Preparation method of halogen bismuth oxide nitrogen fixation photocatalysts with three-dimensional structure

A bismuth oxyhalide and photocatalyst technology, which is applied in the field of new energy material preparation, can solve the problems of difficulty in large-scale production, serious environmental pollution, and high cost, and achieve the effects of high solar energy utilization efficiency, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

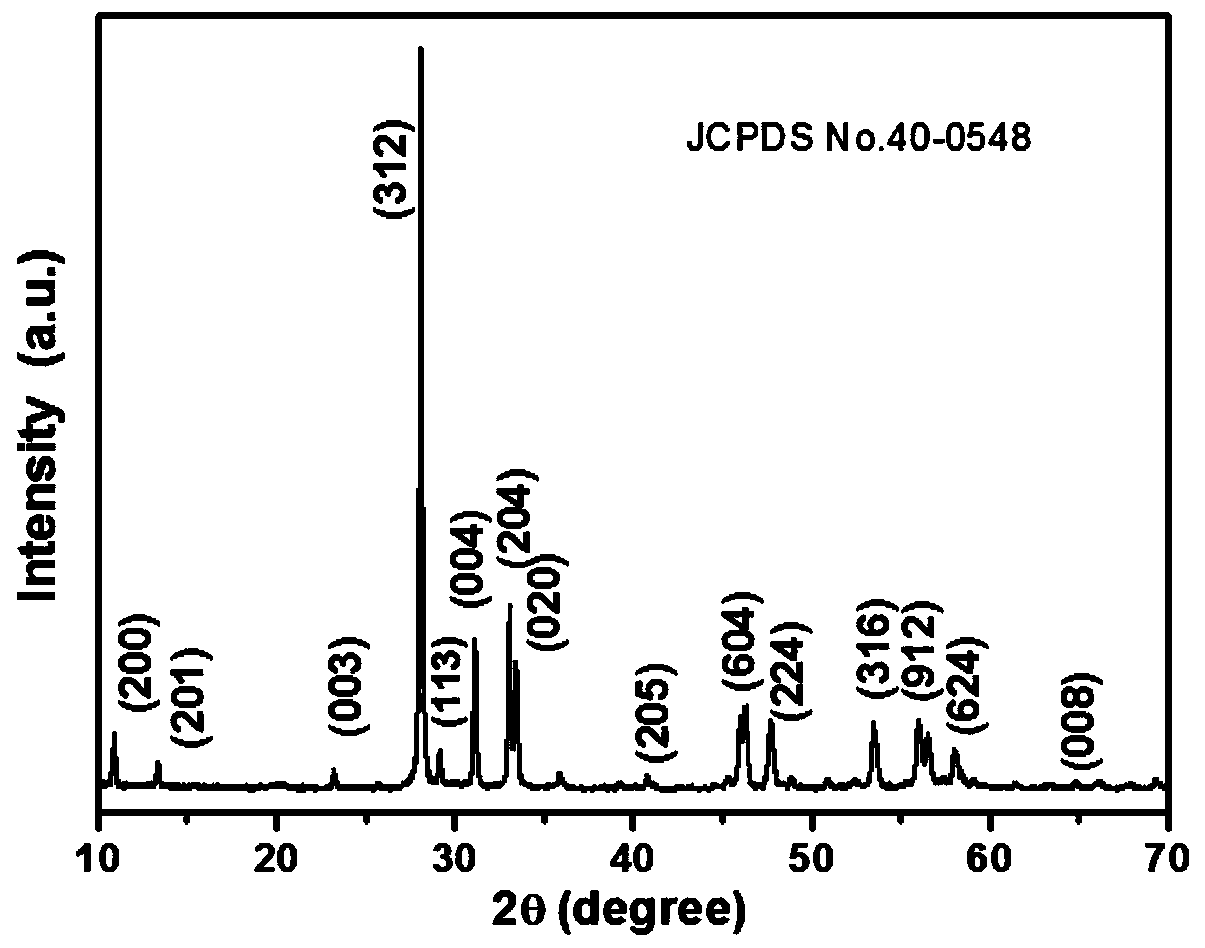

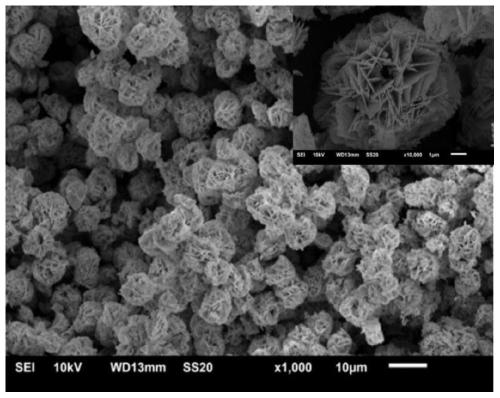

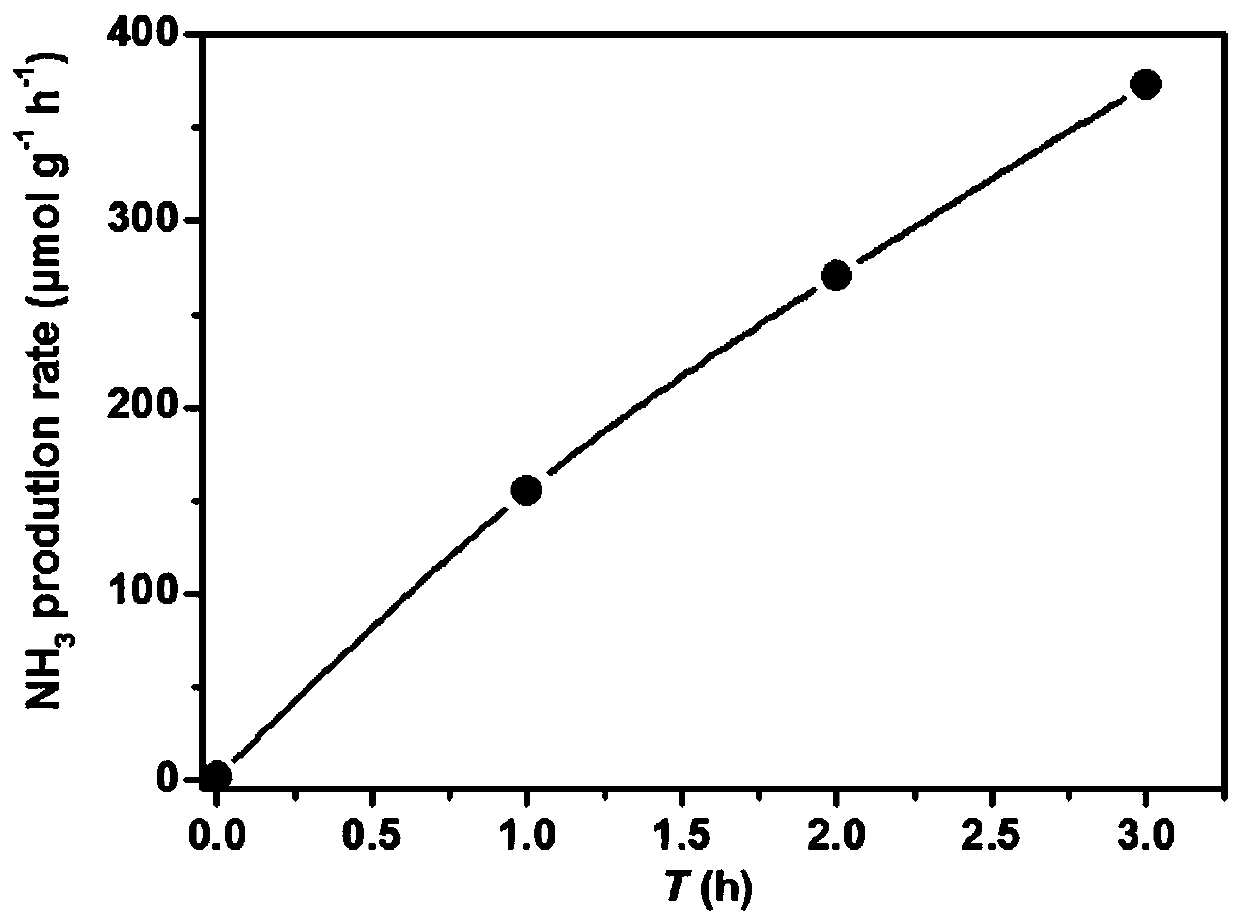

[0039] A three-dimensional hollow photocatalytic nitrogen fixation catalyst Bi 5 o 7 The preparation method of I, comprises the steps:

[0040] (1) Weigh 5g of glucose and place it in 60ml of deionized water, and obtain a uniform glucose aqueous solution after magnetic stirring;

[0041] (2) Transfer the aqueous glucose solution of step (1) to a 100ml reactor, carry out a hydrothermal reaction at a temperature of 180°C for 12h, then wash the product of the hydrothermal reaction with deionized water and ethanol respectively, and Centrifuge 4 times at 6000 rpm for 5 minutes, then dry at 60°C for 24 hours to obtain mesophase carbon microspheres;

