Conjugated polymer containing triphenylamine structure and tetraphenyl ethylene unit, preparation method thereof, and applications of conjugated polymer in electrochromism

A technology of conjugated polymers and tetraphenylethylene, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of poor stability of electrochromic materials, achieve good electrochromic properties, enhance hole transport capabilities, expand The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

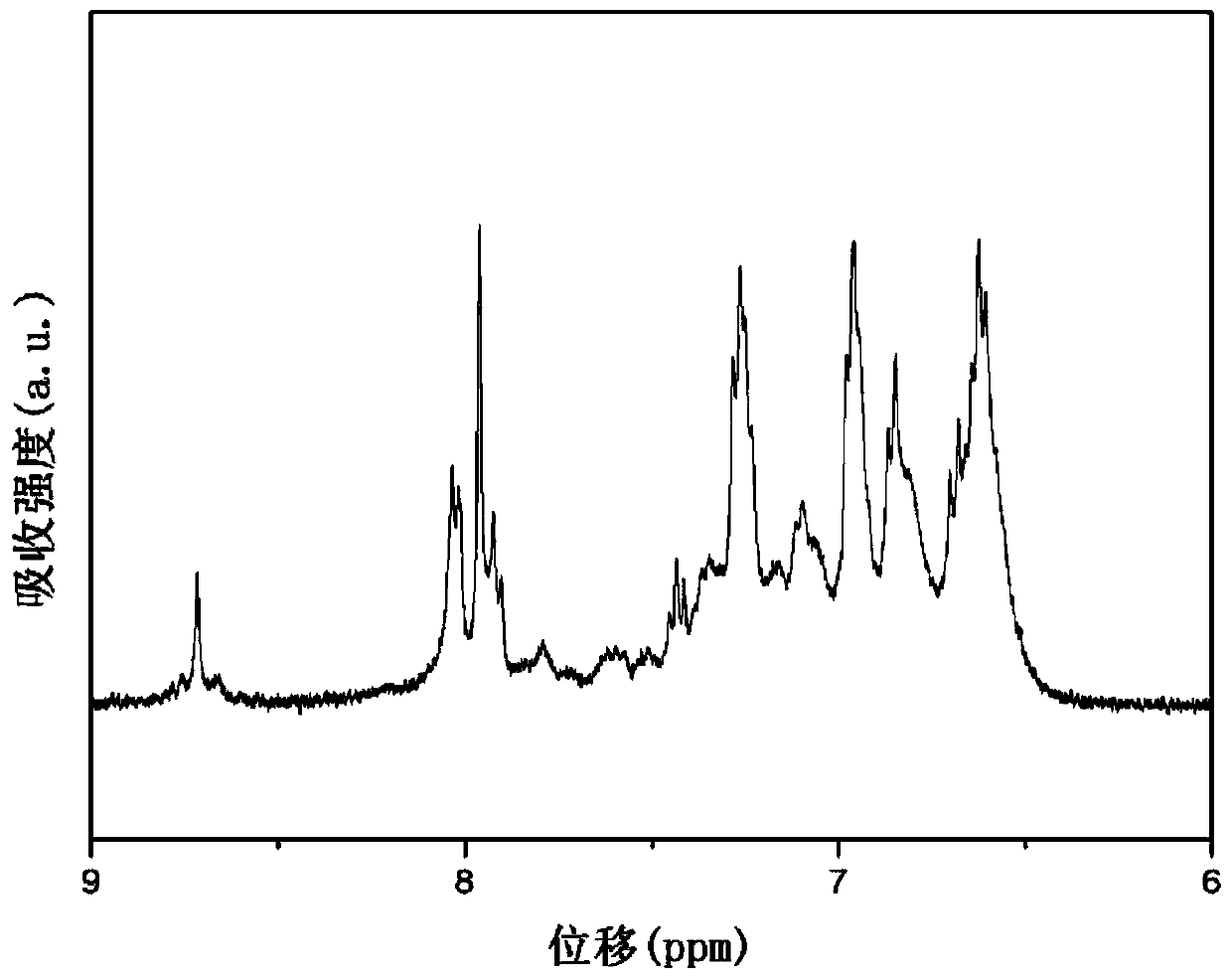

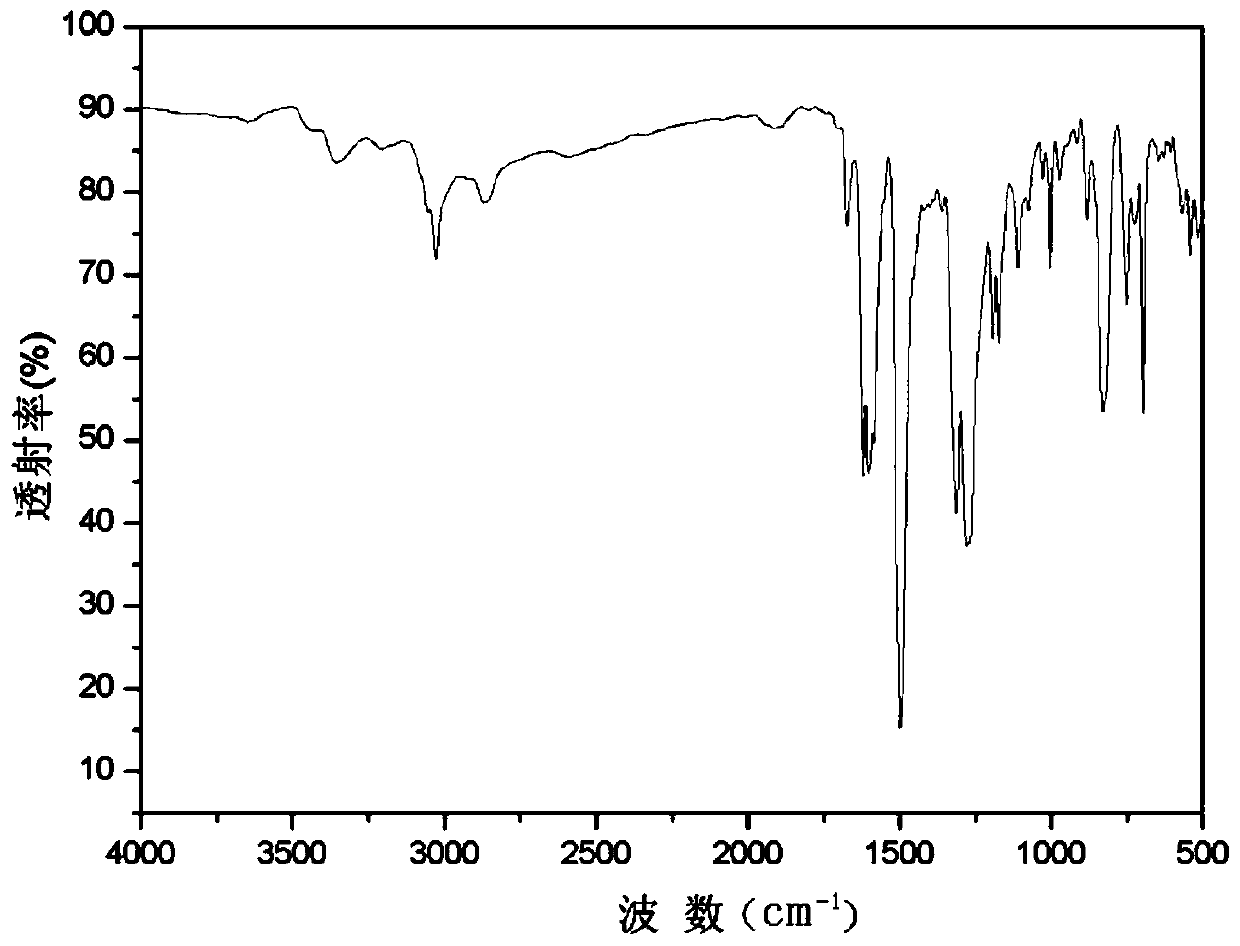

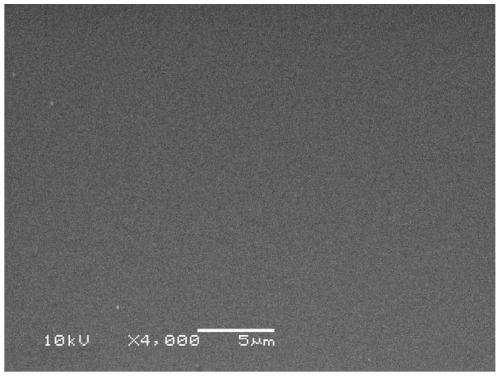

[0030] Embodiment 1: The structural formula of the conjugated polymer containing triphenylamine structure and tetraphenylethylene unit in this embodiment is:

[0031] In the formula, n is a positive integer.

[0032] The principles and beneficial effects of this embodiment are:

[0033] 1. The conjugated polymer containing triphenylamine structure and tetraphenylethylene unit in this embodiment belongs to the poly-Schiff base polymer material. Due to its heat resistance and electrical conductivity, it expands the application range of electrochromic materials . Compared with other conductive polymers, the conjugated polymer containing triphenylamine structure and tetraphenylethylene unit introduces heteroatom nitrogen containing unbonded electron pairs on the main conjugated chain, which makes the charge distribution and energy band of the polymer The characteristics have changed greatly, increasing the degree of delocalization of electrons in the molecule, and improving so...

