Method for using Pickering emulsion method for producing GelMA macropore hydrogel and application

A technology of hydrogel and emulsion method, applied in pharmaceutical formulation, medical science, prosthesis, etc., can solve the problems of unfavorable material biocompatibility, increase toxicity, unable to form connected pores, etc., to promote proliferation and osteogenic differentiation ability, enhanced delivery, good biocompatibility, and effects of degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

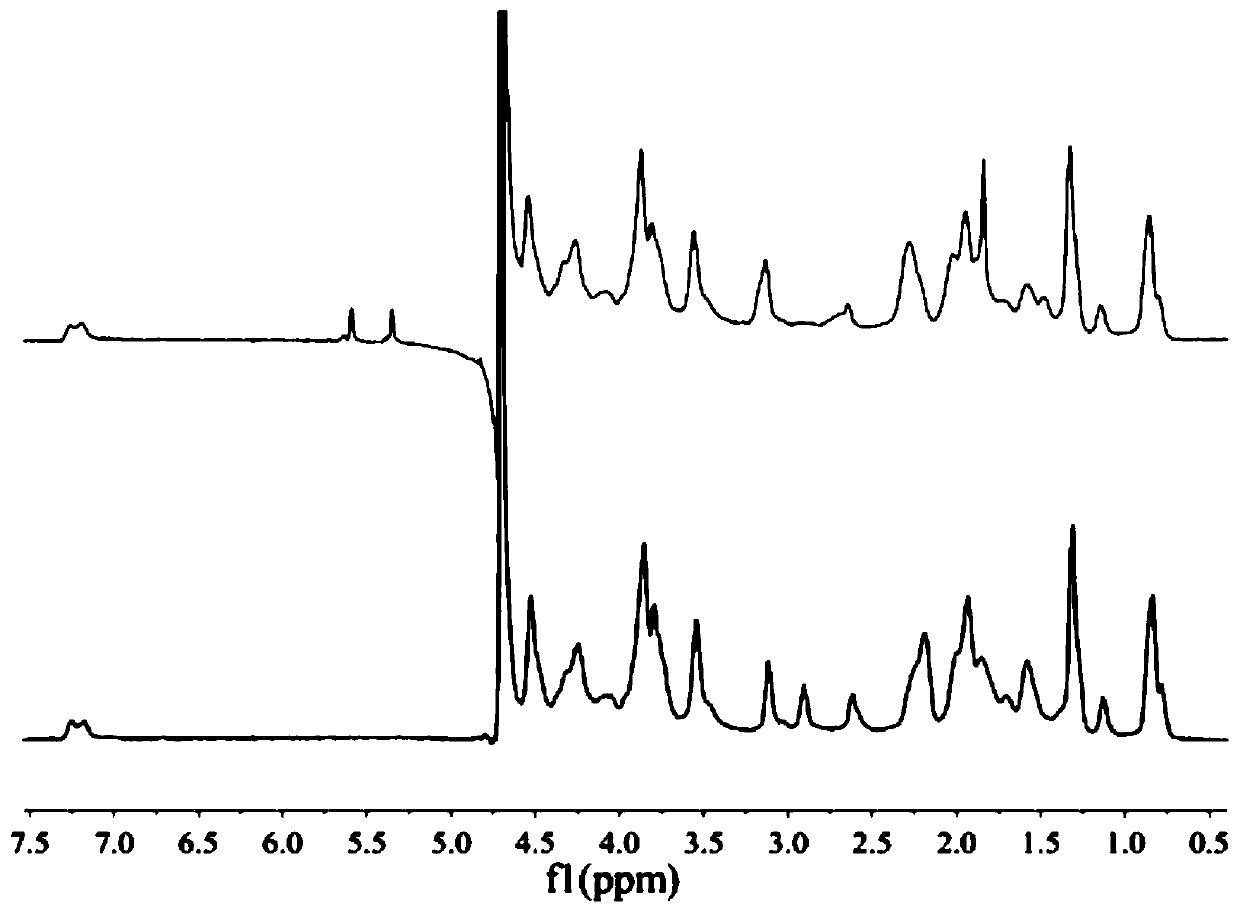

[0035] Embodiment 1 (modification and characterization of gelatin)

