Preparation method and application of nitrogen-sulfur co-doped graphene for persulfate activation

A technology of activating persulfate and nitrogen-sulfur co-doping, which is applied in the field of graphene to achieve the effect of large specific surface area, less dosage and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

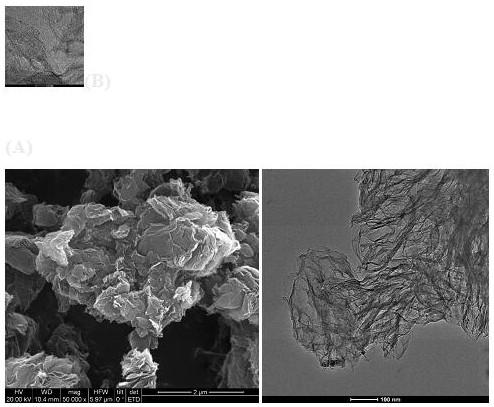

[0037] Take a certain amount of commercial graphene (IrGO) and thiourea, mix them evenly, and put them into nitrogen gas (N 2 ) Calcined at 350°C in a tube furnace for 30min. The calcination time was 60min at different times, and the heating rate was chosen to be 10°C / min for multiple tests. After cooling to room temperature under a nitrogen atmosphere, the obtained samples were washed three times with ultrapure water and then three times with ethanol. The vacuum drying temperature was 60°C and the drying time was 12h, and finally the test sample IrGO-NS was obtained.

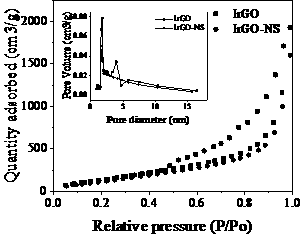

[0038] For the test samples, Quanta400FEG scanning electron microscope (SEM) (FEI, USA) and JEM-2100F high-resolution transmission electron microscope (HRTEM) (JEOL, Japan) were used for morphological analysis of the samples. Surface elemental composition was analyzed using an ESCALAB250XIX-ray photoelectron spectroscopy (XPS) system (ThermoFisher Scientific, USA). Nitrogen adsorption–desorption isotherms, s...

Embodiment 2

[0045]The test sample prepared in Example 1 was taken for the experiment of degrading the preservative methylparaben (MP). In the 15 mg / LMP solution, 20 mg / L IrGO-NS and 307 mg / L PMS were added, and samples were taken at regular intervals, filtered to remove IrGO-NS, and methanol was added to terminate the reaction, and the concentration of MP in the reaction solution was analyzed by HPLC.

[0046] As a comparison, conventional GO and its N-doped samples or classical metal catalysts (nano-Co 3 o 4 and Fe 3 o 4 ) as a catalyst, other conditions are the same as above.

[0047] IrGO-NS was added alone without PMS, and the other conditions were the same as above.

[0048] Add PMS alone, without IrGO-NS, other conditions are the same as above.

[0049] Such as Figure 6 As shown, in the case of less amount of catalyst and oxidant, conventional GO and its N-doped samples or classical metal catalyst (nano-Co 3 o 4 and Fe 3 o 4 ) cannot effectively activate PMS to remove MP....

Embodiment 3

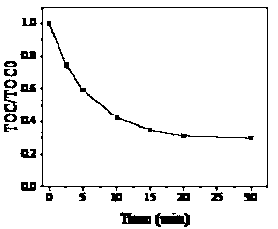

[0051] The test sample prepared in Example 1 was taken to conduct the mineralization effect test of the preservative methylparaben (MP). In the 15 mg / L MP solution, 20 mg / L IrGO-NS and 307 mg / L PMS were added, and samples were taken at regular intervals, filtered to remove IrGO-NS, and the TOC change of the reaction solution was analyzed. Such as Figure 7 It can be seen that 70% TOC can be removed after 30 min. It can be seen that under the experimental conditions, IrGO-NS and PMS have a good mineralization effect on MP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com