specific Embodiment approach 2

[0037] Specific embodiment two: the preparation method of the conjugated polymer containing triphenylamine structure and tetraphenylethylene unit in this embodiment is specifically carried out according to the following steps:

[0038] 1. Synthesis of dibromotetraphenylethylene:

[0039] Add 4-bromobenzophenone, zinc powder and anhydrous tetrahydrofuran in sequence in the three-necked flask and stir evenly. After flushing with nitrogen three times, cool to -5~0°C; Add titanium tetrachloride dropwise through the constant pressure dropping funnel under the same conditions, and continue stirring for 30-40 minutes; after the system temperature naturally rises to room temperature, transfer the three-necked bottle to a constant temperature water bath, and heat the constant temperature water bath to 80-85°C And reflux for 22-24 hours, stop heating, and naturally cool to room temperature under nitrogen atmosphere; place the cooled reaction solution in 9%-10% potassium carbonate aqueou...

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the ratio of the amount of substances of 4-bromobenzophenone and zinc powder described in step one is 1: (1.9~2.1); 4-bromodiphenone The volume ratio of the substance amount of benzophenone to anhydrous tetrahydrofuran is 1mol:(5.15~5.25)L; the ratio of the substance quantity of 4-bromobenzophenone and titanium tetrachloride is 1:(0.98~1.01) ; Anhydrous tetrahydrofuran and potassium carbonate aqueous solution volume ratio of 1: (5 ~ 5.5). Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com