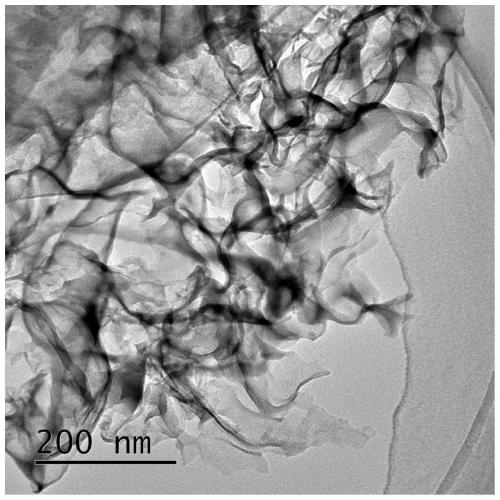

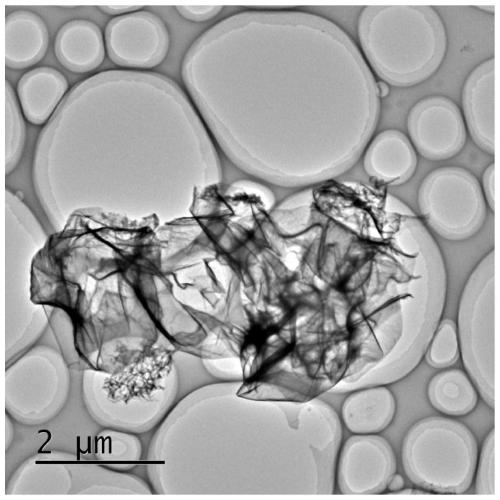

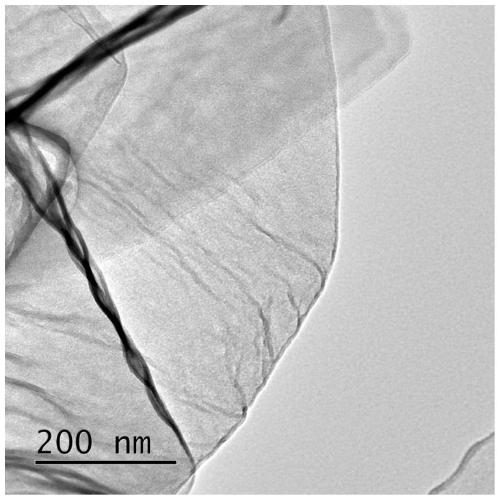

Preparation method of two-dimensional porous titanium dioxide nanosheet

A technology of porous titanium dioxide and nanosheets, which is applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of good crystallinity, improved performance, and increased reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of porous titanium dioxide nanosheets, comprising the following steps:

[0042] (1) Add titanium tetrachloride to the ammonium chloride aqueous solution with a molar concentration of 3.12mol / L (volume ratio is 1:100). Since titanium tetrachloride is easily hydrolyzed when heated, the ammonium chloride aqueous solution should be placed in Cool down in an ice-water bath, then slowly add titanium tetrachloride solution, keep stirring at a constant speed to prevent insufficient dissolution, and form a transparent mixed solution M1;

[0043] (2) Add 1g of dicyandiamide to 20mL of ammonium chloride aqueous solution with a molar concentration of 4.6mol / L. Since dicyandiamine is not easily soluble in water at room temperature (25°C), it has a high solubility in hot water ; But when heated to 80°C, a decomposition reaction will occur to produce ammonia (NH 3 ). In order to quickly dissolve dicyandiamine without decomposition reaction, first heat the ammoni...

Embodiment 2

[0050] A preparation method of porous titanium dioxide nanosheets, except that the volume ratio of titanium tetrachloride and ammonium chloride aqueous solution is changed to 0.5:100 in step (1), other operations are the same as in Example 1, and porous titanium dioxide nanosheets are prepared. piece.

Embodiment 3

[0052] A preparation method of porous titanium dioxide nanosheets, except that the volume ratio of titanium tetrachloride and ammonium chloride aqueous solution is changed to 2:100 in step (1), other operations are all the same as in Example 1, and porous titanium dioxide nanosheets are prepared. piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com