Microbial strain BF-1801 for efficiently degrading cellulose

A technology of microbial strains and strains, applied in the field of microorganisms, can solve environmental pollution and other problems, and achieve the effect of broad application prospects and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the culture activation of bacterial strain BF-1801

[0017] Strain BF-1801 is derived from bovine rumen, and after selection from bovine rumen, it is cultured and activated using the following fermentation medium and culture conditions.

[0018] Liquid medium (10ml): (1) Basal medium (5ml): every 50mL contains NaHCO3 0.5g, peptone 0.1g, yeast extract powder 0.1g; (2) mineral solution A (1.65mL): every 50mL contains KH 2 PO4 0.15g, (NH 4 ) 2 SO 4 0.15g, NaCl0.3g, CaCl 2 2H 2 O 0.02g, MgSO 4 ·7H 2 O 0.029g; (3) Mineral solution B (1.65mL): every 50mL contains K 2 HPO4·3H 2 O 0.198g; (3) cysteine hydrochloride 0.015g, glucose 0.05g

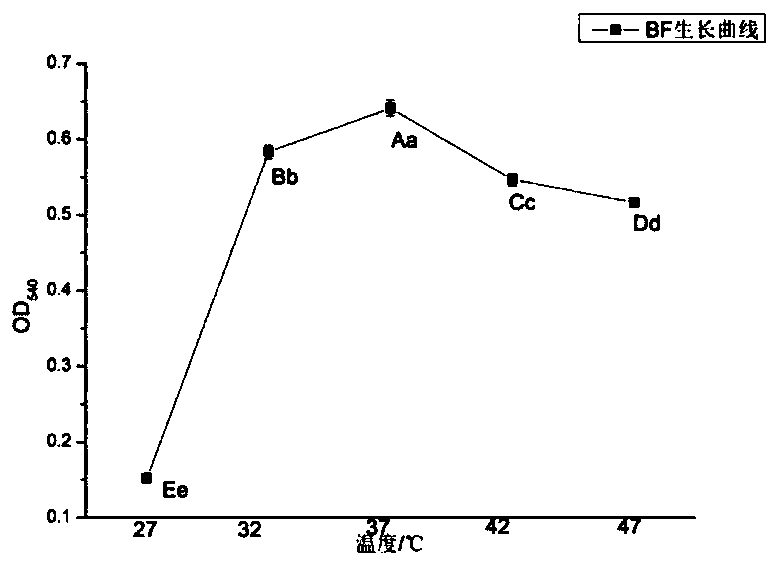

[0019] Inject the preserved strains into the prepared liquid culture medium according to the ratio of 5%. Put into constant temperature shaking incubator, 37 ℃, 180r / min activation culture.

[0020] Solid medium: (1) Basal medium (2.5ml): every 50mL contains NaHCO 3 0.5g, peptone 0.1g, yeast extract powder 0.1g; (...

Embodiment 2

[0024] Embodiment 2: Determination of bacterial strain BF-1801 cellulase activity

[0025] 2.1 Determination method of strain BF-1801β-glucosidase enzyme activity: Take 1.0% crude enzyme solution, add 2.0ml 0.5% salicin solution, bathe in 50℃ water for 10min, add 1mlDNS reagent, fully mix and boil in boiling water bath After cooling for 5 minutes, dilute to 20ml with distilled water, measure the absorbance value OD530 at a wavelength of 530nm with a spectrophotometer, and treat the heat-inactivated crude enzyme solution as a blank in the same way.

[0026] 2.2 Determination of endoglucanase activity of strain BF-1801

[0027] Replace the substrate in 2.1 with carboxymethylcellulose sodium solution, and change the water bath time at 50°C to 30 minutes.

[0028] 2.3 Determination of exoglucanase activity of strain BF-1801

[0029] Replace the substrate in 2.1 with microcrystalline cellulose solution, and change the water bath time at 50°C to 60 minutes.

Embodiment 3

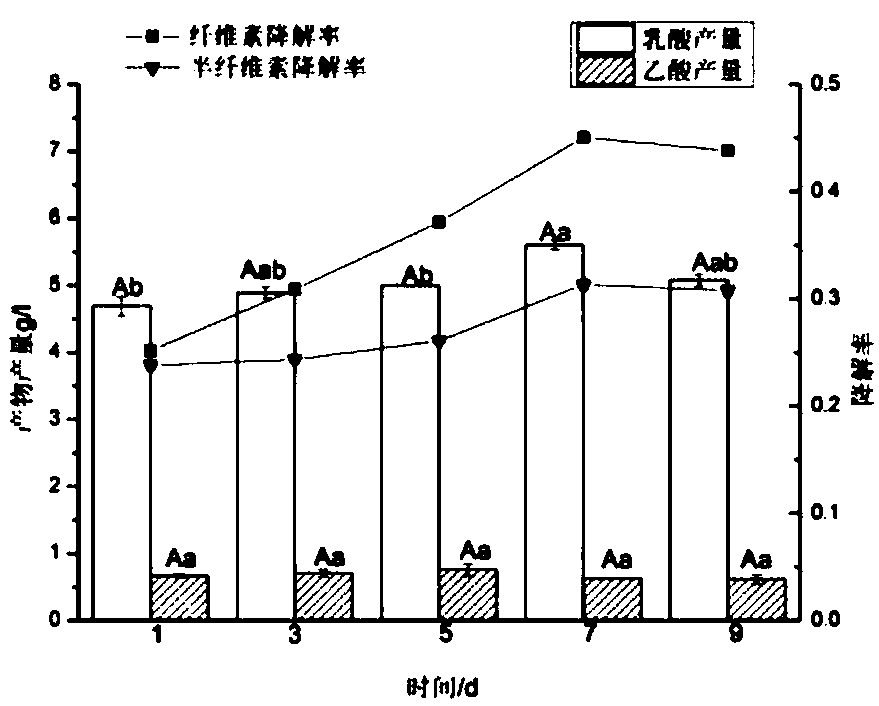

[0030] Example 3: Determination of cellulose degradation rate and hemicellulose degradation rate after fermentation by strain BF-1801 when corn stalks were used as substrate

[0031]Centrifuge the fermented liquid to remove the supernatant, put it into a vacuum dryer, weigh 0.025g of corn stalk sample and add it to the rolling tube after drying, add 250ul of 74% sulfuric acid dropwise, and put it in a water bath at 30°C for 1 hour, stirring continuously during this period. After the reaction, put the roller tube into the prepared ice bath to terminate the reaction, add 7ml of distilled water to each roller tube for dilution, and each group has three parallel samples. Then put the standard sample and the sample together in a high temperature and high pressure sterilizer for hydrolysis. After hydrolysis for 60 minutes, the temperature dropped to 100°C and the samples and standard samples were quickly taken out. After cooling at room temperature, shake the tube well (to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com