Method for obtaining formamidinium bromide/PMMA composite material through in-situ polymerization cladding and application thereof

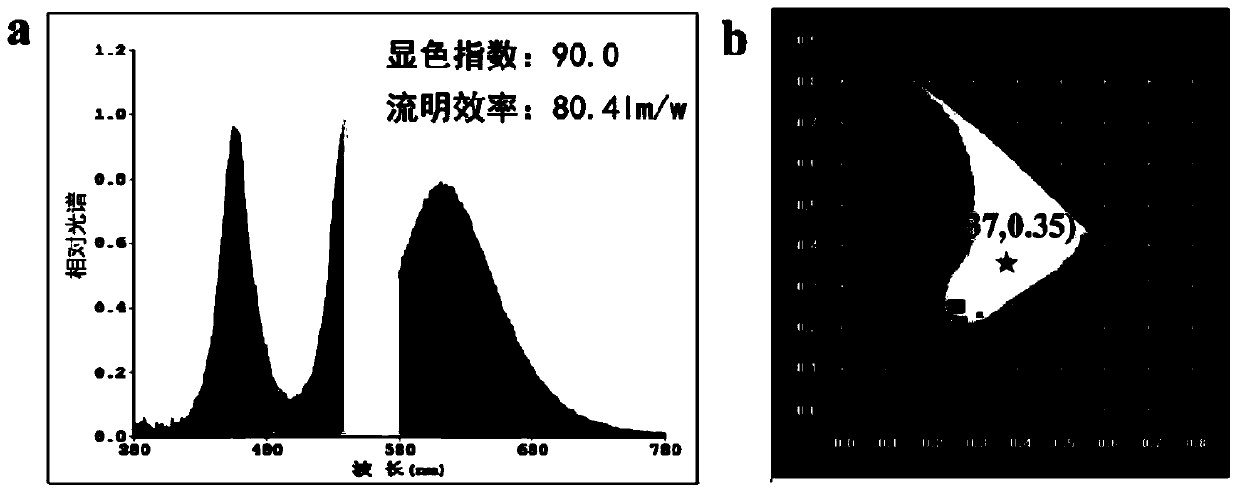

A technology of in situ polymerization, composite materials, applied in nanotechnology, luminescent materials, chemical instruments and methods for materials and surface science, etc., can solve the problem of quantum dot luminous efficiency decline, perovskite quantum dot agglomeration, limited commercial It is suitable for industrialized large-area production, excellent stability, and the removal of LED packaging steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

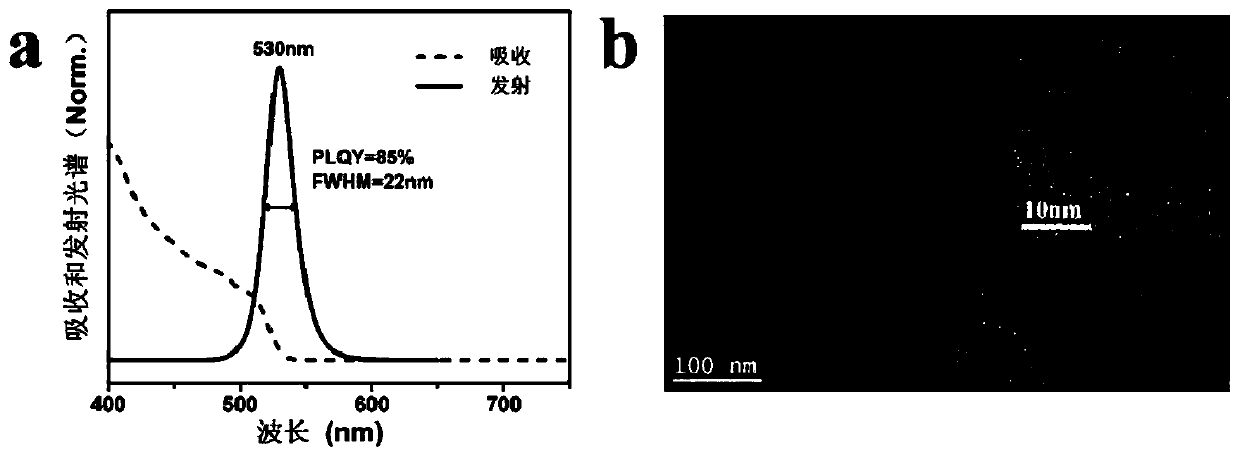

[0037] Example 1: Synthesis and purification of formamidine lead bromine perovskite quantum dots

[0038] 1a. Synthesis of oleylamine bromide precursor

[0039] Use oleylamine and hydrobromic acid as raw materials, absolute ethanol as the reaction solvent, react in an ice bath under the protection of an inert gas for 8-12 hours, vacuum dry, wash with anhydrous ether and filter, vacuum dry, and grind to obtain oleylamine Bromine white powder. The volume ratio of oleylamine, hydrobromic acid and absolute ethanol is 5:4:10-100.

[0040] 1b. Synthesis of formamidine lead bromine quantum dots

[0041] Using oleic acid as a ligand, dissolve formamidine acetate and lead acetate in octadecene, heat the mixed solution to 50-80°C and vacuumize for 30 minutes; add the oleylamine bromide obtained in step 1a to toluene, heat to dissolve, and then Under nitrogen protection at 130°C, the toluene solution of oleylamine bromide was added to the reaction system of 1b. After reacting for 10 s...

