Polymer single ion conductor and preparation method thereof, composite cathode and solid state lithium battery

A lithium-sulfur battery, composite cathode technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc. It can improve the cycle stability performance, improve the battery coulombic efficiency, and reduce the polarization effect of charge and discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the above-mentioned polymer single ion conductor, comprising the following steps:

[0047] A) dissolving the carboxyl-containing polymer having the structure of formula (I) in deionized water to obtain an aqueous solution of the carboxyl-containing polymer;

[0048] B) adding lithium hydroxide to the aqueous solution of the carboxyl-containing polymer, mixing and stirring, and reacting to obtain a polymer single ion conductor;

[0049] Specifically, the carboxyl-containing polymer having the structure of formula (I) is dissolved in deionized water to obtain an aqueous solution of the carboxyl-containing polymer; the concentration of the carboxyl-containing polymer in the aqueous solution of the carboxyl-containing polymer is 0.01 wt%-50wt%, preferably 0.1wt%-40wt%, more preferably 1wt%-30wt%, even more preferably 5wt%-25wt%.

[0050] Next, lithium hydroxide was added to the aqueous solution of the carboxyl grou...

Embodiment 1

[0087] Polyacrylic acid (M w =4000000) was dissolved in deionized water to prepare a polyacrylic acid solution with a mass fraction of 1%. According to the stoichiometric ratio of carboxyl group: hydroxide group of 1:1, add lithium hydroxide and stir magnetically for one hour to obtain lithium polyacrylate hydrogel, and the lithium polyacrylate powder obtained after evaporating the solvent is a lithium ion single ion conductor .

[0088]

