A low-cost method for preparing high-performance anisotropic NdFeB magnetic powder using NdFeB oil-based slice sludge

An anisotropic, NdFeB technology, which is applied in the field of reclaiming NdFeB oil-based slicing sludge to prepare recycled magnetic powder, can solve the problems of large amount of reducing agent Ca, reduce recycling costs, increase sludge oxygen content, etc., and achieve environmental friendliness Recycling of resources, realization of recycling of resources, and the effect of reducing the amount of calcium used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

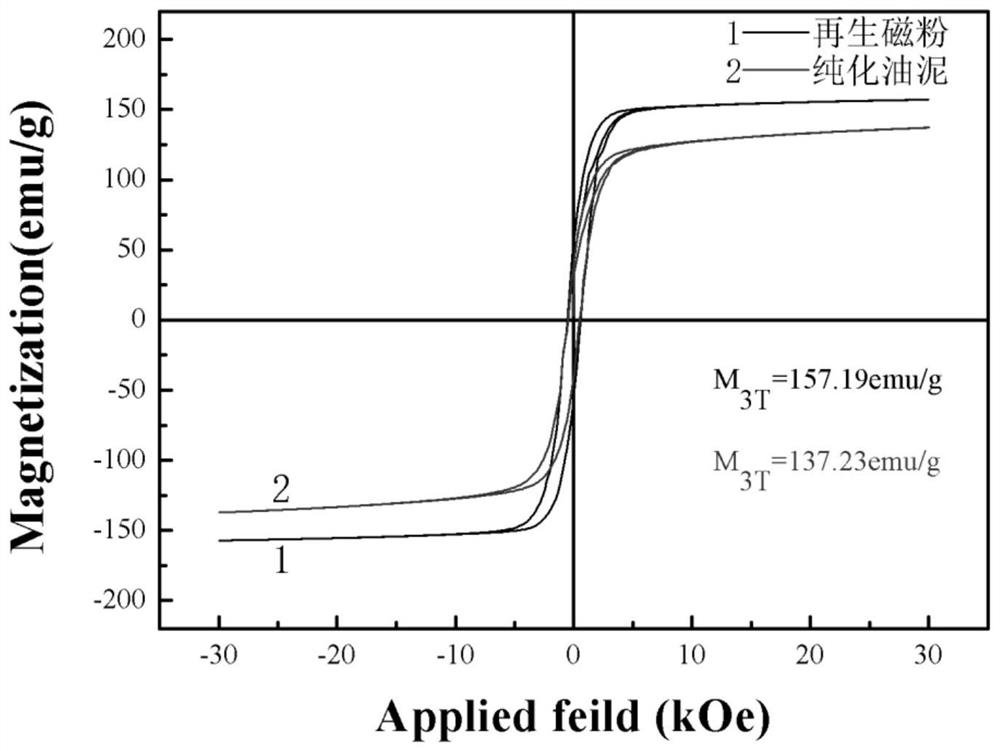

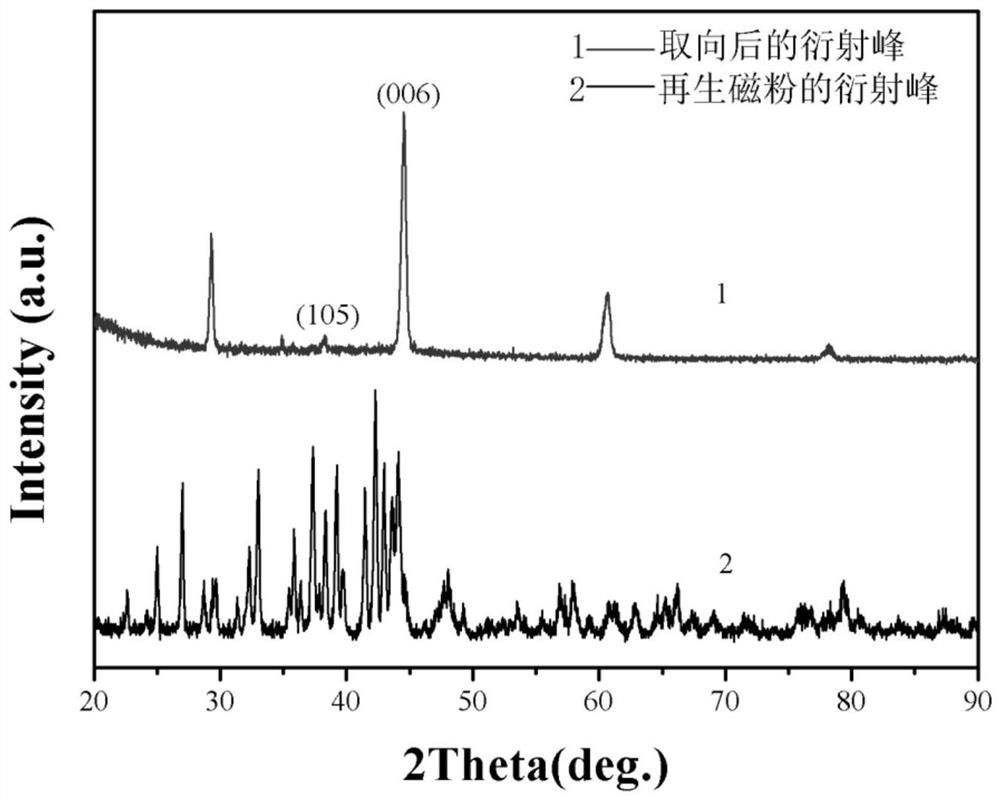

[0021] Take 30g of NdFeB oil-based slice sludge, through sedimentation, centrifugation, and remove cutting fluid, first use OP-NH 4Cl aqueous solution was ultrasonically cleaned twice, distilled water was washed twice, dilute acetic acid solution was used to wash once, distilled water was washed twice, and acetone was finally used to wash once, and dried in a vacuum environment to obtain pretreated sludge. Take 5g of pretreated oil sludge, mix with 0.8g metallic calcium and 2.62g anhydrous calcium chloride, place it in a cemented carbide mold, and press it into a block on a cold press to obtain a reaction block; place the reaction block on a stainless steel Put the crucible in a tube furnace, raise the temperature to 1050°C in an argon atmosphere, and keep it warm for 120 minutes to obtain a reduced block; grind the reduced block into powder, and carry out the process in a container with an external magnet and a mixture of ice and water Remove calcium, soak for 10 minutes, rem...

Embodiment 2

