Preparation method of easy-to-activate high-carrying-capacity lithium sulfide carbon composite material and application of preparation method

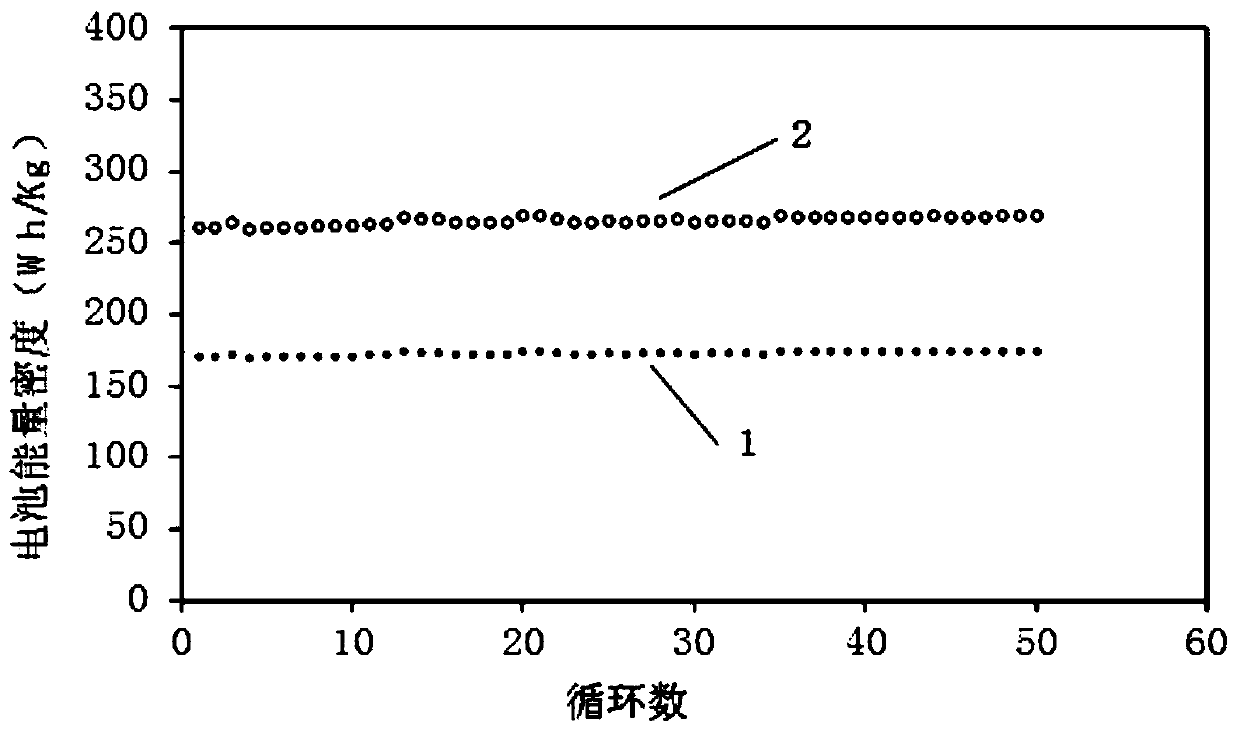

A carbon composite material and lithium sulfide technology, which is applied in lithium batteries, active material electrodes, electrical components, etc., can solve the problems of poor activity of lithium sulfide electrodes and difficult activation of lithium sulfide batteries, so as to improve the safety of preparation and the activation performance , the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment one: preparation of glucose thiourea prepolymer

[0043] Dissolve 3.96 g of glucose monohydrate in 3.96 mL of deionized water, and dissolve 1.52 g of thiourea in 6 mL of deionized water. At this time, the molar ratio of glucose to thiourea is 1:1. The thiourea solution was added to the glucose solution, placed in a water bath at 85° C., and 10 wt % hydrochloric acid was added dropwise and fully stirred to keep the pH value at 1. After reacting for 45 minutes, the viscosity of the liquid increased significantly, and after the color changed to reddish brown, 48 mL of deionized water was added to terminate the polymerization, and cooled to obtain a glucose thiourea prepolymer solution.

Embodiment 2

[0044] Example 2: Preparation of primary carbon-coated lithium sulfate

[0045] Lithium sulfate monohydrate is dissolved in its 4 times of mass ion water, lithium sulfate solution is added to the glucose thiourea prepolymer solution of the gained embodiment one, until half of the glucose amount used for the synthesis of glucose thiourea prepolymer (glucose and The mass ratio of lithium sulfate is 1:0.5), heated in a water bath at 85°C, stirred and reacted for 50 minutes, and then spray-dried.

[0046] The powder obtained by drying was heated from room temperature to 160°C at a rate of 10°C / min under a nitrogen atmosphere, and kept for 2 hours to carry out deep polymerization of glucose thiourea resin. Then the temperature was raised to 500°C at a rate of 10°C / min, and kept for 2 hours for initial carbonization. After cooling, it was taken out to obtain primary carbon-coated lithium sulfate.

Embodiment 3

[0047] Example 3: Preparation of Secondary Coating Lithium Sulfate

[0048] Lithium sulfate monohydrate is dissolved in its 4 times of mass ion water, and lithium sulfate solution is added the glucose thiourea prepolymer solution of embodiment one gain, until the quality of the glucose amount that synthetic glucose thiourea prepolymer uses is identical (glucose and The mass ratio of lithium sulfate is 1:1), heated in a water bath at 85°C, stirred and reacted for 50 minutes, and then spray-dried.

[0049] The powder obtained by drying was heated from room temperature to 160°C at a rate of 10°C / min under a nitrogen atmosphere, and kept for 2 hours to carry out deep polymerization of glucose thiourea resin. Then the temperature was raised to 600°C at a rate of 10°C / min, and the temperature was kept for 2 hours for initial carbonization. After cooling, it was taken out to obtain primary carbon-coated lithium sulfate.

[0050] Ball mill the above materials to a particle size of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com