Heavy metals-tolerant bacterial agent, preparation method thereof and application of heavy metals-tolerant bacterial agent in wastewater treatment

A technology of heavy metal and bacterial agents, which is applied in heavy metal-resistant bacterial agents, preparation, and sewage treatment. It can solve the problems of weak resistance to environmental impact, high requirements for storage conditions, and poor ecological stability. It achieves fast sedimentation rate, Effect of tolerance to heavy metal ions and improvement of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The skeleton network of the heavy metal-resistant bacterial agent is composed of sodium alginate, sodium bicarbonate, diatomaceous earth, ammonia water and calcium nitrate, and its mass ratio is 42:16:24:2:16; Layer network, distribution of a large number of inorganic mineral particles.

[0047] The microbial agent is embedded with microorganisms that can efficiently remove organic matter, ammonia nitrogen and total nitrogen in sewage. The prepared bacterial agent is in the shape of grayish-yellow microspheres, with a density slightly higher than that of water. The sedimentation rate in water is fast and the solid-liquid separation efficiency is high; The bacteria agent particles uniformly distribute a large number of calcium ions in the internal space, which can interact with heavy metal ions (Cu 2+ , Zn 2+ , Cd 2+ ) undergoes ion exchange, thereby fixing heavy metal ions to the internal network of the bacterial agent, protecting the microbial activity embedded insid...

Embodiment 2

[0056] The heavy metal-resistant bacterial agent is prepared according to the preparation method described in Example 1 to obtain the heavy metal-resistant bacterial agent;

[0057] The difference from Example 1 is that the present embodiment specifically describes the application of the heavy metal-resistant bacterial agent in the biofilm method, including the following steps:

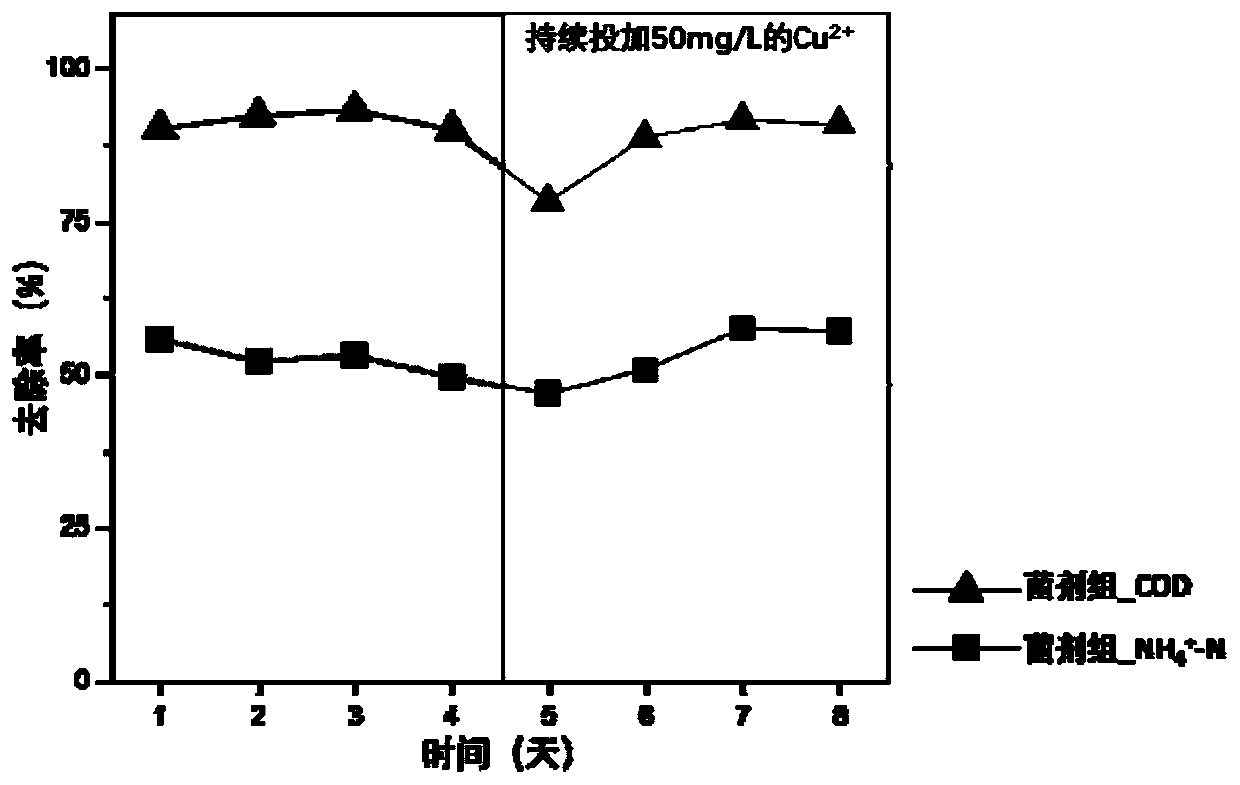

[0058] 1) Use plexiglass to make a rectangular reactor with a volume of 110 liters without a cover, and use a peristaltic pump to add 100 liters of fresh urban sewage containing heavy metal pollution to the reactor (influent water quality requirements: COD Cr 150-250 mg / L, ammonia nitrogen 20-30 mg / L, Cu 2+ Less than 100 mg / liter, and add 1 liter of gel microspheres obtained in Example 1;

[0059] 2) A silicone aeration head with a diameter of 90 mm is placed in the center of the bottom of the reactor, and compressed air is supplied by an air compressor pump, and the aeration rate is adjusted to 50 ...

