Coal ash-iron tailing based geopolymer fiber reinforced material and preparation method thereof

A fiber-reinforced material and geopolymer technology, applied in the field of new green inorganic gel materials, can solve the problems of unfavorable polycondensation reaction, reduction of gel phase, low activity, etc., and achieve the advantages of easy availability of raw materials, low cost and high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

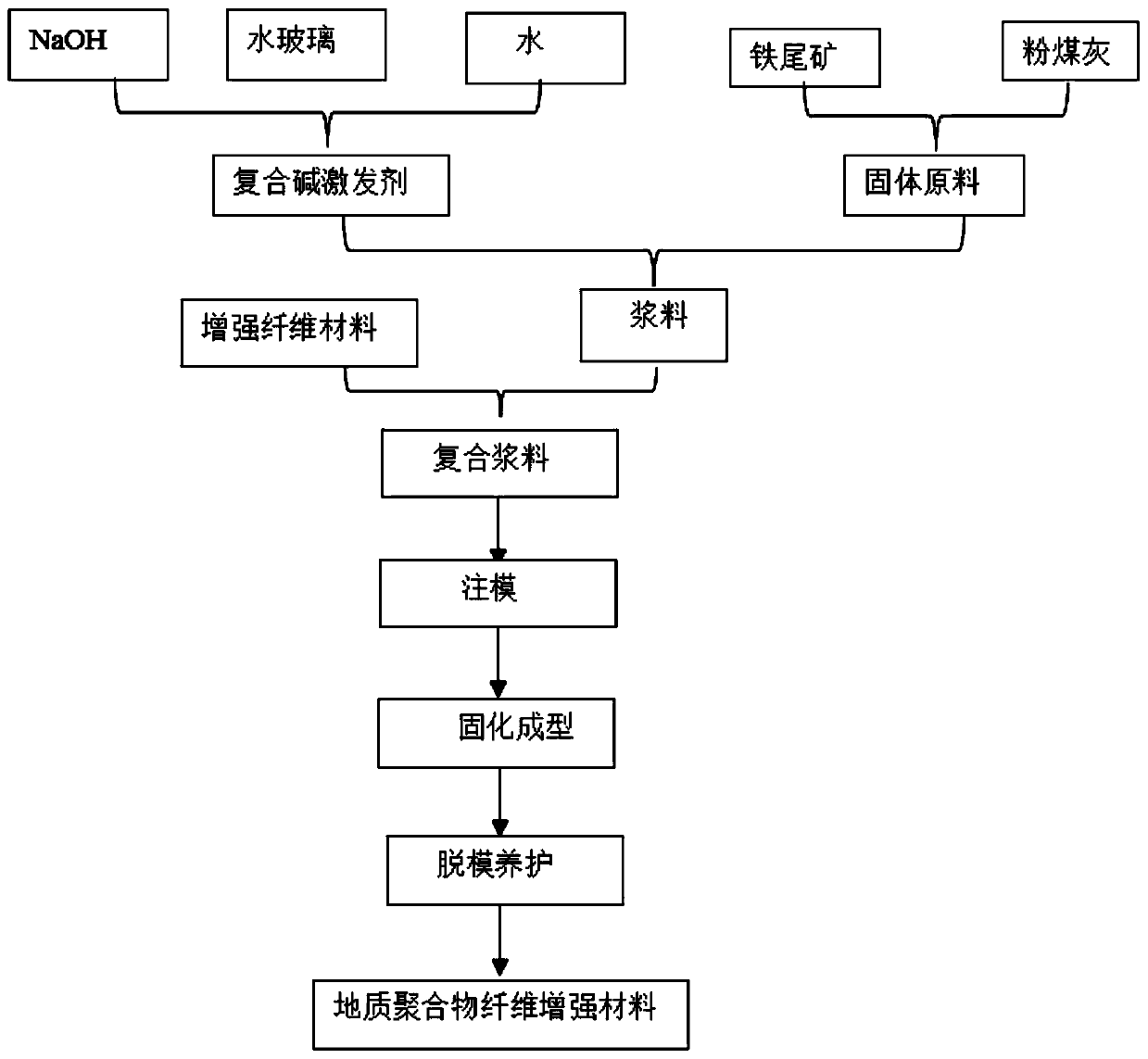

[0058] This embodiment provides a preparation method based on fly ash-iron tailings geopolymer basalt fiber reinforced material, including:

[0059] (1) Preparation of solid raw materials: iron tailings were taken, dried in a drying oven at 105°C for 3 hours, dehydrated, ground, sieved with a 150-mesh sieve, and particles with a particle size of ≤50 μm accounted for more than 98%. Take secondary fly ash with a particle size of ≤200 μm, calcinate in a resistance furnace at 800°C for 2 hours, and cool to obtain fly ash for use. According to SiO 2 / Al 2 o 3 The molar ratio is 2.8, take 2197.12g of iron tailings, 2602.88g of fly ash, and a total mass of 4800g, and mix them uniformly to obtain solid raw materials. After mixing evenly, add 4-8mm basalt chopped fibers with a volume of 0.5% of the slurry and stir evenly to obtain a composite slurry.

[0060] (2) Preparation of composite base activator: according to SiO 2 / Na 2 The mol ratio of O is the proportioning of 1.6, gets...

Embodiment 2

[0066] This embodiment provides a preparation method based on fly ash-iron tailings geopolymer basalt fiber reinforced material, including:

[0067] (1) Preparation of solid raw materials: iron tailings were taken, dried in a drying oven at 115°C for 2 hours, dehydrated, ground, and sieved with a 100-mesh sieve. Particles with a particle size of ≤50 μm accounted for more than 74%. Take secondary fly ash with particle size ≤ 200μm, according to SiO 2 / Al 2 o 3 With a molar ratio of 3.2, take 2856.96g of iron tailings, 1943.04g of fly ash, and a total mass of 4800g, and mix them uniformly to obtain solid raw materials.

[0068] (2) Preparation of composite base activator: according to SiO 2 / Na 2 The mol ratio of O is the proportioning of 1.6, gets powdery sodium hydroxide 313.32g, water glass 2346.56g, mixes. According to H 2 O / Na 2 O molar ratio is that the proportioning of 8 adds 275.2g deionized water and stirs and obtains composite alkali activator.

[0069] (3) Slu...

Embodiment 3

[0074] This embodiment provides a preparation method based on fly ash-iron tailings geopolymer basalt fiber reinforced material, including:

[0075] (1) Preparation of solid raw materials: iron tailings were taken, dried in a drying furnace at 110° C. for 2 hours, dehydrated, ground, sieved with a 150-mesh sieve, and particles with a particle size of ≤50 μm accounted for more than 98%. Take secondary fly ash with particle size ≤200μm. According to SiO 2 / Al 2 o 3 When the molar ratio is 3.0, take 2549.44g of iron tailings, 2250.56g of fly ash, and a total mass of 4800g, and mix them uniformly to obtain solid raw materials.

[0076] (2) Preparation of composite base activator: according to SiO 2 / Na 2 The molar ratio of O is the proportioning of 1.6, gets powdery sodium hydroxide 417.92g, water glass 3132.16g, mixes. According to H 2 O / Na 2 O molar ratio is that the proportioning of 11 adds 1048.64g deionized water, stirs and obtains composite alkali activator.

[0077...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com