Epoxy resin-based LED packaging material preparation method

A technology of LED encapsulation and epoxy resin, applied in the field of preparation of light-emitting semiconductor encapsulation materials, can solve the problems of low impact toughness, prone to yellowing, brittleness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

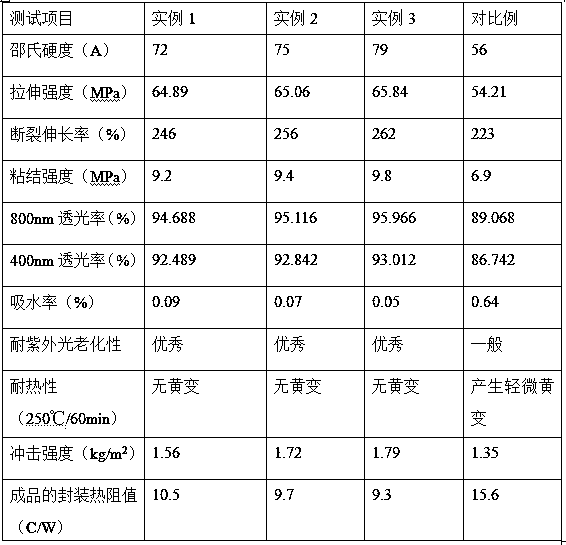

Examples

Embodiment Construction

[0021] Put rice husk, biogas slurry and glycine in a mass ratio of 1:5:1 and put them into a fermenter, seal the mouth of the tank and place it at a temperature of 35-45°C for 9-11 days of sealed fermentation. Filtration and separation to obtain fermentation filter residue, put the fermentation filter residue into a carbonization furnace, and carbonize at a temperature of 400-450°C for 1-2 hours under the protection of nitrogen to obtain carbonized fermentation filter residue; mix the above-mentioned carbonized fermentation filter residue and hydrogen-containing silicone oil in an equal mass ratio Then put it into the calcination furnace, feed argon gas into the calcination furnace until all the air in the furnace is replaced, heat up to 1600-1800°C, keep the heat for sintering for 5-7 hours, take out the sintered product, and use 20% hydrofluoric acid Rinse for 15 to 20 minutes to obtain porous silicon carbide whiskers; mix porous silicon carbide fibers and a sodium silicate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com