Laser processing method for improving TCO thin film comprehensive optical and electrical properties

A laser processing method and technology of optoelectronic characteristics, applied in the direction of copying/marking method, circuit, electrical components, etc., can solve the problems of conductivity damage, difficult to control corrosion speed and thickness, high sensitivity, improve conductivity and facilitate promotion , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

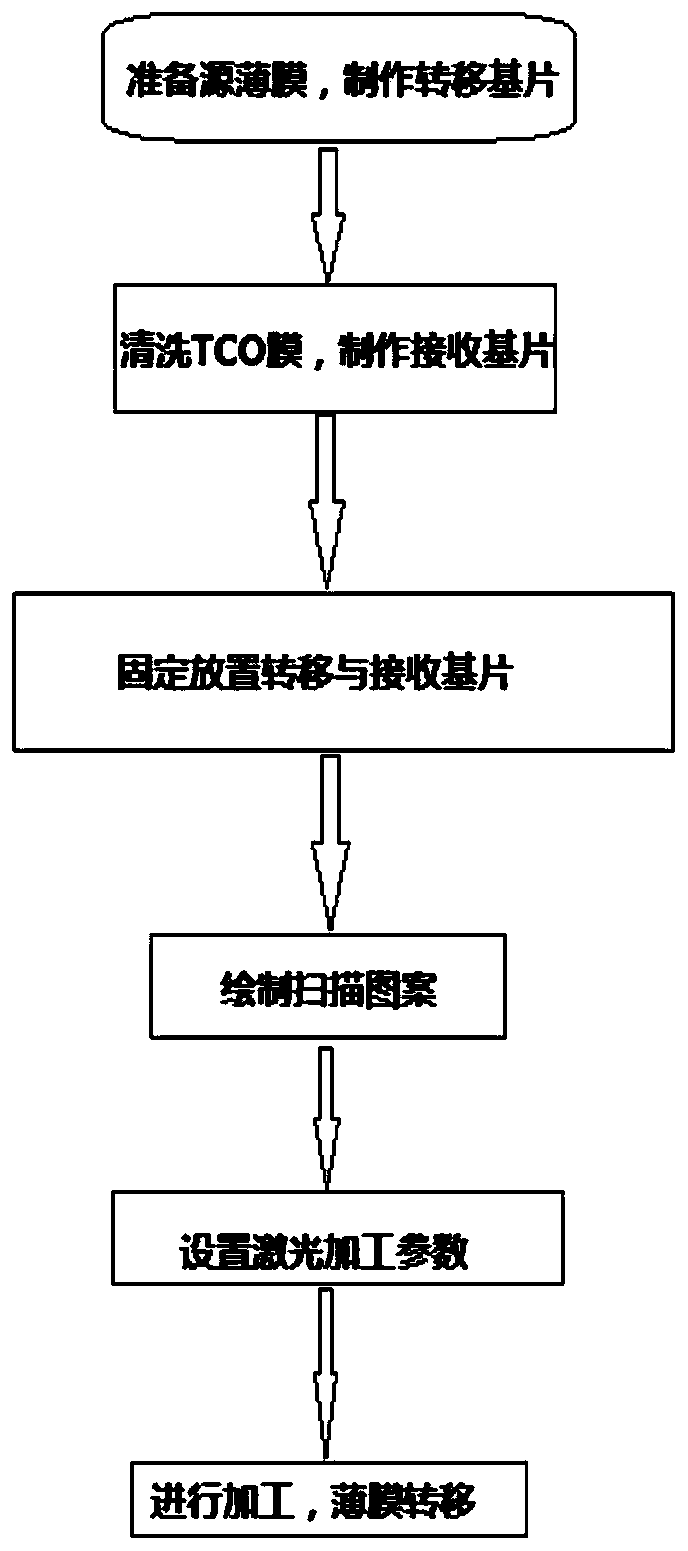

Method used

Image

Examples

Embodiment 1

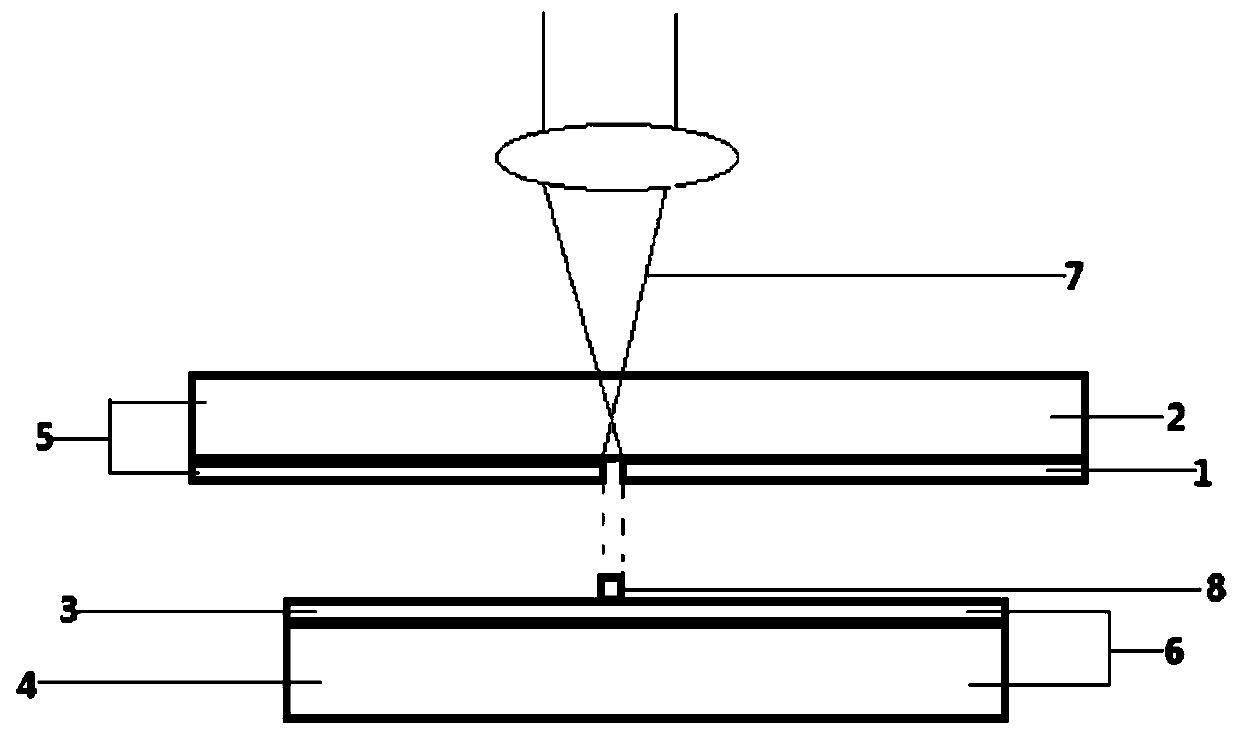

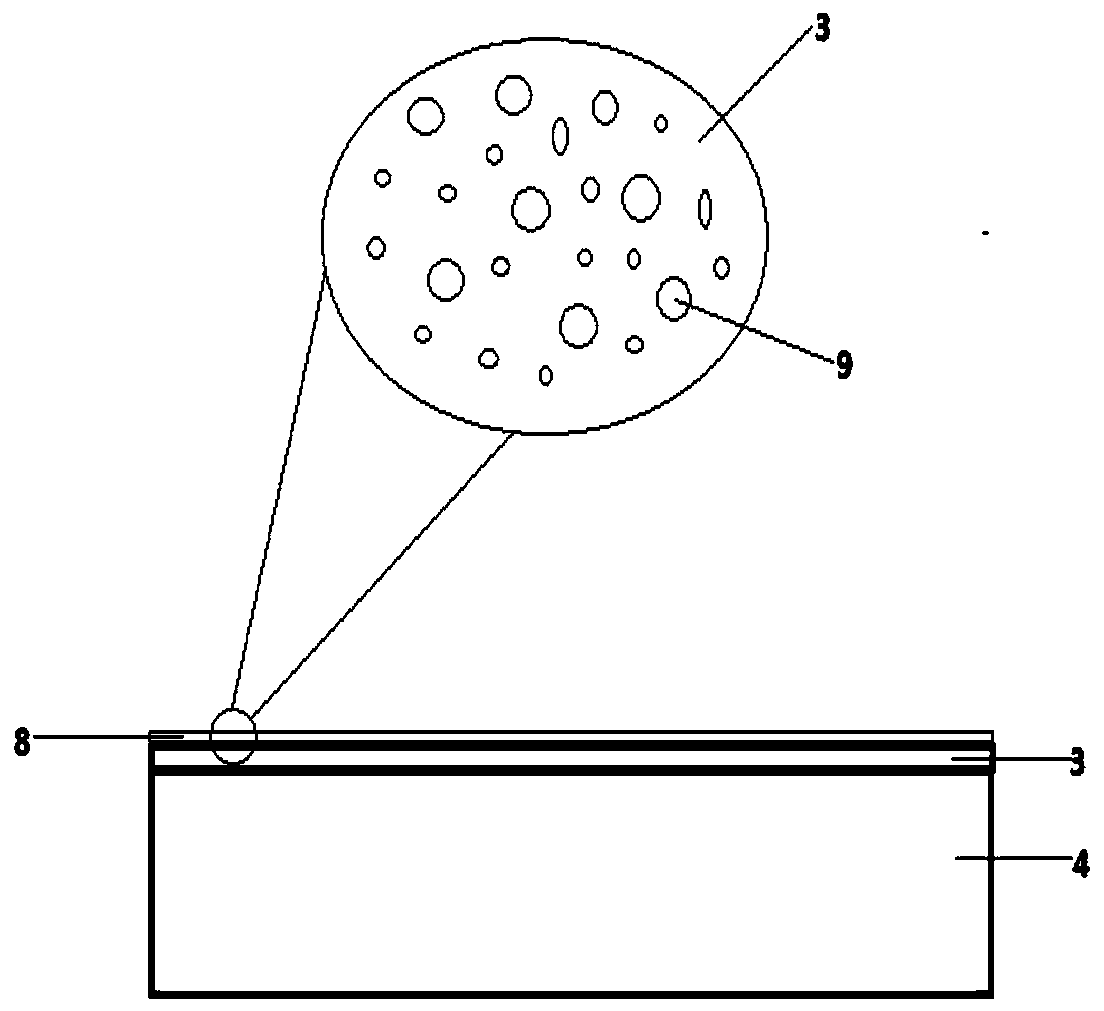

[0030] In this embodiment, the metal material is selected as silver (Ag), and the TCO film is selected as an aluminum-doped zinc oxide (AZO) film, and the photoelectric performance is improved by doping Ag particles on the surface of the AZO film;

[0031] Step 1, the metal Ag to be doped is deposited on the surface of the transfer substrate 2 by vacuum magnetron sputtering. At this time, the metal Ag exists in the form of a film and serves as the source film 1, and the thickness of the film is controlled to 50nm by controlling the sputtering time , the quality of the source film formed in this way is better, and its size is 20×20mm. The source film 1 and the transfer substrate 2 are collectively referred to as the transfer substrate 5;

