Preparation method of protonated carbon nitride-beta-SiC composite material

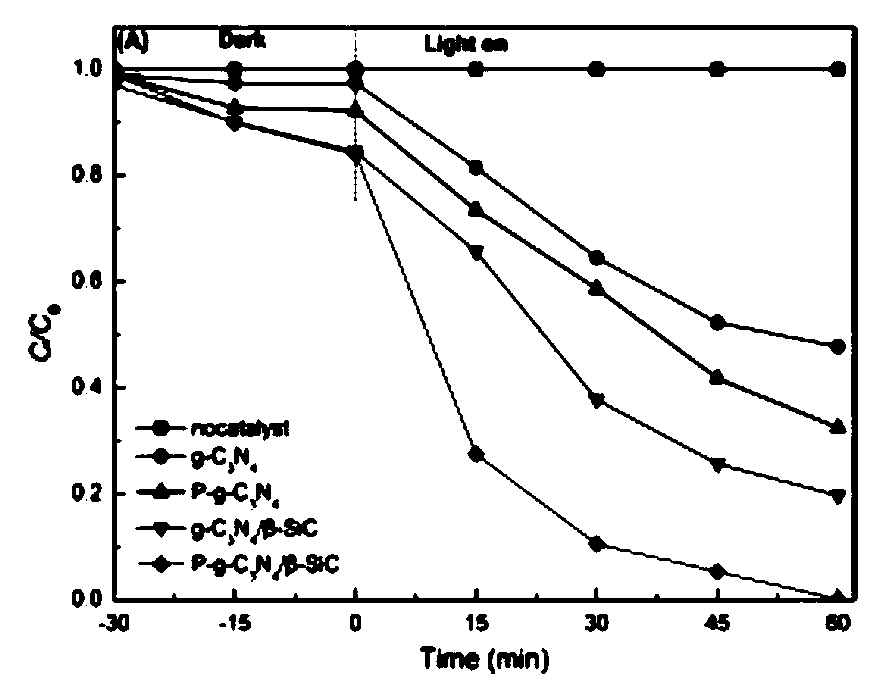

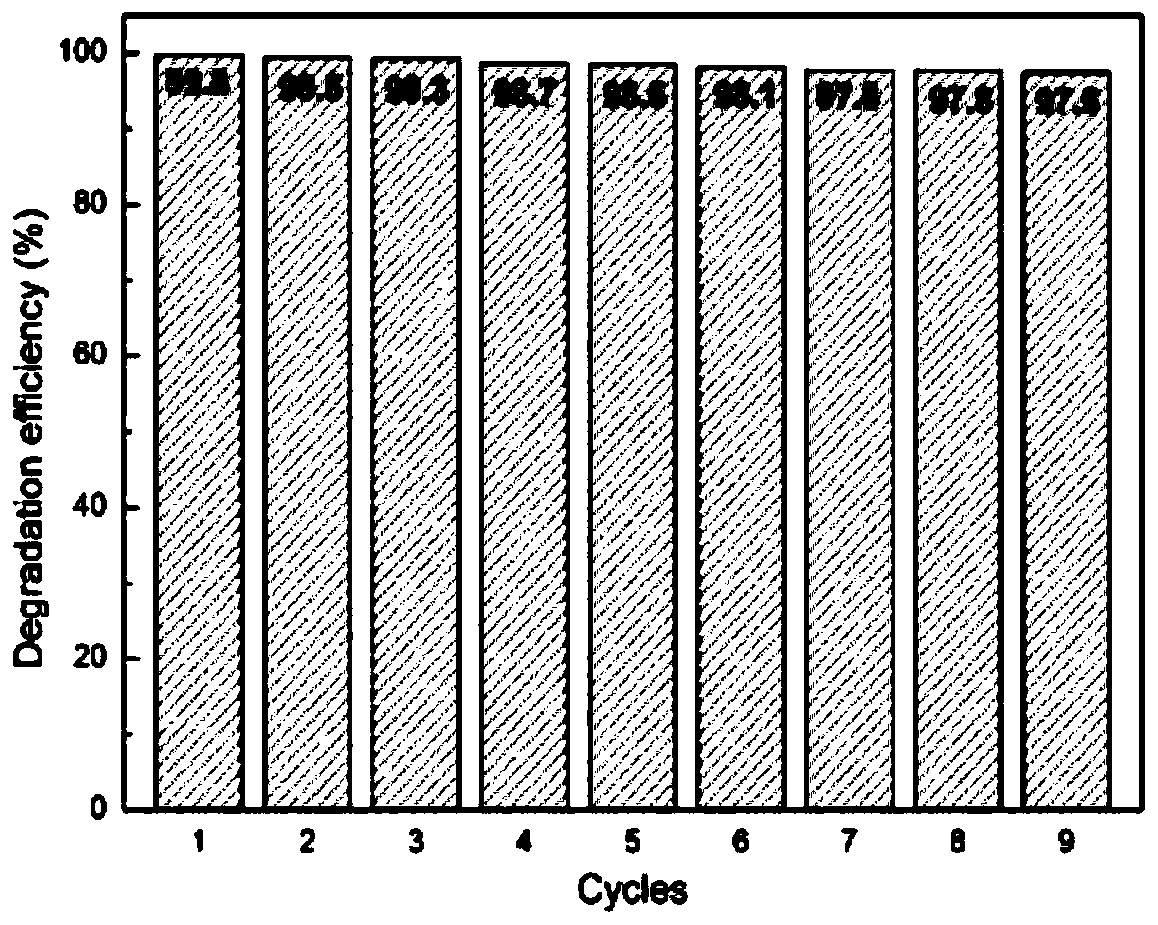

A technology of carbon nitride and composite materials, which is applied in chemical instruments and methods, special compound water treatment, physical/chemical process catalysts, etc., and can solve the problem of not effectively developing the photocatalytic performance of pure crystalline phase β-SiC composite materials. , to achieve the effect of promoting migration rate, high catalytic performance, and inhibiting reorganization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of protonated carbon nitride-β-SiC composite material, comprising the following steps:

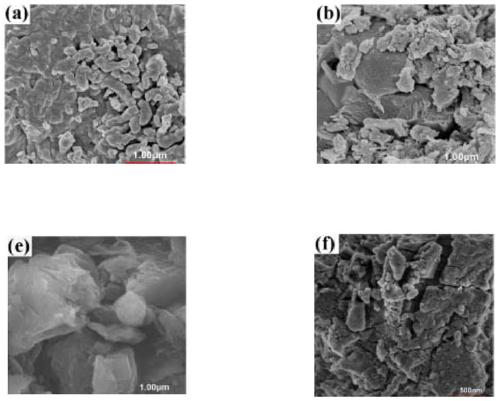

[0028] (1) Preparation of g-C 3 N 4 / β-SiC; put melamine and β-SiC into a flask filled with methanol, stir and mix evenly at room temperature, distill and recover methanol to obtain a powder sample; heat the powder sample to obtain g-C 3 N 4 / β-SiC;

[0029] (2) put g-C 3 N 4 / β-SiC was added to concentrated hydrochloric acid, stirred at room temperature, after the stirring was completed, suction filtered and washed, and dried to obtain protonated carbon nitride-β-SiC.

Embodiment 2

[0031] A preparation method of protonated carbon nitride-β-SiC composite material, comprising the following steps:

[0032] Preparation of β-SiC: Dissolve sodium silicate and ferric nitrate with a molar ratio of 10:1 in a small amount of deionized water, add Taixi coal with an ash content of 0.1%, and the amount of Taixi coal added is the same as the mole of sodium silicate The ratio is 