Lithium ion battery silicon-based cathode composite binder, preparation method and application thereof

A lithium-ion battery, silicon-based negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low viscosity and unsuitability of polyionic liquids, improve strain performance, improve bonding effect, and improve cycle. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

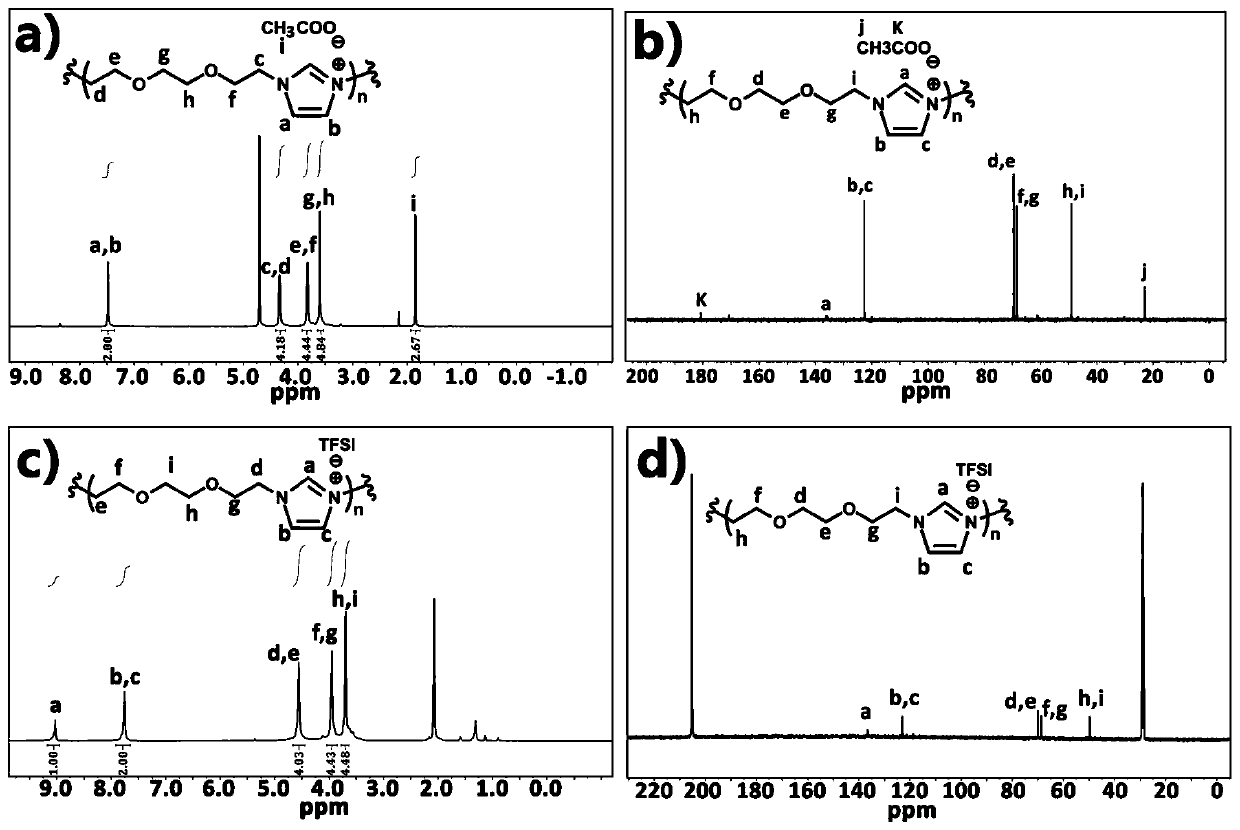

[0032] Embodiment 1 prepares polyionic liquid (PIL / TFSI)

[0033] (1) Acetic acid (4mL) and 2,2'-(ethylenedioxy)bis(ethylamine) (4.89g, 33mmol) were dissolved in deionized water (10mL) to obtain solution A, which was added to a round bottom flask, The round bottom flask was placed in an ice-water bath; then formaldehyde (2.5ml) and glyoxal (4.85ml) were mixed in advance to obtain solution B, and solution B was added dropwise to the above round bottom flask under stirring to obtain solution C;

[0034] (2) After the dropwise addition, transfer the round-bottomed flask to an oil bath, condense and reflux the solution C at 100°C for 1 hour, then cool the entire reaction device at room temperature, and distill under reduced pressure at 80°C to remove excess solvent and reactant, and washed several times with acetone to obtain the product PIL / AcO with a yield of 81%. ;

[0035] (3) Dissolve 2g LiTFSI in 100mL water to obtain a LiTFSI solution, dissolve 1g PIL / AcO prepared in step...