[0032] Step 2, select AZO to be prepared on the receiving substrate 4, wash it, dry it and use it as the receiving substrate 6; the size of the AZO glass is 15×15×2mm, the transmittance of visible light is 80%, and the square resistance is 9.5...

Embodiment 2

[0041] Silver (Ag) is selected as the metal material, and fluorine-doped tin dioxide (FTO) film is selected as the TCO film, and the photoelectric performance is improved by doping Ag particles on the surface of the FTO film;

[0042] Step 1, the metal Ag to be doped is deposited on the surface of the transfer substrate 2 by vacuum magnetron sputtering. At this time, the metal Ag exists in the form of a film and serves as the source film 1, and the thickness of the film is controlled to 30nm by controlling the sputtering time , the quality of the source film formed in this way is better, and its size is 20×15 mm. The source film 1 and the transfer substrate 2 are collectively referred to as the transfer substrate 5;

[0043] Step 2, select the FTO film to be prepared on the receiving substrate 4, wash it, dry it for standby, and use it as the receiving substrate 6; the size of the FTO film glass is 10×10×1mm, the visible light transmittance is 78.02%, and the square resistance ...

Embodiment 3

[0053] Silver (Ag) is selected as the metal material, aluminum-doped zinc oxide (AZO) film is selected as the TCO film, and the photoelectric performance is improved by doping Ag particles on the surface of the AZO film.

[0054] Step 1, the metal Ag to be doped is deposited on the surface of the transfer substrate 2 by vacuum magnetron sputtering. At this time, the metal Ag exists in the form of a film and serves as the source film 1, and the thickness of the film is controlled to be 100nm by controlling the sputtering time , the quality of the source film formed in this way is better, and its size is 20×20mm. The source film 1 and the transfer substrate 2 are collectively referred to as the transfer substrate 5;

[0055] Step 2, select the AZO film to be prepared on the receiving substrate 4, wash it, dry it and use it as the receiving substrate 6; the size of the AZO glass is 15×15×2mm, the transmittance of visible light is 79.46%, and the square resistance is 9.39Ω / sq, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com