A kind of nano cerium oxide and preparation method thereof

A technology of nano-cerium oxide and cerium salt, which is applied in the direction of cerium oxide/cerium hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of solid-phase method mixing impurities, complicated preparation process, and insufficient product purity, and achieve continuous operation procedures Adjustable, easy to industrialized production, easy to test the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

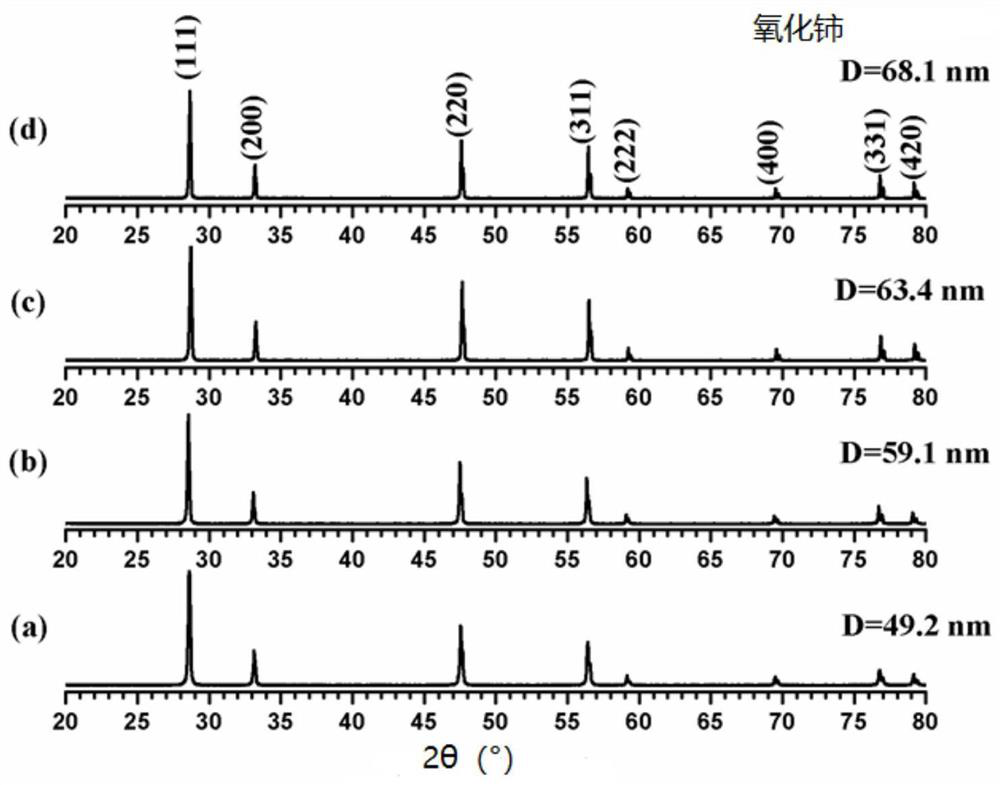

[0030] (1) The effects of different calcination temperatures on the particle size, crystal type and particle morphology of cerium oxide were studied. Specifically as follows:

[0031] Prepare cerium oxide powder, the specific preparation method comprises the following steps:

[0032] S1. Weigh 8.6844g cerous nitrate hexahydrate (0.02mol) and 3.1800g sodium carbonate (0.03mol) in a ceramic mortar with a diameter of 160mm to obtain a solid mixture;

[0033] S2, directly grind the solid mixture by hand for 60 minutes, try to rotate in the same direction (clockwise or counterclockwise) when grinding;

[0034] S3. After the reaction is over, transfer the mixture in the ceramic mortar to a 250mL centrifuge bottle, add 100mL to 150mL of deionized water, stir the suspension with a glass rod for 3min to 5min, then centrifuge the suspension, filter, and continue Add deionized water, repeat the steps of washing and centrifugation 3 times, to remove unreacted complete reactant (cerous n...

