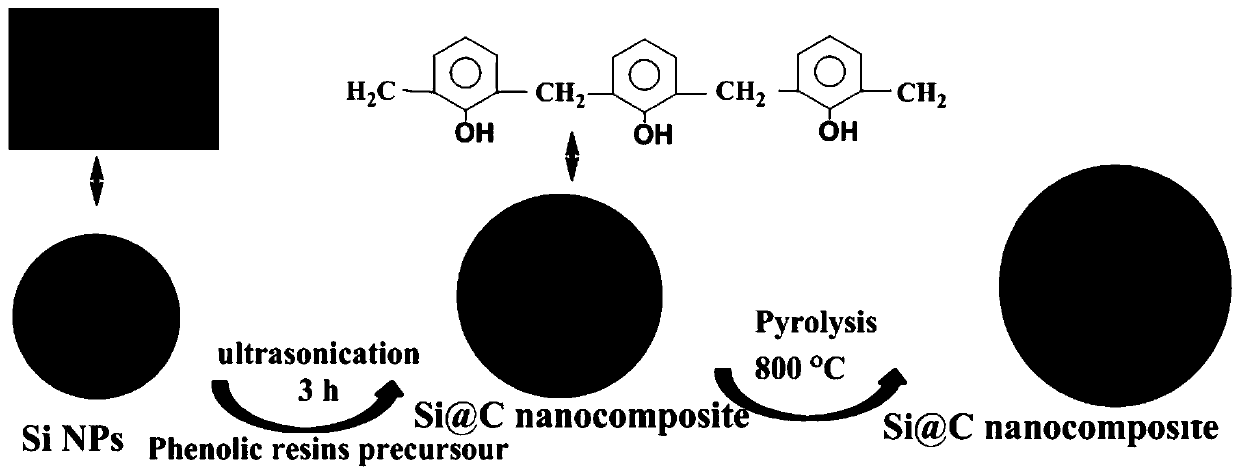

[0033] A preparation method of a lithium-ion battery silicon-based negative electrode material modified by phenolic resin, comprising the following steps:

[0034] Add 0.3g of phenolic resin to 50ml of water, stir until it is completely dissolved, then add 0.1g of silicon nanoparticles with a particle size of 70-130nm, and ultrasonicate at 40°C for 4h to make it evenly mixed. Then 1.5g 2,5-dimercapto-1,3,4-thiadiazole was dissolved in 50ml ethanol to obtain the ethanol solution of 2,5-dimercapto-1,3,4-thiadiazole, and it was mixed with The mixed solution of phenolic resin and silicon nanoparticles was mixed, and then 0.5 g of cetyltrimethylammonium bromide was added under the stirring condition of 500 r / min, and the stirring was continued to avoid agglomeration. Then 6.85 g of ammonium persulfate was dissolved in 50 mL of water to obtain an ammonium persulfate solution, and the ammonium persulfate solution was added dropwise to the above solution at a rate of 2 mL / min. After ...

Embodiment 2

[0036] The method and steps are the same as in Example 1, except that the pyrolysis temperature of the preliminary crosslinked product is 700°C, and the obtained phenolic resin-modified silicon-based negative electrode material for lithium-ion batteries is denoted as Si@IC.

Embodiment 3

[0038] The method and steps are the same as in Example 1, except that the pyrolysis temperature of the preliminary crosslinked product is 800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com