Waste residue grinding, leaching, detoxifying and degassing integrated treatment system and treatment method thereof

A treatment system, grinding and leaching technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the impact of environmental, human health waste residue recycling and comprehensive utilization of resources, drinking water sources and residents' lives Threats, detrimental to the personal safety of the surrounding people, etc., to achieve the effects of eliminating toxic hazards of waste residue, saving reaction time, and simple and unique equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

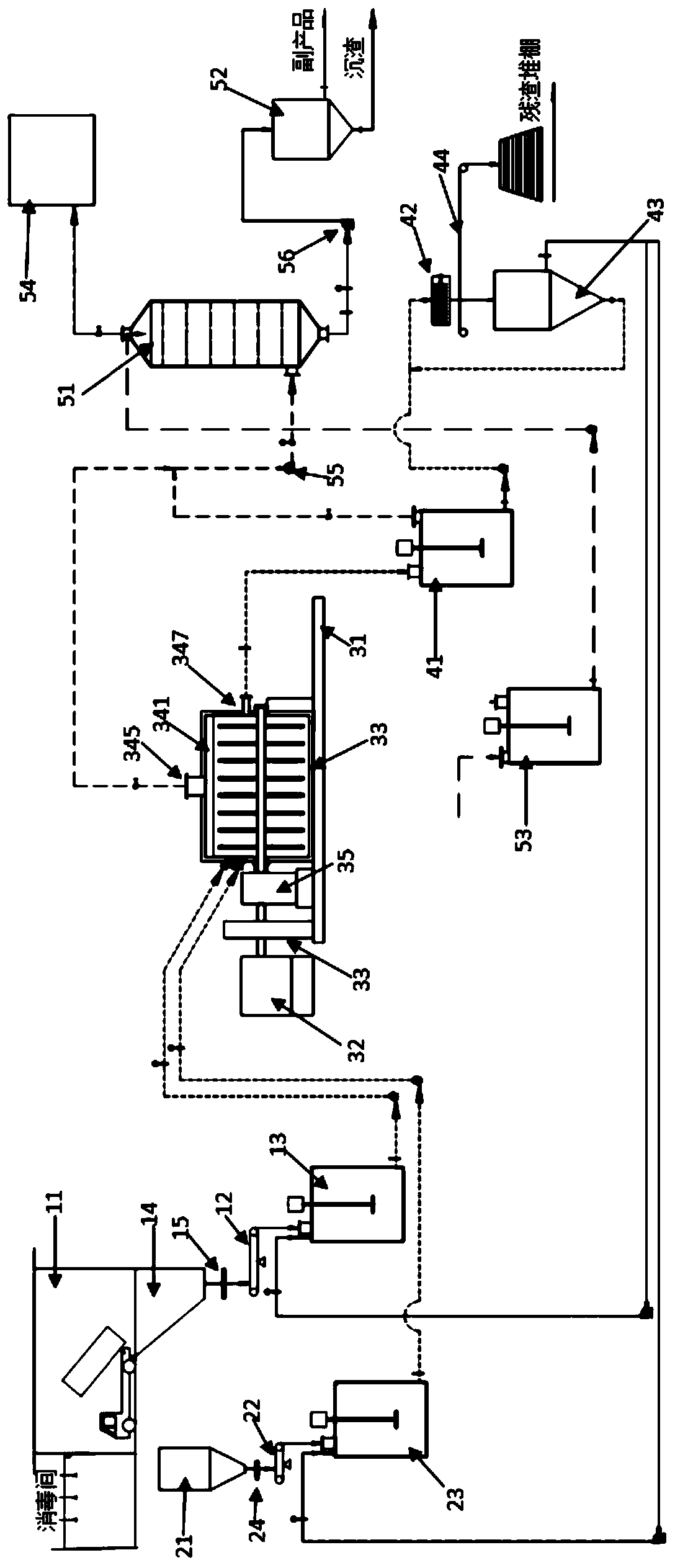

[0060] Embodiment 1: The integrated treatment method of ammonium alum slag grinding, detoxification and degassing

[0061] Ammonium alum slag is smelting waste, including types such as aluminum ammonium alum slag and ferric ammonium alum slag. Its common feature is that it contains ammonium sulfate components. The ammonium in the waste residue is converted into ammonia gas for removal, thereby eliminating the risk of environmental pollution. The present embodiment is combined with aluminum ammonium alum slag as example Figure 4 Be explained.

[0062] S1. Pretreatment of aluminum ammonium alum slag: transport the aluminum ammonium alum slag to the unloading pit of the unloading room by a special vehicle, and send it to the first mixing tank after being measured by the first feeder, and add 1-3 times according to the mass ratio Stir the water evenly to prepare the aluminum ammonium alum slag slurry;

[0063] S2. Auxiliary deployment: The first auxiliary agent is calcium carb...

Embodiment 2

[0068] Embodiment 2: Barium slag grinding immersion detoxification and degassing integrated treatment method

[0069] The barium slag contains soluble barium sulfide, and the present invention utilizes the integrated processing system of grinding, leaching, detoxification and degassing to process the barium slag, and can convert the barium sulfide in the barium slag into H 2 S removal, thereby eliminating the risk of environmental pollution. This embodiment is combined with barium slag treatment as an example Figure 5 Be explained.

[0070] S1. Barium slag pretreatment: transport the barium slag to the unloading pit of the unloading room by a special vehicle, measure it through the first feeder and send it to the first mixing tank, add 1-3 times the water according to the mass ratio and stir evenly, Prepare barium slag slurry;

[0071] S2. Auxiliary deployment: the first auxiliary agent uses 20% dilute sulfuric acid, and the sulfuric acid solution is transported to the auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com