Embodiment 2

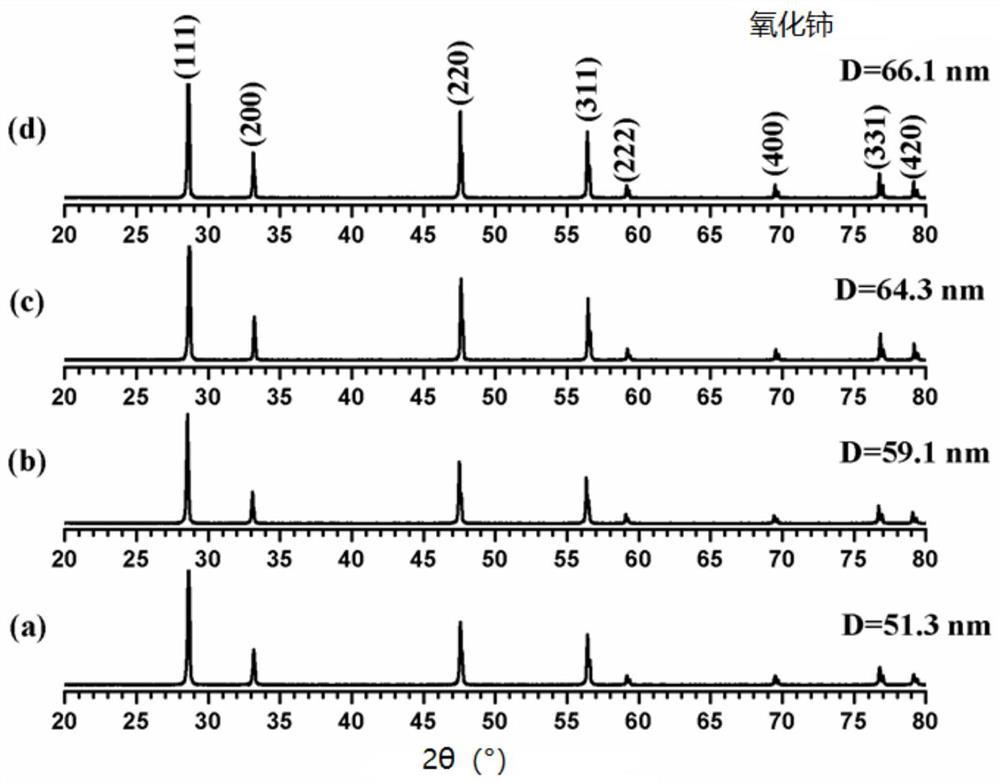

[0043]A preparation method of nano cerium oxide, comprising the following steps:

[0044] S1. Weigh 8.6844g cerous nitrate hexahydrate (0.02mol) and 3.1800g sodium carbonate (0.03mol) in a ceramic mortar with a diameter of 160mm to obtain a solid mixture;

[0045] S2. Add 20mL of alcohol dispersant to the solid mixture, then directly grind the solid mixture by hand for 60 minutes, and try to rotate in the same direction (clockwise or counterclockwise) when grinding;

[0046] S3. After the reaction is over, transfer the mixture in the ceramic mortar to a 250mL centrifuge bottle, add 100mL to 150mL of deionized water, stir the suspension with a glass rod for 3min to 5min, then centrifuge the suspension, filter, and continue Add deionized water, repeat the steps of washing and centrifugation 3 times to remove unreacted reactants (cerium nitrate hexahydrate and sodium carbonate) and sodium nitrate; Drying at low temperature for 0.5-2 hours to obtain the precursor;

[0047] S4. T...

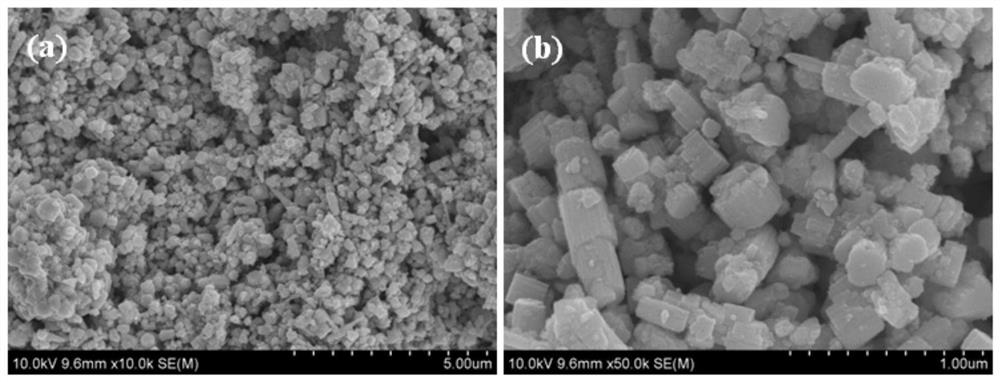

Embodiment 3

[0056] S1. Take by weighing 4.9294g cerium chloride (0.02mol) and 4.1463g potassium carbonate (0.03mol) in a ceramic mortar with a diameter of 160mm to obtain a solid mixture;

[0057] S2. Add 20 mL of glycerol to the solid mixture, then directly grind the solid mixture by hand for 60 minutes, and try to rotate in the same direction (clockwise or counterclockwise) when grinding;

[0058] S3. After the reaction is over, transfer the mixture in the ceramic mortar to a 250mL centrifuge bottle, add 150mL of deionized water, stir the suspension with a glass rod for 3min-5min, then centrifuge the suspension, filter, and continue to add deionized water. Ionized water, repeat the steps of washing and centrifugation 3 times to remove unreacted reactants (cerium chloride and potassium carbonate) and potassium chloride; then dry the solid after centrifugation at a temperature of 60-80°C for 0.5 ~2h, get the precursor;

[0059] S4. The precursor is calcined in a muffle furnace at a calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com