Preparation method and application of silicon-titanium composite homogeneous catalyst for polyester synthesis

A homogeneous catalyst and co-catalyst technology, applied in the field of polyester synthesis, can solve problems such as unfavorable environmental protection and sustainable development, many side reactions, and restrict development, achieve good industrial application prospects and values, and improve activity and stability , the effect of increasing the polymerization reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of silicon-titanium composite homogeneous catalyst:

[0034] 1) Dissolve the titanium compound and silicon compound in a mixed solvent composed of ethylene glycol and another alcoholic solvent, add the first co-catalyst and the second co-catalyst, and distill at 80-120°C for 2-6 hours under normal pressure , remove low boiling point components; the first co-catalyst is acetate; the second co-catalyst is alkylbenzenesulfonate compound;

[0035] 2) adding the first complexing agent and the second complexing agent, continuing atmospheric distillation at 80-120° C. for 2-6 hours, removing low-boiling components, and obtaining a silicon-titanium composite homogeneous catalyst; the first complexing agent At least one selected from hydroxycarboxylic acids, pyrrolidones and lactams; the second complexing agent is selected from at least one of phosphoric acid, phosphorous acid, alkylphosphonic acid, phosphonous acid, phosphonous acid and esters thereof A sort of.

...

Embodiment 1

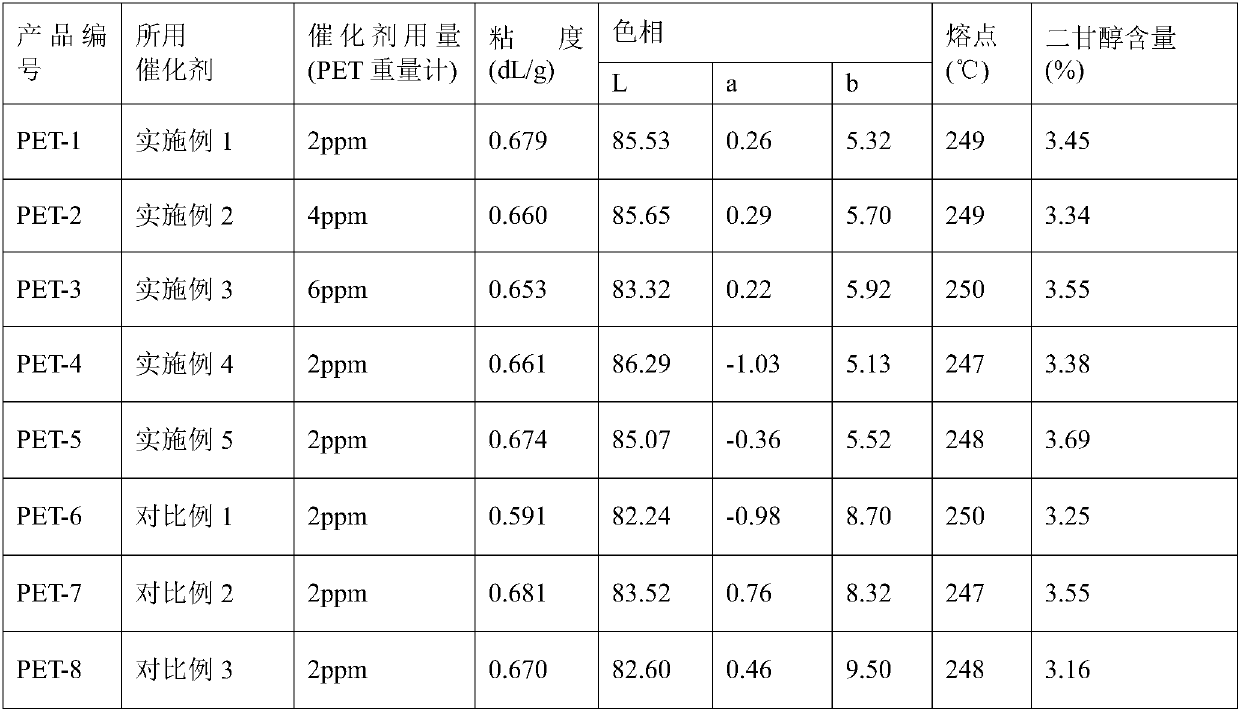

[0051] Add 37.2g (0.6mol) of ethylene glycol to a 250ml flask equipped with a magnetic stirring and condensing device, and dissolve 2.4608g (0.03mol) of sodium acetate and 1.0454g (0.003mol) of dodecylbenzenesulfonic acid into it Sodium, then add 10.2g (0.03mol) n-butyl titanate, 25.0g (0.12mol) ethyl orthosilicate and 13.8g (0.3mol) ethanol to the solution, react at 85°C for 2.5h, and distill off small molecules Finally, add 6.3028g (0.03mol) of citric acid monohydrate and 4.7676g (0.03mol) of phenylphosphonic acid to the reaction system, react at 85°C for 2.5h, and distill off small molecules to obtain titanium-containing 1.4001% liquid catalyst. Table 1 shows the performance results of polyester chip products prepared by using this catalyst through a conventional polyester process.

Embodiment 2

[0053] Add 37.2g (0.6mol) of ethylene glycol to a 250ml flask equipped with a magnetic stirring and condensing device, and dissolve 6.4342g (0.03mol) of magnesium acetate tetrahydrate and 0.5227g (0.0015mol) of dodecylbenzene into it Sodium sulfonate, then add 10.2g (0.03mol) n-butyl titanate, 25.0g (0.12mol) ethyl orthosilicate and 13.8g (0.3mol) ethanol to the solution, react at 85°C for 2.5h, and distill off After the small molecules, add 2.7042g (0.03mol) lactic acid and 4.7676g (0.03mol) phenyl phosphoric acid to the reaction system, react at 85°C for 2.5h, and distill off the small molecules to obtain a liquid containing 1.4526% titanium catalyst. Table 1 shows the performance results of polyester chip products prepared by using this catalyst through a conventional polyester process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com