Cyclodextrin-metal organic framework material composite microspheres and preparation method thereof

A metal-organic framework and composite microsphere technology, which is applied in the direction of microsphere preparation, microcapsule preparation, organic active ingredients, etc., can solve the problems of cumbersome steps, long time-consuming, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a preferred embodiment of the present invention, it also relates to the preparation method of the above-mentioned cyclodextrin-metal organic framework material composite microspheres, comprising the following steps:

[0041] (A) providing a cyclodextrin-metal organic framework material, loading drugs on the cyclodextrin-metal organic framework material to obtain a drug-loaded cyclodextrin-metal organic framework material;

[0042] (B) ethyl cellulose is dissolved in an organic solvent to obtain an ethyl cellulose solution;

[0043] (C) mixing and dispersing the drug-loaded cyclodextrin-metal organic framework material and ethyl cellulose solution evenly to obtain a mixed solution;

[0044] (D) uniformly supply the mixed solution to the nozzle of the drug ultrafine particle preparation system through a peristaltic pump, adjust the rotation speed of the high-speed disc and the liquid supply speed, and the liquid flow is sheared and dispersed instantaneously to prepare ...

Embodiment 1

[0052] Preparation of CD-MOFs

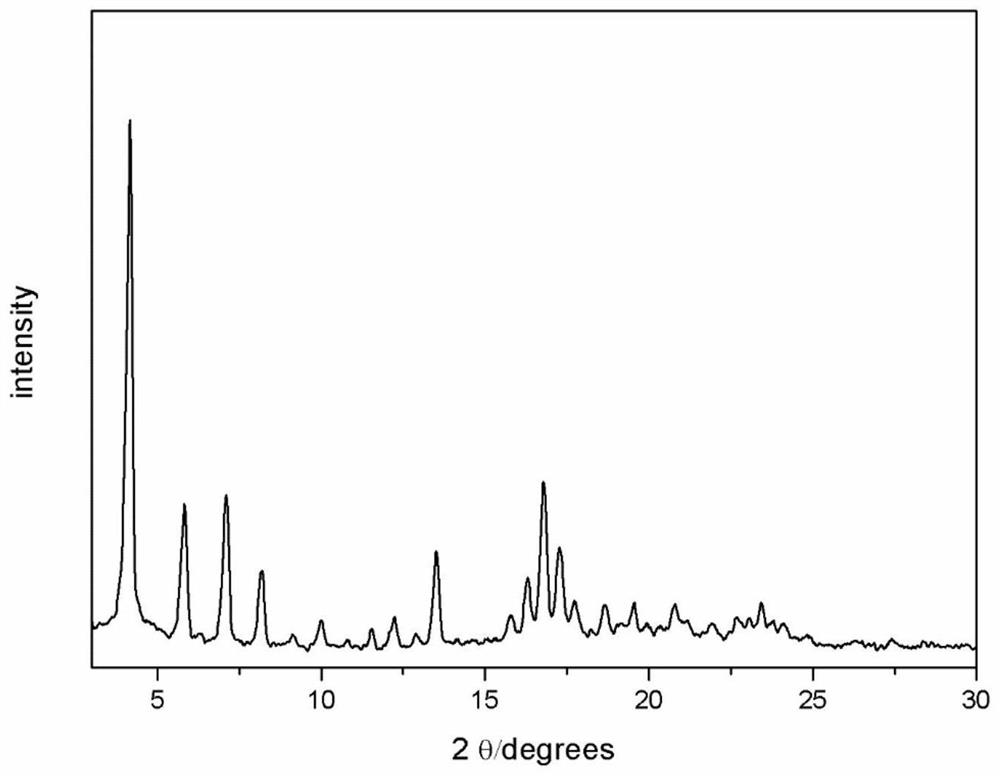

[0053] Dissolve γ-cyclodextrin and potassium hydroxide in 200mL deionized water, and filter through a 0.8μm filter membrane after the two are completely dissolved, then add 120mL methanol to the filtrate, transfer to a 50°C water bath and heat for 0.5h. Then add 300mL methanol and CTAB (8mg·mL -1 ), CTAB was completely dissolved and left to stand at room temperature for 2 h. Finally, the CD-MOFs were collected by centrifugation, washed with isopropanol, and the solid was vacuum-dried overnight. Please participate in the PXRD pattern of prepared CD-MOFs figure 1 .

Embodiment 2

[0055] Preparation of CD-MOFs loaded with ketoprofen

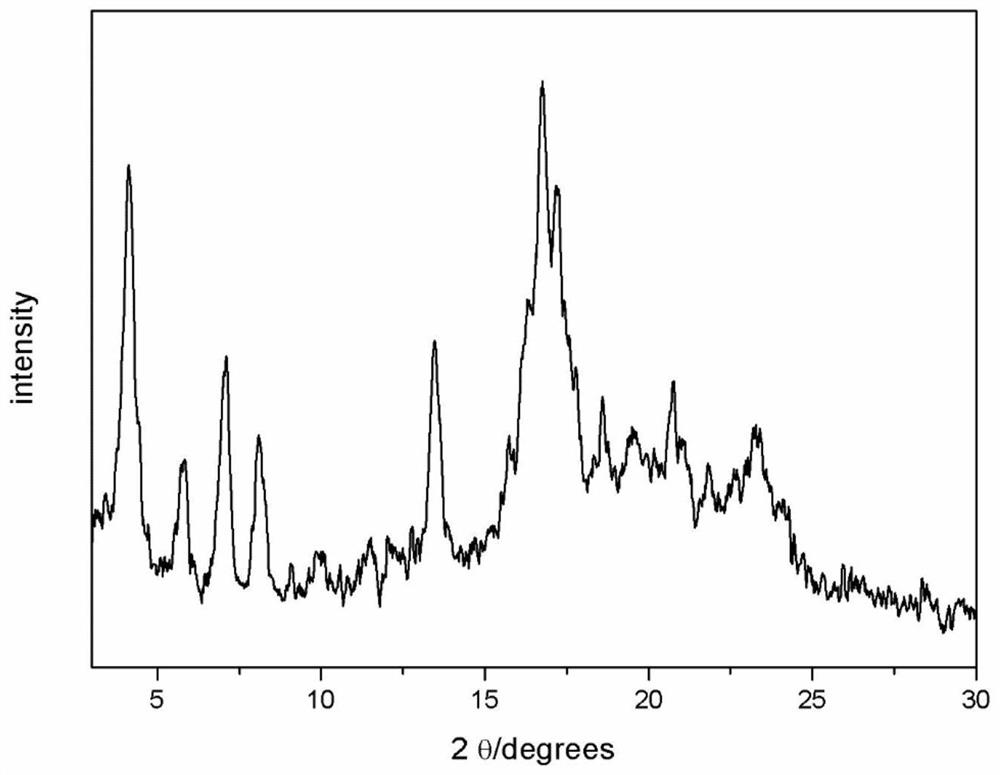

[0056] 4g ketoprofen (KET) was dissolved in 100mL of acetone, the concentration was 40mg·mL -1 , then added 4 g of CD-MOFs, stirred for 24 h, and then washed twice with a KET-dissolving solvent to remove excess drug. The solid was vacuum-dried overnight to obtain ketoprofen-loaded CD-MOFs (KET-CD-MOFs). The PXRD pattern of the prepared drug-loaded CD-MOFs please participate in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com