Packaging adhesive for perovskite and application method

An application method and encapsulation adhesive technology, which can be applied in adhesive types, photovoltaic power generation, electrical components, etc., can solve perovskite damage, photoelectric performance degradation, narrow temperature application range below 20°C or above 40°C, etc. problems, to avoid damage, increase device stability, and prolong device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

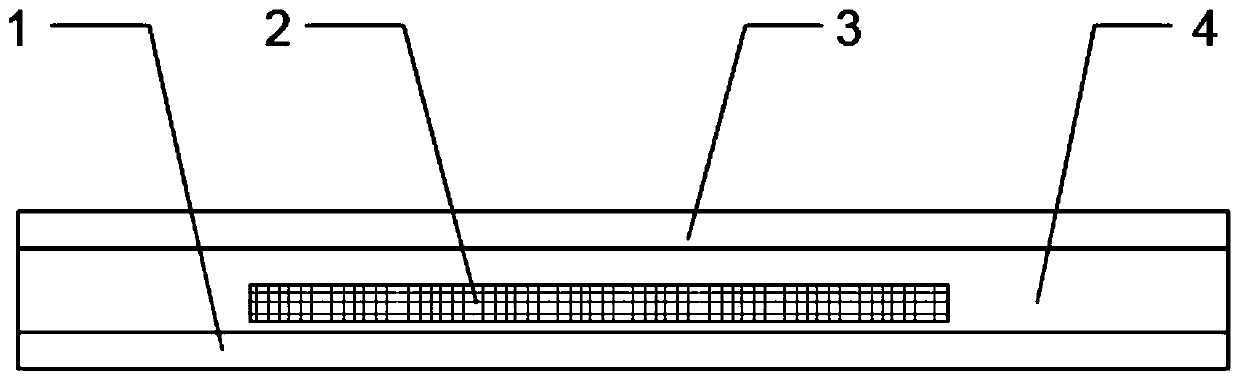

[0046] The polystyrene (PS) plastic cover is a polymer encapsulant formed by mixing polystyrene and cyclohexane. It is suitable for organic-inorganic hybrid perovskite CH with mica crystals as the substrate of perovskite devices. 3 NH 3 PbBr 3 Encapsulate.

[0047] Step 1. Take 10ml cyclohexane solution (purity> 99%) into a 50ml beaker, weigh 1g of polystyrene into cyclohexane, stir the mixed solution at room temperature for 30 minutes, so that the polystyrene is fully dissolved in cyclohexane to form a polymer encapsulation glue

[0048] Step 2. Cut the polystyrene plastic bottom plate to 25*25*0.2mm and the upper cover plate to 20*20*0.2mm, and clean it. Use a micropipette to extract 4ml of polymer encapsulated glue and drop it on a 25*25*0.2mm polystyrene plastic bottom plate, smear the entire surface evenly, and it will contain organic-inorganic hybrid perovskite CH 3 NH 3 PbBr 3 The lower surface of the mica substrate with an area of 12*12*0.1mm is covered on the bottom plate...

Embodiment 2

[0052] The polystyrene (PS) plastic cover is a polymer encapsulant formed by mixing polystyrene and cyclohexane. It is suitable for organic-inorganic hybrid perovskite CH with mica crystals as the substrate of perovskite devices. 3 NH 3 PbCl 3 Encapsulate.

[0053] Step 1. Take 10ml cyclohexane solution (purity> 99%) into a 50ml beaker, weigh 1g of polystyrene and add it to cyclohexane, stir the mixed solution at room temperature for half an hour, so that the polystyrene is fully dissolved in cyclohexane to form a polymer encapsulant

[0054] Step 2. Cut the polystyrene plastic bottom plate to 25*25*0.2mm and the upper cover plate to 20*20*0.2mm, and clean it. Use a micropipette to extract 4ml of polymer encapsulated glue and drop it on a 25*25*0.2mm polystyrene plastic bottom plate, smear the entire surface evenly, and it will contain organic-inorganic hybrid perovskite CH 3 NH 3 PbCl 3 The lower surface of a mica substrate with a surface area of 12*12*0.1mm is covered on the bot...

Embodiment 3

[0057] The polystyrene (PS) plastic cover is a polymer encapsulant formed by mixing polystyrene and cyclohexane. It is suitable for organic-inorganic hybrid perovskite CH with mica crystals as the substrate of perovskite devices. 3 NH 3 PbI 3 Encapsulate.

[0058] Step 1. Take 10ml cyclohexane solution (purity> 99%) into a 50ml beaker, weigh 1g of polystyrene and add it to cyclohexane, stir the mixed solution at room temperature for half an hour, so that the polystyrene is fully dissolved in cyclohexane to form a polymer encapsulant

[0059] Step 2. Cut the polystyrene plastic bottom plate to 25*25*0.2mm and the upper cover plate to 20*20*0.2mm, and clean it. Use a micropipette to extract 2ml polymer encapsulated glue droplets on a 25*25*0.2mm polystyrene plastic bottom plate, and smear the entire surface evenly. The area containing the organic-inorganic hybrid perovskite CH3NH3PbI3 will be 12*12* The lower surface of the 0.1mm mica substrate is covered on the bottom plate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com