Dye-fixing agent used for active dyes, and preparation method thereof

A technology of reactive dyes and color-fixing agents, applied in dyeing, textiles and papermaking, etc., can solve the problems of insufficient supply of raw materials, easy color change, harmful formaldehyde, etc., and achieve good color fastness to soaping, good color fastness Rubbing color fastness, effect of improving color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

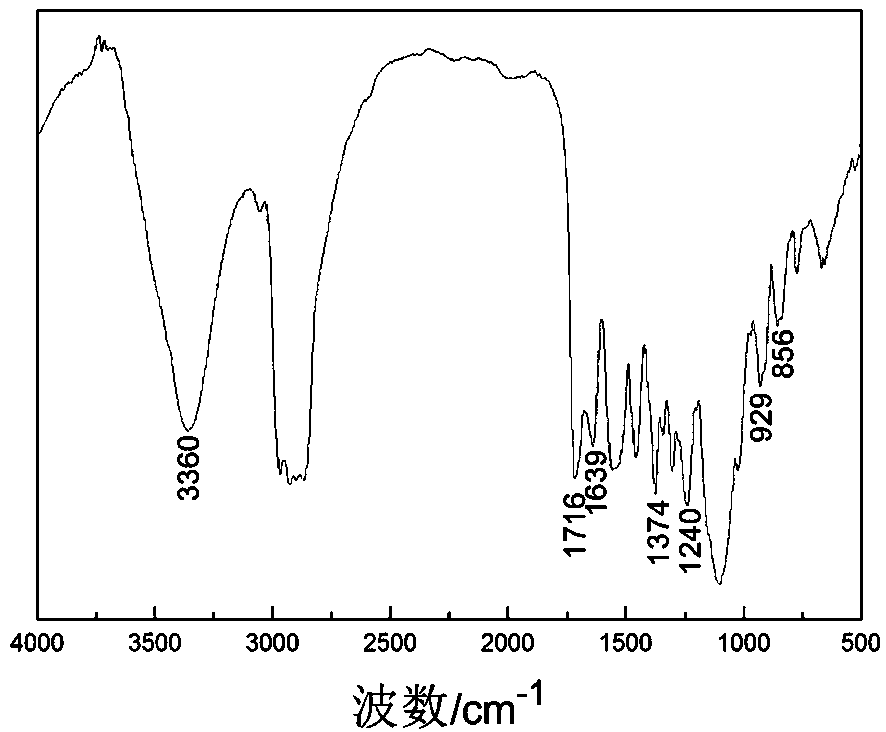

Embodiment 1

[0034] This embodiment provides a method for preparing a color-fixing agent for reactive dyes, and the synthesis reaction scheme is as follows:

[0035]

[0036] Among them, R means ;

[0037]

[0038] Among them, R means ; 1 express ; 2 express , 9≤m≤17;

[0039] " " express , 9≤m≤17;

[0040] DBTDL stands for dibutyltin dilaurate.

[0041] Specific steps are as follows:

[0042] (1) Add 6.1g of monoethanolamine into a reaction vessel equipped with a stirrer, dropping device and condensing reflux device, heat up to 20°C, add 22g of 1,4-butanediol diglycidyl ether dropwise in 0.5h After completion, continue the heat preservation reaction for 1 hour; then heat up to 50°C, add 22g of 1,4-butanediol diglycidyl ether dropwise in 0.5 hours, and continue heat preservation reaction for 3 hours to obtain a chain extender.

[0043] (2) Add 4.9g of isophorone diisocyanate and 6g of polypropylene glycol into a reaction vessel equipped with a stirrer, thermometer ...

