A solid resin and application for preparing carbon fiber composite materials

A technology for curing resin and composite materials, applied in the field of curing resin for preparing carbon fiber composite materials, can solve the problems of excess low-end products, insufficient high-end products, lack of competitiveness, etc., achieve high production efficiency, fast reaction molding speed, and avoid agglomeration effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

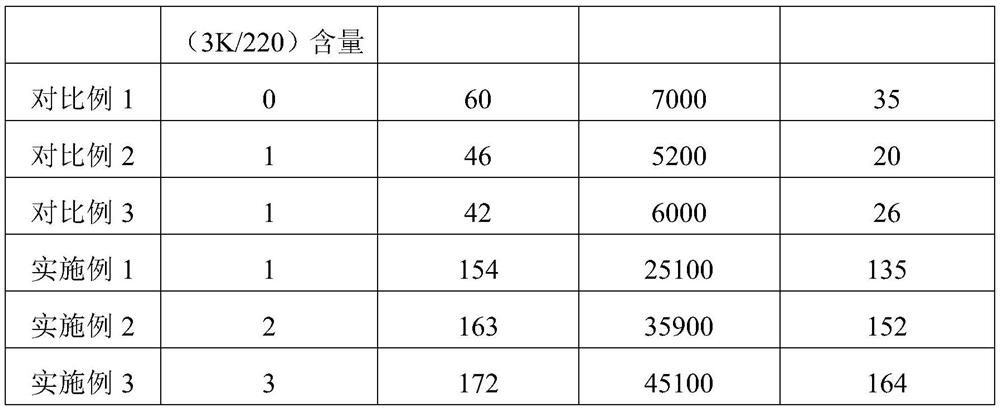

Embodiment 1

[0051] The carbon fiber reinforced olefin polymer material in Example 1 is prepared by vacuum infusion process using olefin polymer monomer, catalyst, inorganic components, organic polymer additives and carbon fiber cloth (3K / 220g) as raw materials. The olefin polymer monomer is a polymerization grade, specifically dicyclopentadiene monomer; the catalyst is a catalyst toluene solution, which is a one-component catalyst and is a complex of Ru transition metals; the mass ratio of the olefin polymer monomer to the catalyst is 1000:1; the addition amount of the inorganic component is 5% of the mass of the olefin polymer monomer, and the addition amount of the organic macromolecular additive is 10% of the mass of the olefin polymer monomer; the inorganic component is nano-montmorillonite, and the organic The macromolecular auxiliary is a silane-containing coupling agent; the reaction temperature of vacuum perfusion is 35℃, and the reaction time is 15min. The amount of carbon fiber ...

Embodiment 2

[0054] The carbon fiber reinforced olefin polymer material in Example 2 is prepared by vacuum infusion process using olefin polymer monomer, catalyst, inorganic components, organic polymer additives and carbon fiber cloth (3K / 220g) as raw materials. The olefin polymer monomer is a polymerization grade, specifically dicyclopentadiene monomer; the catalyst is a catalyst toluene solution; it belongs to a one-component catalyst, which is a complex compound of Ru transition metal; the mass ratio of the olefin polymer monomer to the catalyst is 1000:1; the addition amount of the inorganic component is 5% of the mass of the olefin polymer monomer, and the addition amount of the organic polymer additive is 10% of the mass of the olefin polymer monomer; the inorganic component is kaolin, and the organic polymer auxiliary The agent is a high molecular polymer of hydroxymethyl cellulose; the reaction temperature of vacuum infusion is 35°C. The amount of carbon fiber cloth added is twice ...

Embodiment 3

[0058] The carbon fiber reinforced olefin polymer material in Example 3 is prepared by vacuum infusion process using olefin polymer monomer, catalyst, inorganic components, organic polymer additives and carbon fiber cloth (3K / 220g) as raw materials. The olefin polymer monomer is a polymerization grade, specifically dicyclopentadiene monomer; the catalyst is a catalyst toluene solution; it belongs to a one-component catalyst, which is a complex compound of Ru transition metal; the mass ratio of the olefin polymer monomer to the catalyst is 1000:1; the addition amount of the inorganic component is 5% of the mass of the olefin polymer monomer, and the addition amount of the organic macromolecular additive is 10% of the mass of the olefin polymer monomer; the inorganic component is iron-containing kaolin, and the organic high The molecular auxiliary is a silane-containing coupling agent; the reaction temperature of vacuum infusion is 35°C. The amount of carbon fiber cloth added is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com