5:1, and the reaction is carried out with stirring at a temperature of 90°C; until the reactant becomes viscous and forms a gel, then dried and pulverized to obtain a silicon carbide precursor; put the silicon carbide precursor into a high-temperature tube In the furnace, under argon atmosphere, the temperature was raised to 1000°C at a rate of 3°C / min, and then raised to 1450°C at a rate of 2°C / min, kept for 5 hours, and then cooled to room temperature at a rate of 3°C / min. A crude silicon carbide product was obtained.

[0033] The crude silicon carbide product was roasted in a muffle furnace...

Embodiment 3

[0038] A preparation method of protonated carbon nitride-β-SiC composite material, comprising the following steps:

[0039] Preparation of β-SiC: Dissolve sodium silicate and ferric nitrate with a molar ratio of 10:1 in a small amount of deionized water, add Taixi coal with an ash content of 0.2%, and the amount of Taixi coal added is the same as the mole of sodium silicate The ratio is 5:1, and the reaction is carried out with stirring at a temperature of 90°C; until the reactant becomes viscous and forms a gel, then dried and pulverized to obtain a silicon carbide precursor; put the silicon carbide precursor into a high-temperature tube In the furnace, under argon atmosphere, the temperature was raised to 1000°C at a rate of 3°C / min, and then raised to 1450°C at a rate of 2°C / min, kept for 5 hours, and then cooled to room temperature at a rate of 3°C / min. A crude silicon carbide product was obtained.

[0040] The crude silicon carbide product was roasted in a muffle furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com