Copper oxide-cuprous oxide photocatalyst and preparation method thereof

A technology of cuprous oxide and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of cumbersome operation, high cost, high reaction conditions and device requirements, and achieve the effects of easy-to-obtain raw materials, simple operation and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

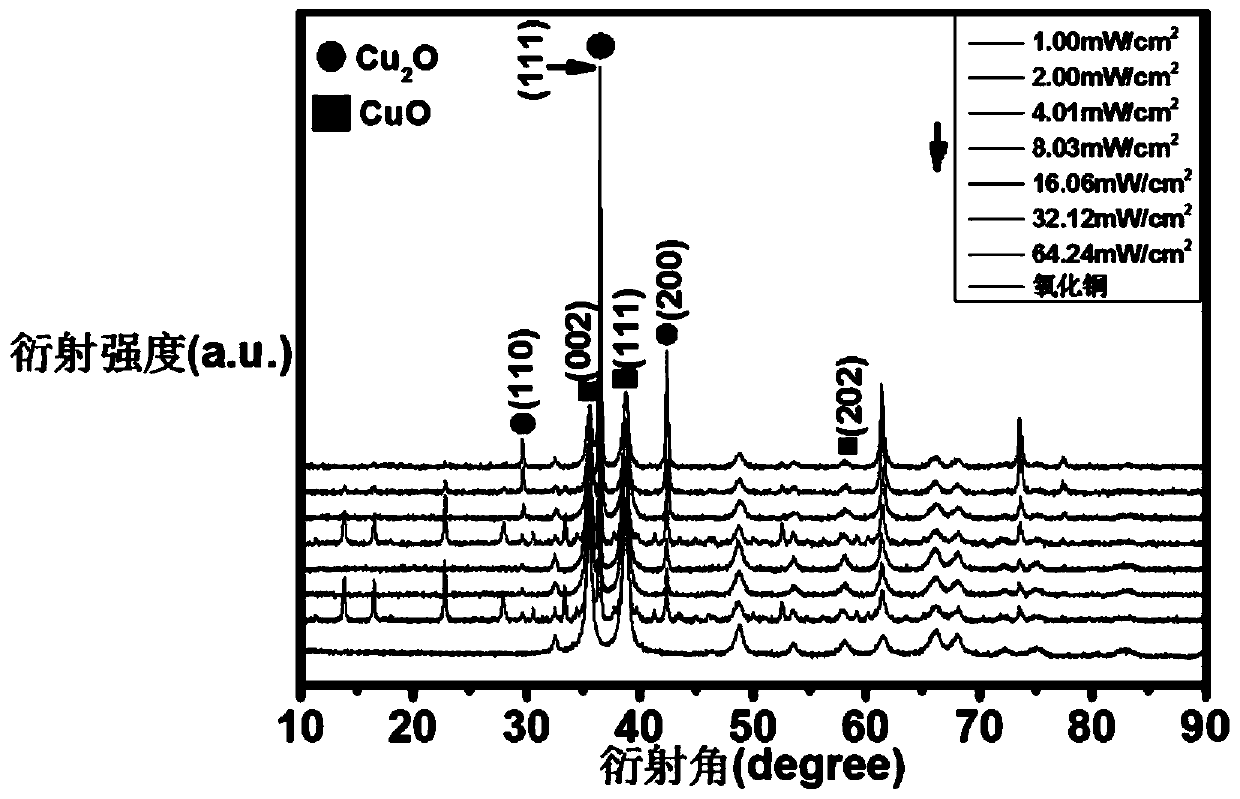

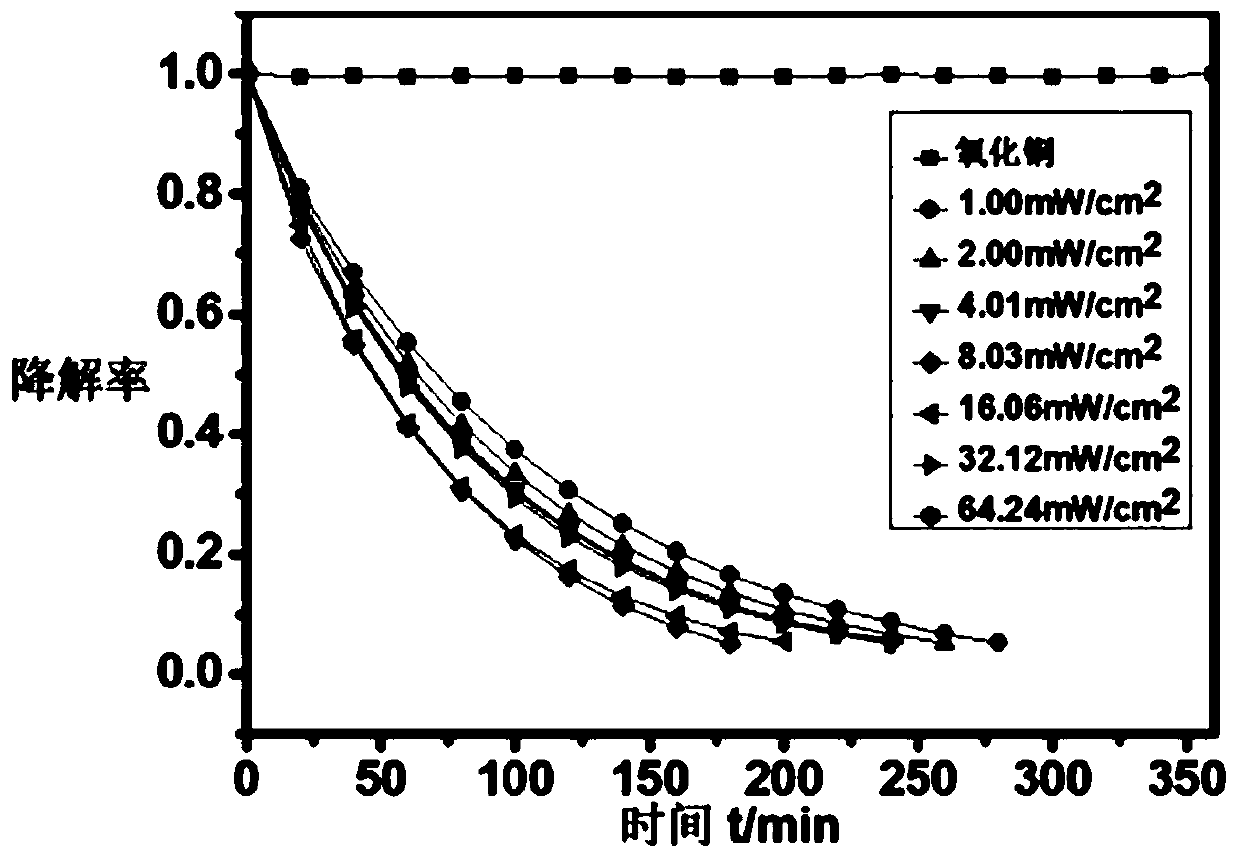

[0027] A preparation method of copper oxide-cuprous oxide photocatalyst:

[0028] 1) Dissolve 1.0g of copper sulfate with 80mL of deionized water to obtain a copper sulfate solution, then add 3.2mL of 25% ammonia water dropwise to the copper sulfate solution with a pipette to obtain a precursor solution, and transfer it to a quartz bottle;

[0029] 2) Nitrogen treatment of the quartz bottle for 3~5 minutes;

[0030] 3) After the nitrogen treatment, put it in a constant temperature water bath, and carry out ultraviolet light, and the irradiation intensity of the ultraviolet lamp is 1.00 mW / cm 2 , so that the mixed solution forms a precipitate;

[0031] 4) Centrifuge the precipitate, and then wash the precipitate repeatedly with distilled water until it is neutral, and place the washed precipitate in a constant temperature drying oven to dry to obtain the product cupric oxide-cuprous oxide photocatalyst.

Embodiment 2

[0033] A preparation method of copper oxide-cuprous oxide photocatalyst:

[0034] 1) Dissolve 1.0g of copper sulfate with 80mL of deionized water to obtain a copper sulfate solution, then add 3.2mL of 25% ammonia water dropwise to the copper sulfate solution with a pipette to obtain a precursor solution, and transfer it to a quartz bottle;