[0036] 1. Modification of gelatin

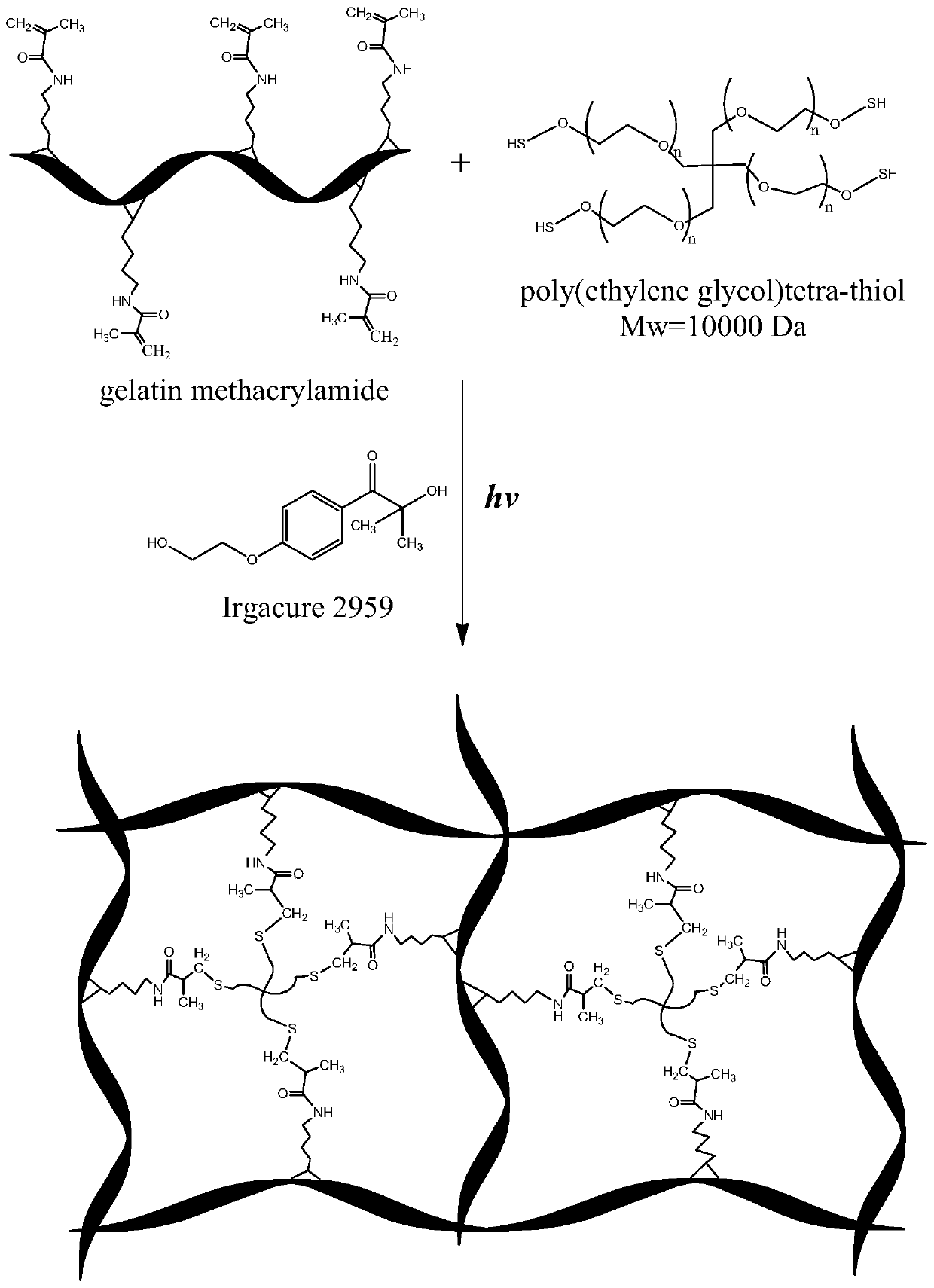

[0037] GelMA is obtained by modifying gelatin with methacrylic anhydride. By grafting methacrylic anhydride to the gelatin molecular chain, a highly reactive carbon-carbon double bond is introduced into the gelatin molecular chain, which is beneficial to the four-armed PEG. The sulfhydryl groups on the -4SH molecule undergo a thiol-ene click reaction, and are cross-linked into a gel network under UV light. The gelation mechanism of GelMA macroporous hydrogel is shown in figure 1 .

[0038] Dissolve 5g of gelatin in 50mL of PBS (1×) buffer, in a 60°C water bath, stir until completely dissolved. 10 mL of methacrylic anhydride was dropped into the stirring gelatin solution at a rate of 0.5 mL / min, and reacted for 3 hours in a water bath at 50°C. After cooling slightly, the reaction was diluted to 5 times with 40°C PBS (1×) to terminate the reaction. Dialyze with a 12-14kD...

