Branched polyether monomer for polycarboxylate superplasticizer and synthesis method of branched polyether monomer

A technology of branched polyether and polycarboxylic acid series, which is applied in the field of branched polyether monomers for polycarboxylate water reducers and its synthesis, can solve the problem that the performance cannot meet the needs of changes in concrete raw materials, and there is no Improvement, cost increase and other problems, to achieve the effect of improving bleeding and segregation phenomenon, improving cost performance and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

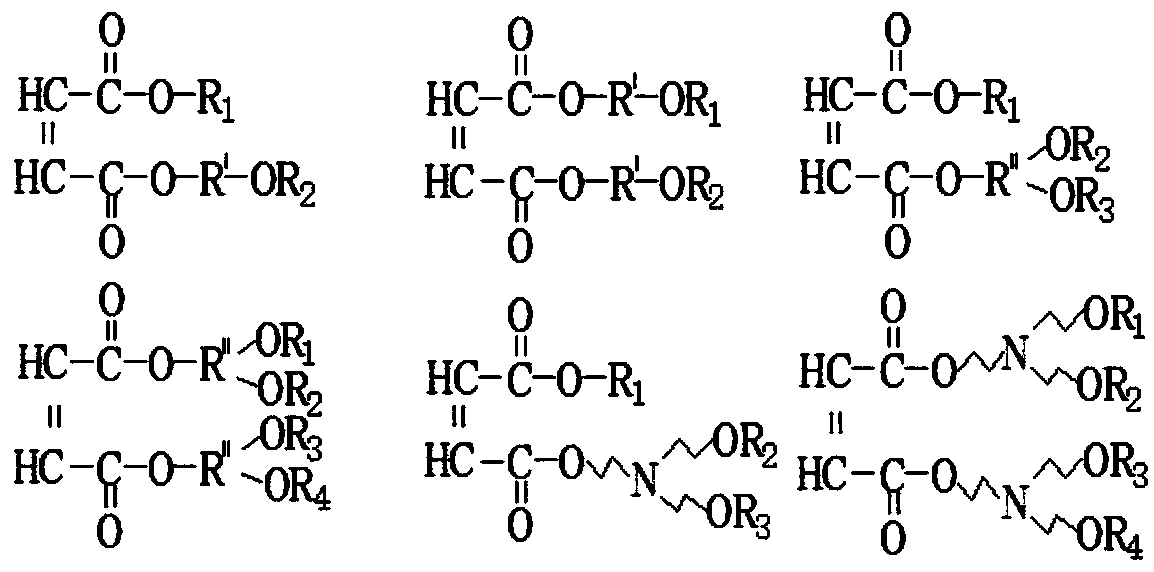

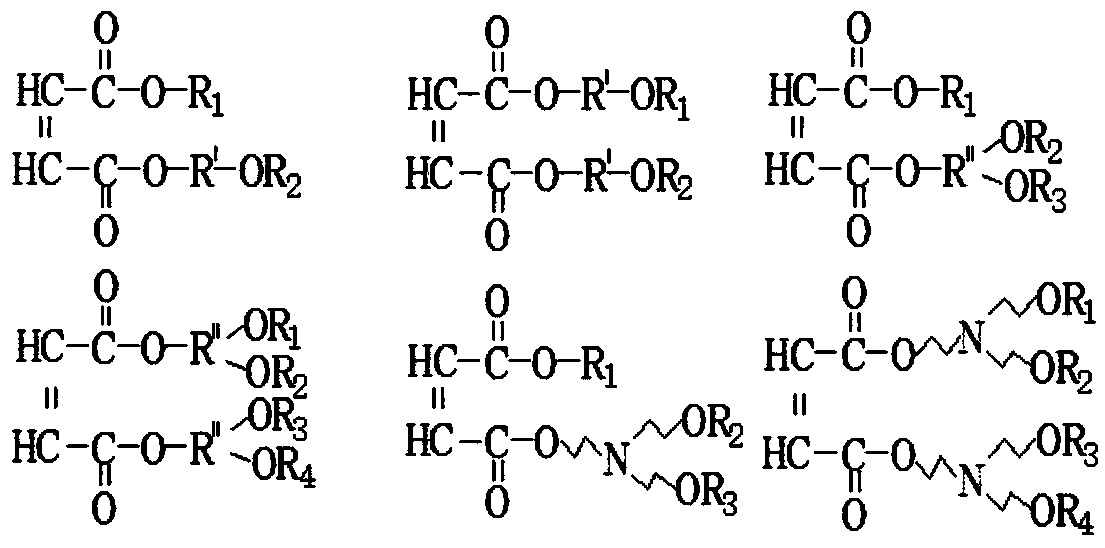

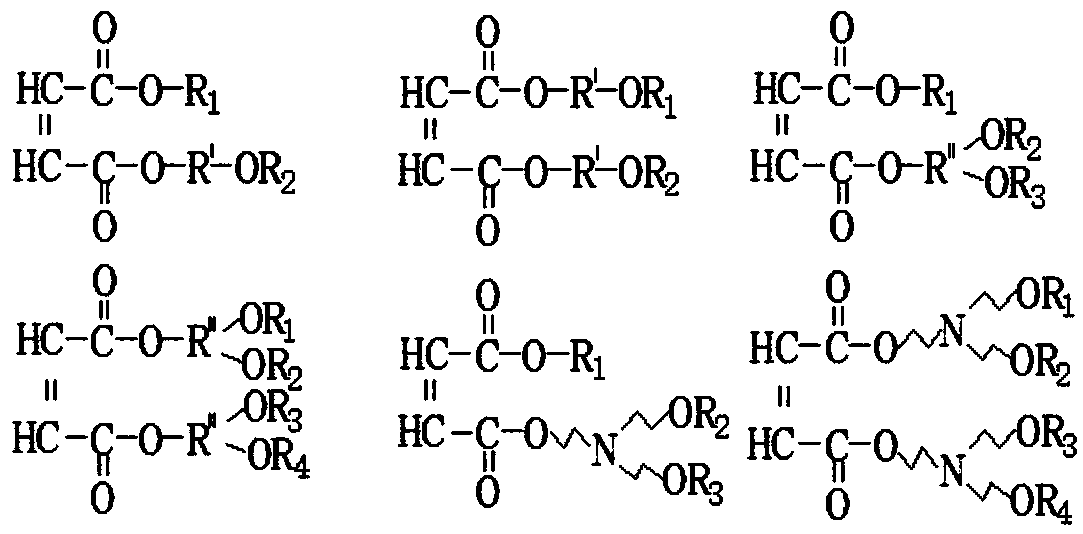

Method used

Image

Examples

Embodiment 1

[0045] Add 1 mole (282g) of diglycerol maleate into the autoclave, add 0.125 moles (3g) of catalyst sodium hydride, and heat up to 105°C after nitrogen replacement, gradually feed 50 moles (2200g) of ethylene oxide Addition reaction of alkane, heating up to 150°C, gradually feeding 5 moles (290g) of propylene oxide, after the reaction, then feeding 50 moles (2200g) of ethylene oxide at 120°C for reaction, and then feeding 5 moles (290g) of propylene oxide, then pass into the oxyethane of 50 moles (2200g), treat that reaction finishes, obtain diglycerol maleate polyoxyethylene ether, be cooled to 70 ℃ of discharging, weigh The average molecular weight is 7462.

Embodiment 2