[0042] (3) 0.5 g of the mesophase carbon microspheres obtained in step (2) is weighed and placed in a beaker containing 200 ml and a concentration of 1.5 mol / L of acetic acid aqueous solution, and then magnetically stirred to make it evenly dispersed;

[0043] (4) Add 0.02mol of Bi(NO 3 ) 3 ·5H 2 0, until completely dissolving, th...

Embodiment 2

[0047] A three-dimensional hollow photocatalytic nitrogen fixation catalyst Bi 5 o 7 The preparation method of I, comprises the steps:

[0048] (1) Weigh 3g of glucose and place it in 30ml of deionized water, and obtain a uniform glucose aqueous solution after magnetic stirring;

[0049] (2) Transfer the aqueous glucose solution of step (1) to a 50ml reactor, carry out a hydrothermal reaction at a temperature of 180°C for 12h, then wash the product of the hydrothermal reaction with deionized water and ethanol respectively, and Centrifuge 4 times at 6000 rpm for 5 minutes, then dry at 60°C for 24 hours to obtain mesophase carbon microspheres;

[0050] (3) 0.4 g of the mesophase carbon microspheres obtained in step (2) is weighed and placed in a beaker containing 120 ml and a concentration of 1.2 mol / L of acetic acid aqueous solution, and then magnetically stirred to make it evenly dispersed;

[0051] (4) Add 0.015mol of Bi(NO 3 ) 3 ·5H 2 0, until fully dissolved, add 0.01...

Embodiment 3

[0055] A three-dimensional hollow photocatalytic nitrogen fixation catalyst Bi 5 o 7 The preparation method of I, comprises the steps:

[0056] (1) Weigh 6g of glucose and place it in 60ml of deionized water, and obtain a uniform glucose aqueous solution after magnetic stirring;

[0057] (2) Transfer the aqueous glucose solution of step (1) to a 100ml reactor, carry out a hydrothermal reaction at a temperature of 180°C for 12h, then wash the product of the hydrothermal reaction with deionized water and ethanol respectively, and Centrifuge 4 times at 6000 rpm for 5 minutes, then dry at 60°C for 24 hours to obtain mesophase carbon microspheres;

[0058] (3) 0.3 g of the mesophase carbon microspheres obtained in step (2) is weighed and placed in 60 ml of acetic acid aqueous solution with a concentration of 1 mol / L, and magnetically stirred to uniformly disperse it;

[0059] (4) Add 0.01mol of Bi(NO 3 ) 3 ·5H 2 0, add 0.01mol of KI after dissolving completely, obtain brown p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com