[0089] lithium polyacrylate

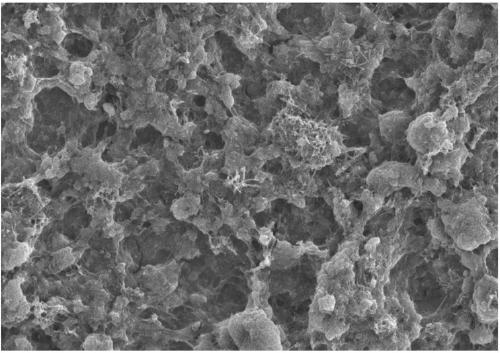

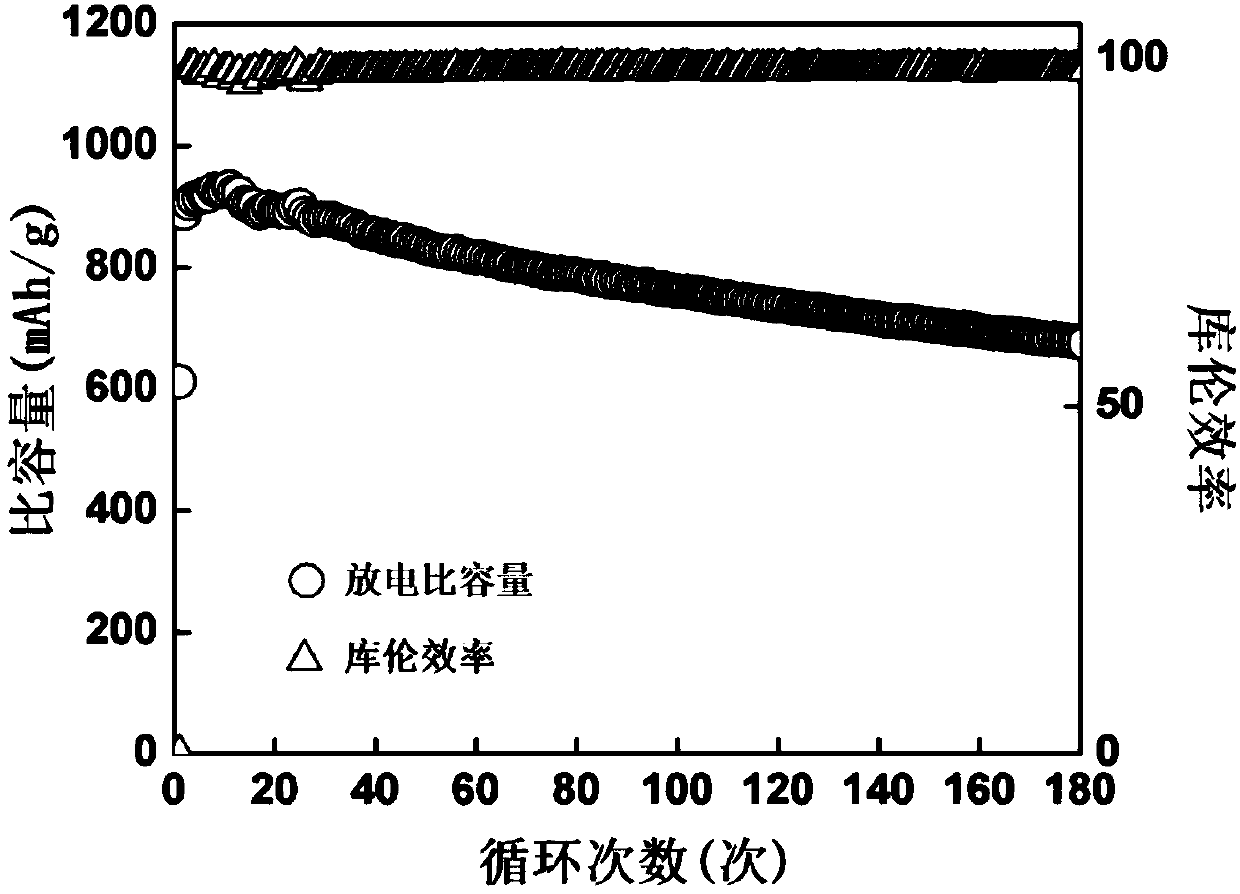

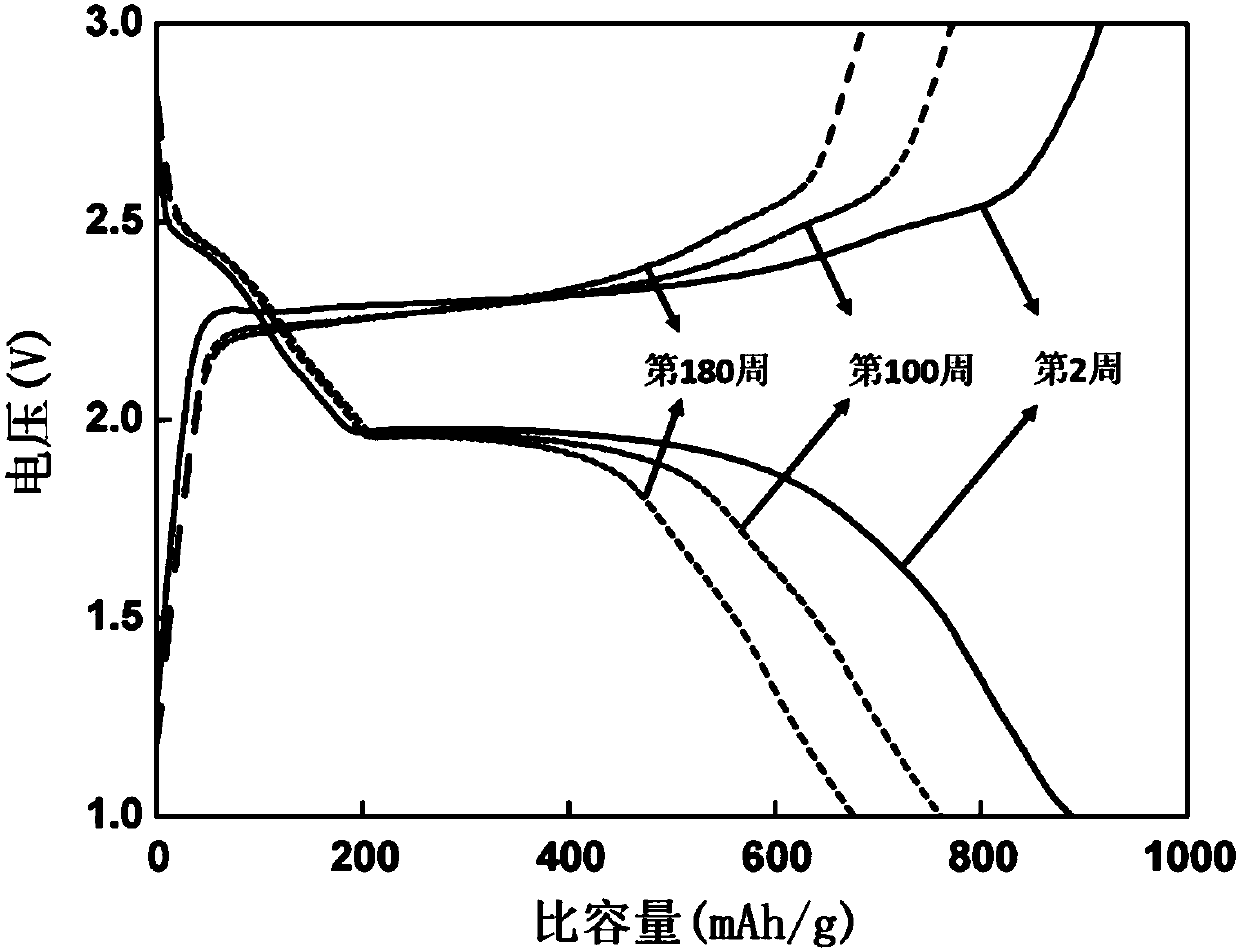

[0090] Take by weighing acetylene black-sulfur composite material (sulfur content=80%wt), VGCF carbon fiber and polyacrylic acid lithium with the mass ratio of 8:1:1, disperse with deionized water, make the slurry solid content be 8%, the slurry The material was ball-milled for 6 hours and evenly coated on aluminum foil, and then vacuum-dried at 60°C for 8 hours to obtain a sulfur cathode. Carry out scanning electron microscope observation to described anode, the result sees figure 1 , figure 1 A scannin...

Embodiment 2

[0093] Polymaleic acid (M w =50000) was dissolved in deionized water to prepare a polymaleic acid solution with a mass fraction of 2%. According to the stoichiometric ratio of carboxyl group: hydroxide group of 1:1, lithium hydroxide was added and magnetically stirred for one hour to obtain polylithium maleate hydrogel.

[0094]

[0095] Lithium polymaleate

[0096] with BF 3 : Li is added to BF at a stoichiometric ratio of 1:1 3 2H 2 O, magnetic stirring evenly. Take by weighing VGCF carbon fiber-sulfur composite material (sulfur content=80%wt) and SuperP with the mass ratio of 17:1, add this hydrogel, make sulfur carbon composite material, the mass ratio of SuperP and polylithium maleate is 17 :1:2, after dispersing with magnetic stirring for 30 minutes, add an appropriate amount of deionized water to make the solid content of the slurry 8%, ball mill the slurry for 8 hours, and evenly coat it on the aluminum foil, and dry it in vacuum at 60°C for 8 Hours later, a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com