Embodiment 3

[0063] The heavy metal-resistant bacterial agent is prepared according to the preparation method described in Example 1 to obtain the heavy metal-resistant bacterial agent;

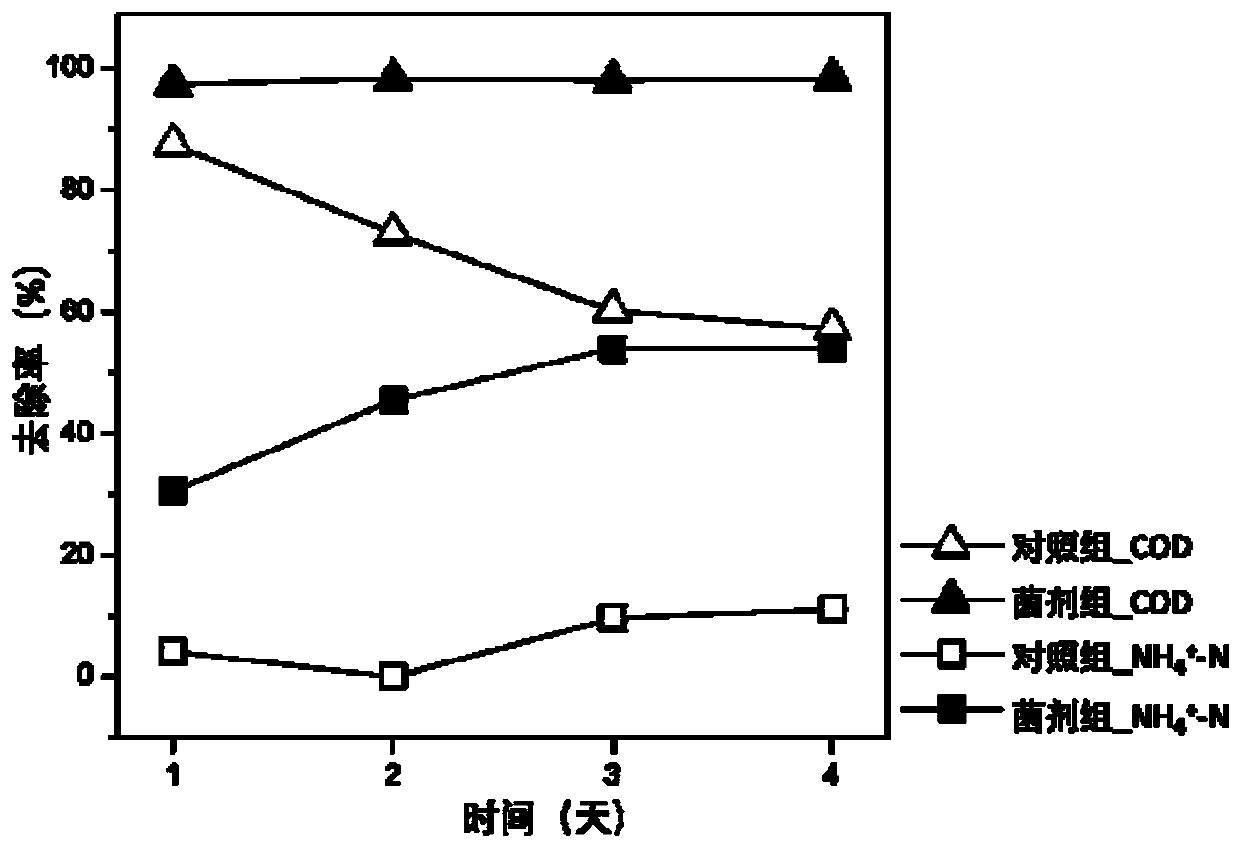

[0064] The difference from Examples 1 and 2 is that the present embodiment specifically describes the application of the heavy metal-resistant bacterial agent in the activated sludge process, including the following steps:

[0065] 1) Use plexiglass to make a rectangular reactor with a volume of 110 liters without a cover, and use a peristaltic pump to add 100 liters of fresh urban sewage containing heavy metal pollution to the reactor, and the quality of the influent water is: COD Cr 200-600 mg / L, ammonia nitrogen 20-80 mg / L, Cu 2+ <250 mg / L;

[0066] 2) add 200 milliliters of gel microspheres that obtain in embodiment 1 in the reactor, and 30L are collected from the activated sludge of city sewage treatment plant aeration tank;

[0067] 3) A silicone aeration head with a diameter of 90 mm is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com