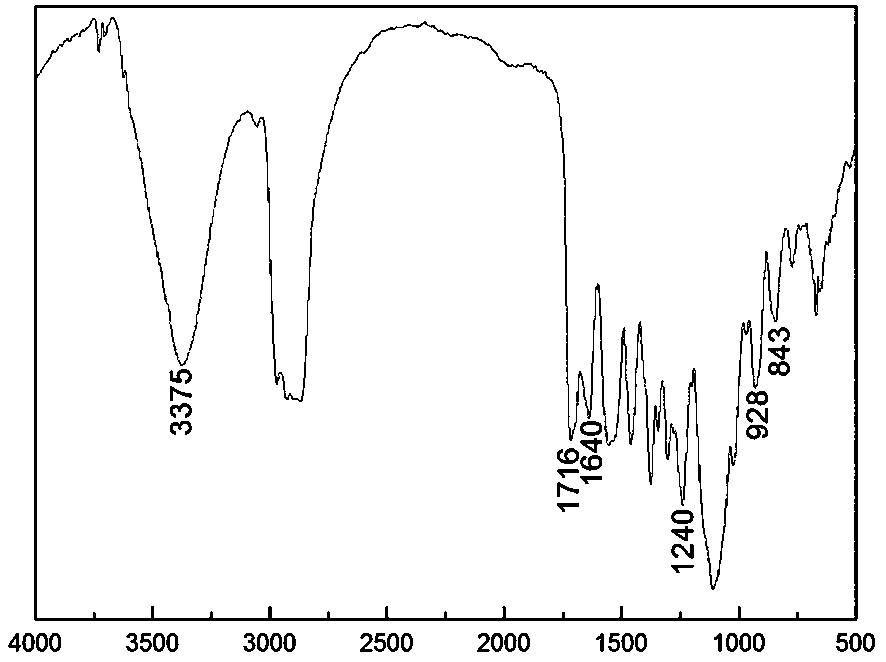

Embodiment 2

[0046](1) Add 6.1g of monoethanolamine into a reaction vessel equipped with a stirrer, dripping device and condensing reflux device, heat up to 25°C, and drop 24.2g of 1,4-butanediol diglycidyl ether in 0.5h After the addition is complete, continue the heat preservation reaction for 1.5 hours; then heat up to 55°C, add 24.2g of 1,4-butanediol diglycidyl ether dropwise in 0.5 hours, and continue the heat preservation reaction for 3.5 hours to obtain a chain extender.

[0047] (2) Add 4.9g of isophorone diisocyanate and 8g of polypropylene glycol into a reaction vessel equipped with a stirrer, thermometer and condensation reflux device, add 5g of acetone as a solvent, 0.01g of dibutyltin dilaurate as a catalyst, and open Condensing device and agitator, after 8 minutes of nitrogen gas, heat up to 75°C, keep warm for 2.5h; add the mixed solution of 1.2g chain extender and 5g acetone obtained in step (1), keep warm for 1.5h; cool down to 45 ℃, add 0.6g methyl ethyl ketoxime and kee...

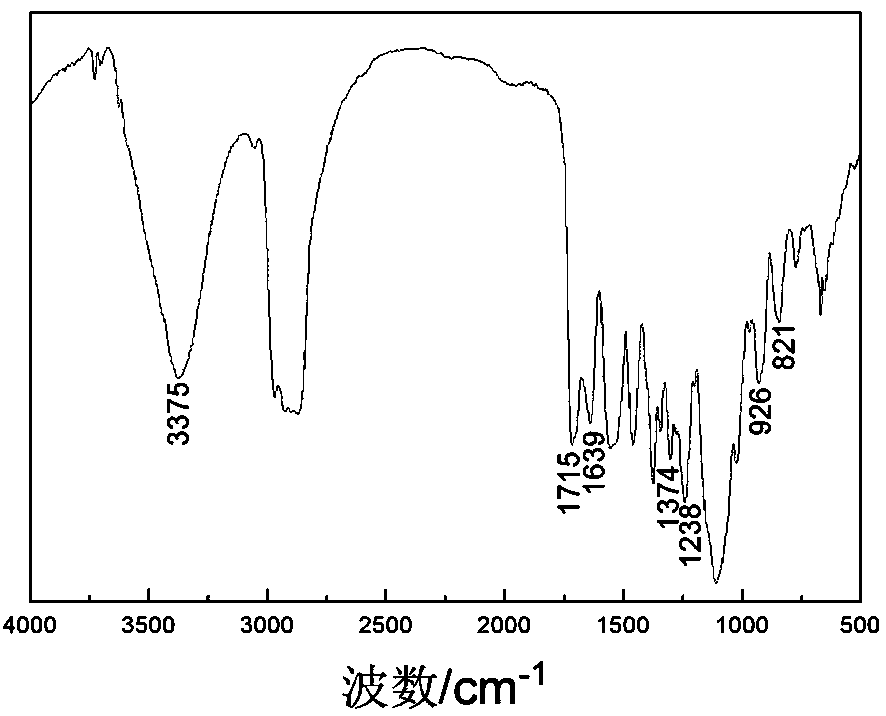

Embodiment 3

[0050] (1) Add 6.1g of monoethanolamine into a reaction vessel equipped with a stirrer, dripping device and condensing reflux device, heat up to 30°C, and drop 26.41,4-butanediol diglycidyl ether in 1 hour. , continue the heat preservation reaction for 2 hours; heat up to 60° C., add 26.4 g of 1,4-butanediol diglycidyl ether dropwise in 1 hour, and continue heat preservation reaction for 4 hours to obtain a chain extender.

[0051] (2) Add 4.9g of isophorone diisocyanate and 10g of polypropylene glycol into a reaction vessel with a stirrer, a thermometer and a condensation reflux device, then add 6g of acetone as a solvent and 0.015g of dibutyltin dilaurate as a catalyst, Turn on the condensing device and the agitator, pass nitrogen gas for 10 minutes, heat up to 80°C, and keep it warm for 3 hours; add the mixed solution of 1.4g chain extender and 6g of acetone obtained in step (1), keep warm for 2h; cool down to 50°C , add 0.73g of methyl ethyl ketone oxime and keep it warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com