[0035] 2) Nitrogen treatment of the quartz bottle for 3~5 minutes;

[0036] 3) After the nitrogen treatment, put it in a constant temperature water bath, and carry out ultraviolet light, and the irradiation intensity of the ultraviolet lamp is 2.00 mW / cm 2 , so that the mixed solution forms a precipitate;

[0037] 4) Centrifuge the precipitate, and then wash the precipitate repeatedly with distilled water until it is neutral, and place the washed precipitate in a constant temperature drying oven to dry to obtain the product cupric oxide-cuprous oxide photocatalyst.

Embodiment 3

[0039] A preparation method of copper oxide-cuprous oxide photocatalyst:

[0040] 1) Dissolve 1.0g of copper sulfate with 80mL of deionized water to obtain a copper sulfate solution, then add 3.2mL of 25% ammonia water dropwise to the copper sulfate solution with a pipette to obtain a precursor solution, and transfer it to a quartz bottle;

[0041] 2) Nitrogen treatment of the quartz bottle for 3~5 minutes;

[0042] 3) After the nitrogen treatment, put it in a constant temperature water bath, and carry out ultraviolet light, and the irradiation intensity of the ultraviolet lamp is 4.01 mW / cm 2 , so that the mixed solution forms a precipitate;

[0043] 4) Centrifuge the precipitate, and then wash the precipitate repeatedly with distilled water until it is neutral, and place the washed precipitate in a constant temperature drying oven to dry to obtain the product cupric oxide-cuprous oxide photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com