Embodiment 2

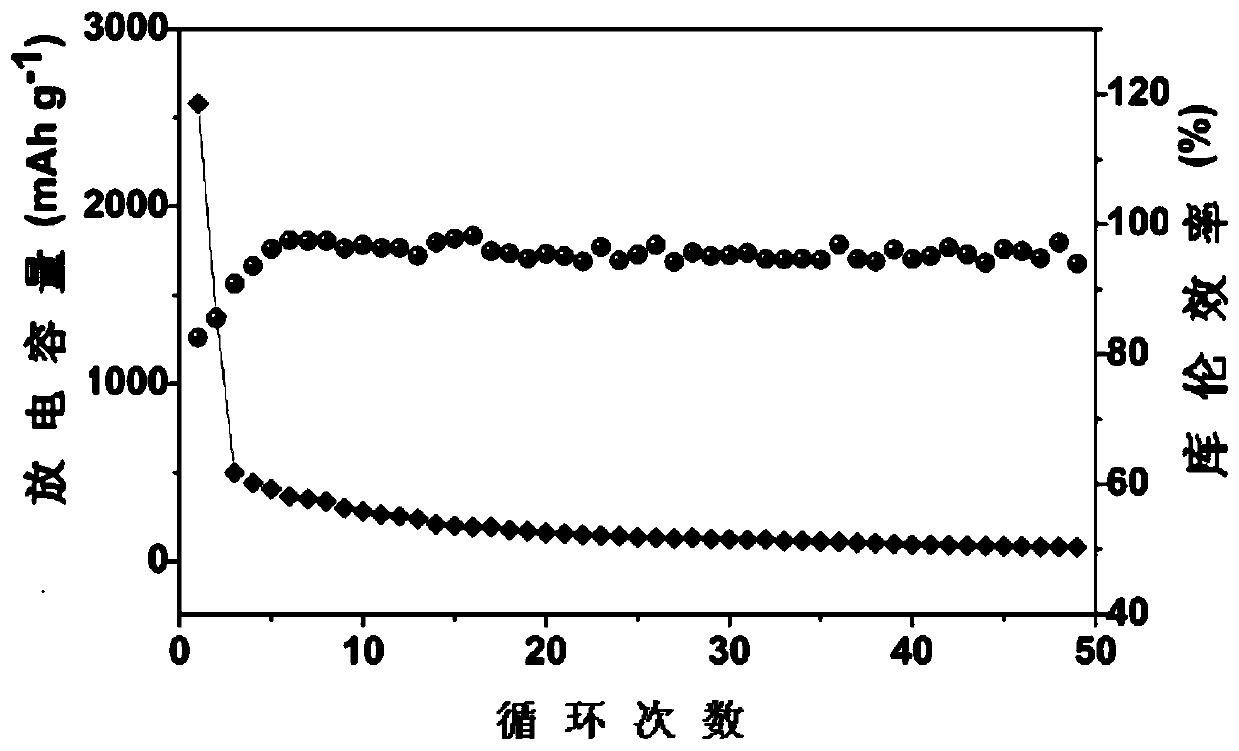

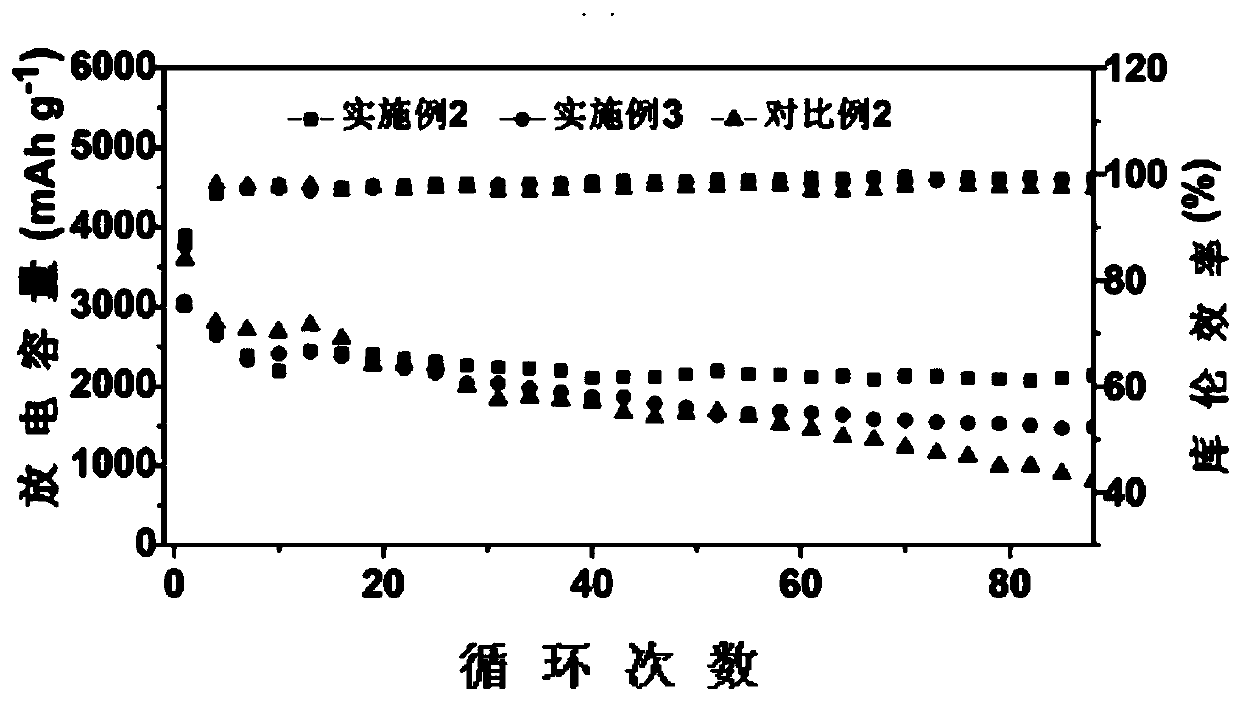

[0044] Example 2 with PAAH 0.8 – Li 0.2 Preparation of Lithium Batteries with Composite Binder of PIL / TFSI

[0045] Weigh PAAH according to the mass ratio of 3:1 0.8 – Li 0.2 (average molecular weight 450,000) and PIL / TFSI, dissolve it in DMSO solvent, heat and evaporate to remove the solvent, and obtain a composite binder; then nano-silicon particles, conductive agent carbon black (Super-P) and composite binder The binder is dispersed in NMP with a mass ratio of 8:1:1, and a uniform slurry is formed by grinding and stirring, and coated on the copper foil. Then place the pole pieces in a drying oven, dry them at 80°C for 36 hours, cut them into circular electrode pieces with a diameter of 1 cm, and store them in a glove box. A lithium sheet was used as the counter electrode to assemble a 2032 button cell. Among them, the electrolyte uses 1M LiPF 6 It is an EC / DMC / DEC solution with a volume ratio of lithium salt of 1:1:1. The assembled battery is left to stand for 12 hour...

Embodiment 3

[0046] Example 3 with PAAH 0.8 – Li 0.2 Preparation of Lithium Batteries with Composite Binder of PIL / TFSI

[0047] Weigh PAAH according to the mass ratio of 2:1 0.8 – Li 0.2 (average molecular weight 450,000) and PIL / TFSI, dissolve it in NMP solvent, heat and evaporate to remove the solvent, and obtain a composite binder; then nano-silicon particles, conductive agent carbon black (Super-P) and composite bond The agent is dispersed in NMP with a mass ratio of 8:1:1, and a uniform slurry is formed by grinding and stirring, and coated on copper foil. Then place the pole piece in a drying oven, dry it at 80°C for 36h, then cut it into a circular electrode piece with a diameter of 1cm, and store it in a glove box. A lithium sheet was used as the counter electrode to assemble a 2032 button cell. Among them, the electrolyte uses 1M LiPF 6 It is an EC / DMC / DEC solution with a volume ratio of lithium salt of 1:1:1. The assembled battery is left to stand for 12 hours, and the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com