Embodiment 2

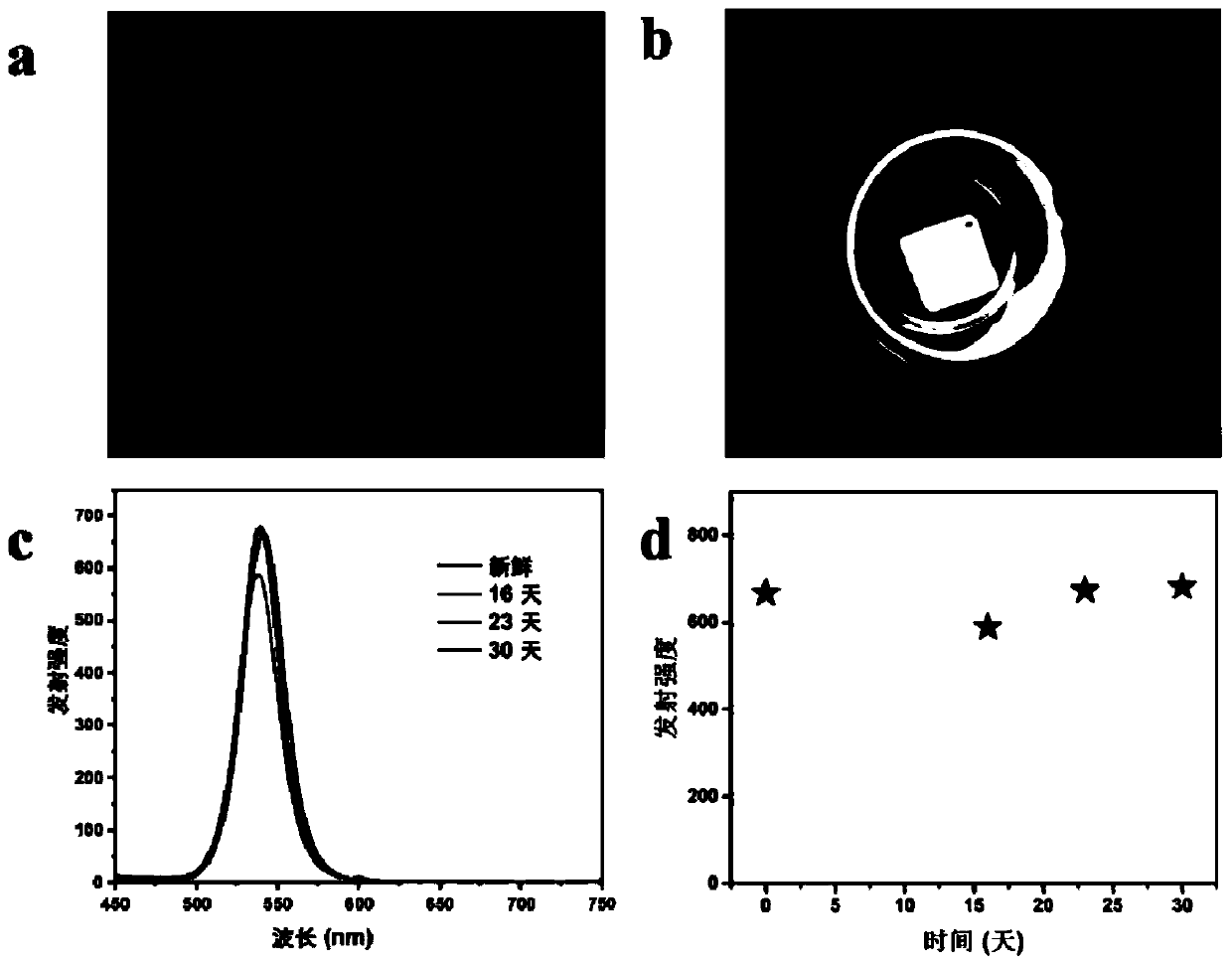

[0045] Embodiment 2: preparation of formamidine lead bromine quantum dots and PMMA composite material

[0046] 2a. Preparation of mixed solution of formamidine lead bromine quantum dots and MMA

[0047] Take 40mg of the quantum dot powder in step 1c, put it into a glass container, add 10mL of MMA solution, make it fully contact and mix evenly through processes such as ultrasound and stirring, and seal it with a parafilm.

[0048] 2b. Illumination polymerization reaction of formamidine lead bromine quantum dots and MMA

[0049] The mixed solution in step 2a is placed under white light for light reaction, stirring continuously during the reaction, and the reaction is completed after 9-12 hours of reaction, and the solution becomes viscous.

Embodiment 3

[0050] Embodiment 3: preparation of formamidine lead bromine quantum dots / PMMA composite film

[0051] Pour the reacted solution in step 2b onto a smooth copper foil (the copper foil is fixed on the glass substrate), and use a spatula to evenly cover the reaction product on the copper foil, while the thickness of the film is controlled to 400um by the spatula. Place the glass substrate uniformly covered with the reaction product on a 60 °C heating plate to remove excess MMA monomer. After 2 minutes, take out the glass substrate, and use a cutting tool to cut out a green quantum dot composite film of an appropriate size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com