Embodiment 2

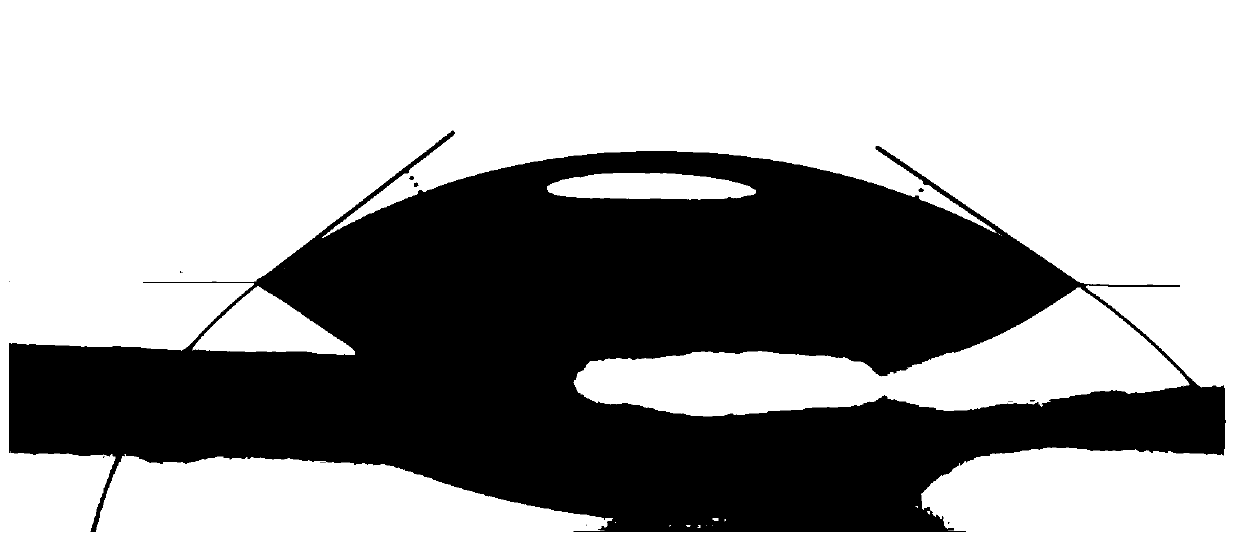

[0042] Embodiment 2 (contact angle test of MgO nanoparticles)

[0043] Pickering emulsion is an emulsion obtained by using ultrafine solid particles as an emulsifier. Assuming that the solid particles are spherical, the state of the particles in the oil-water phase, and the surface energy between particles-water, particle-oil, and water-oil are crucial to the type of emulsion formation. If the contact angle between the particle and the water phase θ90°, that is, the wettability of the particles and the oil phase is better, and the system is easy to form a water-in-oil (W / O) emulsion. Therefore, we can roughly judge the type of emulsion by the contact angle between the particles and water, and the hydrophilicity and hydrophobicity of the particles must be moderate, and stable emulsions cannot be obtained if they are too hydrophilic or too hydrophobic.

[0044] Disperse the MgO powder in absolute ethanol, ultrasonically for 30 minutes, fully disperse evenly, and then drop it on a...

Embodiment 3

[0046] Embodiment 3 (compression performance test of GelMA macroporous hydrogel scaffold)

[0047] Dissolve 0.05g GelMA in 0.25mL PBS solution (1×), stir until fully dissolved. Mix 0.25mL 0.2g / mL PEG-4SH (10,000 molecular weight) solution with GelMA solution evenly. Add 1.5mg of nano-MgO into 0.5mL of dodecane, and sonicate for 15min. Mix GelMA, PEG-4SH, dodecane, and I 2959 photoinitiator, and stir for 60s at 16,000 rpm with a homogenizer. Transfer the emulsion to a PDMS mold with a thickness of 5 mm and a diameter of 1 cm, and UV light for 60 seconds on the front and back sides. Finally, a GelMA macroporous hydrogel scaffold for compressive modulus testing was prepared. The compression curves of hydrogel scaffolds with 0.3wt% and 0.5wt% MgO content are shown in Figure 4 .

[0048] The 0.5wt% group has a higher MgO content and a smaller emulsion droplet size, so the pore size of the hydrogel is smaller, so the sample with a higher MgO content has a higher compressive mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com