[0023] Take 30g of NdFeB oil-based slice sludge, through sedimentation, centrifugation, and remove cutting fluid, first use OP-NaHCO 3 The aqueous solution is ultrasonically cleaned twice, distilled water is washed twice, then dilute nitric acid solution is used for washing, distilled water is washed twice, and finally acetone is used for washing once, and the pretreated sludge is obtained by drying in a vacuum environment. Take 5g of pretreated oil sludge, mix with 1g of calcium metal, and 2.62g of anhydrous calcium chloride, place it in a cemented carbide mold, and press it into a block on a cold press to obtain a reaction block; put the reaction block in a stainless steel crucible In the process, put the crucible in a tube furnace, raise the temperature to 1050°C in an argon atmosphere, and keep it warm for 120 minutes to obtain a reduced block; grind the reduced block into powder, and remove it in a container with an external magnet and equipped with an ice-water mixture. ...

Embodiment 3

[0025] Take 30g of NdFeB oil-based slice sludge, through sedimentation, centrifugation, and remove cutting fluid, first use OP-Na 2 CO 3 The aqueous solution is ultrasonically cleaned twice, distilled water is washed twice, then dilute sulfuric acid solution is used for washing, distilled water is washed twice, and finally acetone is used for washing once, and the pretreated oil sludge is obtained by drying in a vacuum environment. Take 5g of pretreated oil sludge, mix with 1.1g metallic calcium and 2.62g anhydrous calcium chloride, place it in a cemented carbide mold, and press it into a block on a cold press to obtain a reaction block; place the reaction block on a stainless steel Put the crucible in a tube furnace, raise the temperature to 1050°C in an argon atmosphere, and keep it warm for 120 minutes to obtain a reduced block; grind the reduced block into powder, and carry out the process in a container with an external magnet and a mixture of ice and water Remove calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com