Preparation method and application of high activity biological pesticide microcapsule sustained release agent

A biopesticide and slow-release agent technology, which is applied in the field of preparation of highly active biopesticide microcapsule sustained-release agents, can solve the problems of low stability of microbial source pesticides, low bacterial count and spore rate, easy death and inactivation of microorganisms, etc. Problems, to achieve the effect of increasing storage stability, improving stability, and increasing growth metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fermentation culture of embodiment 1 bacillus

[0033] 1) Strain activation: Under sterile conditions, the preserved strains of Bacillus cyclocereus (preservation number ACCC BCBKL 0055) and Bacillus amyloliquefaciens (preservation number ACCC 60428) were transferred to LB slant medium, placed in Cultivate at a constant temperature of 30°C for 12 hours, and transfer 3 times in this way to restore the activity of the bacteria.

[0034] 2) Preparation of seed solution: Take the activated Bacillus cereus and Bacillus amyloliquefaciens, and inoculate them into the seed medium with 2% inoculum respectively (the ingredients are beef extract 5g / L, yeast extract 5g / L, peptone 10g / L L, Glucose 5g / L, NaCl 5g / L, K 2 HPO 4 1.5g / L, pH adjusted to 7.0) for shake flask culture for 24h. During the cultivation process, low-frequency electromagnetic field radiation was applied to the seed solution every 3h for 1h. The parameters of the low-frequency electromagnetic field were freq...

Embodiment 2

[0038] The optimization of embodiment 2 fermentation culture conditions

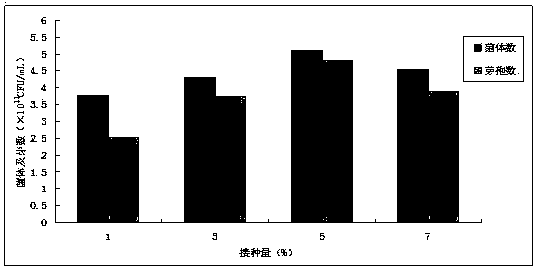

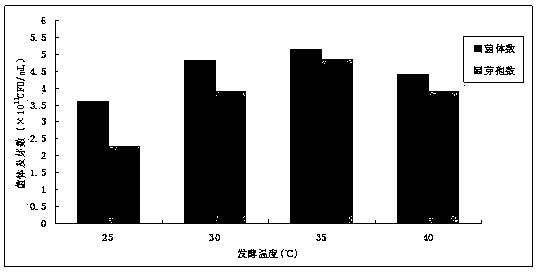

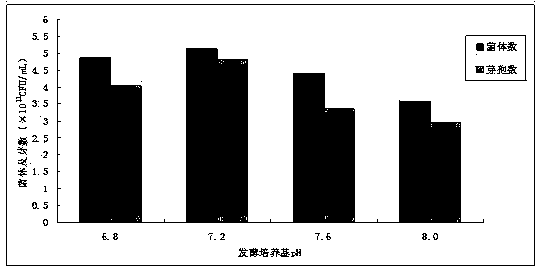

[0039] 1) Influence of the inoculum amount on the number of bacteria and spores: set the total inoculum amount of the seed liquid in Example 1 to 1%, 3%, 5%, and 7% respectively, and the other conditions are the same. After the fermentation, take the fermentation liquid Carry out the detection of bacterial cell number and spore number, the result is as follows: figure 1 shown. When the inoculation amount increases, the bacteria will grow rapidly and form spores, but when the inoculum amount exceeds a certain range, due to the competition between the microorganisms for the living space and the nutrient content of the medium, excessive metabolic waste will be produced at the same time, which will affect the continued proliferation of the bacteria and Further transformation of spores. From figure 1 It can be seen that the number of bacteria and spores is the highest when the inoculation amount is 5%, a...

Embodiment 3

[0054] The preparation of embodiment 3 microcapsule sustained release agent

[0055] 1) Preparation of microcapsule cores: take the fermentation broth in Example 1 and centrifuge at 4°C and 4000r / min for 15min, remove the supernatant, wash the cell pellet 2-3 times with sterile normal saline, and then Resuspend in 1.5% trehalose solution to make microcapsule core.

[0056] 2) Preparation of microcapsule sustained-release agent: Weigh β-cyclodextrin and dissolve it in an appropriate amount of distilled water, heat it in a water bath at 50°C, and stir it magnetically for a period of time until it is completely dissolved to form a saturated aqueous solution as the microcapsule wall material. The microcapsule core is added to the above-mentioned microcapsule wall material at a ratio of 1:8 (V / V), and then placed in an ultrasonic oscillator for auxiliary coating treatment. The conditions are that the ultrasonic temperature is 60°C and the ultrasonic time is 50min. After the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com