[0047] Add 1 mole of bis-triethanolamine maleate (396g) into the autoclave, add 0.09 mole of catalyst sodium ethylate (6g), replace with nitrogen and heat up to 120°C, gradually feed 45 moles of ethylene oxide (1980g) for addition reaction, heated up to 140°C, then gradually introduced 2 moles (290g) of propylene oxide, after the reaction, added 35 moles of ethylene oxide (1540g), 5 moles of propylene oxide (290g ), then 45 moles (1980g) of ethylene oxide were introduced at 120°C for reaction, after the reaction, the temperature was raised to 150°C, 8 moles of propylene oxide (290g) were added for addition, and then 55 moles of ethylene oxide were passed into Addition reaction of alkanes (2420g) was carried out. After the reaction was completed, bis-triethanolamine maleate polyoxyethylene ether was obtained, and the temperature was lowered to 70°C to discharge the material, with a weight average molecular weight of 9186.

Embodiment 3

[0049] Add 1 mole of monoethylene glycol maleate (160g) into the autoclave, add 0.1 mole of catalyst sodium hydride (2.5g), replace with nitrogen and heat up to 120°C, gradually feed 10 moles of epoxy Ethane (440g) carries out addition reaction, and middle block is passed into the propylene oxide (174g) of 3 moles, finally passes into the oxyethane (1320g) of 30 moles, treats that reaction finishes, obtains maleic acid Monoethylene glycol ester polyoxyethylene ether, cooled to 65°C and discharged, with a weight average molecular weight of 2094.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com