Freeze-dried powder having whitening activity and preparation method and application of freeze-dried powder

A freeze-dried powder and active technology, which is applied in the field of freeze-dried powder with whitening activity and its preparation, can solve the problems of increasing stimuli, easy discoloration, irritation, etc., to reduce production costs, shorten freeze-drying time, and eliminate The effect of stimulating the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 experimental group sample

[0043] 1. Preparation of whitening lyophilized powder

[0044] The formula of each component of the whitening freeze-dried powder is shown in Table 1. Weigh deionized water, tranexamic acid, nicotinamide, mannitol, and ascorbyl glucoside according to the weight ratio. Bottles are filled, and then placed in a vacuum dryer. The vacuum freeze-drying parameters are as follows: first place at -45°C, pre-freeze for 2h; gradient temperature method for one drying, -20°C, 3h; -5°C, 5h; then Carry out secondary drying, quickly raise the temperature to 30°C for 3h, then quickly enter the ultimate vacuum state, and keep at 30°C for 4h.

[0045] Table 1. Formula table of whitening freeze-dried powder

[0046]

[0047] 2. Preparation of whitening freeze-dried powder vehicle

[0048] The formula of the whitening freeze-dried powder solvent is shown in Table 2. After the solvent is prepared, it will be filled in 2.5 mL a...

Embodiment 2

[0052] The preparation of embodiment 2 control group sample

[0053] 1. Preparation of Whitening Essence

[0054] The whitening essence formula is shown in Table 3. According to the increasing dosage of tranexamic acid, niacinamide, and ascorbyl glucoside, three gradient samples were made, and deionized water, glycerin, and sodium hyaluronate were dispersed at 85°C according to the weight ratio. After cooling down to room temperature evenly, add tranexamic acid, nicotinamide, ascorbyl glucoside, propylene glycol, bis(hydroxymethyl)imidazolidinyl urea, and iodopropynyl butyl carbamate and stir to dissolve completely.

[0055] Table 3. Preparation of whitening essence

[0056]

[0057] 2. Preparation of Whitening and Moisturizing Cream

[0058] The formula of whitening and moisturizing cream is shown in Table 4. According to the increase of the dosage of tranexamic acid, niacinamide, and ascorbyl glucoside, three gradient samples were made, and deionized water, glycerin, hy...

Embodiment 3

[0062] The stability test comparison of embodiment 3 experimental group and control group

[0063] 1. The results of formula screening and evaluation of the experimental group are shown in Table 5. Selecting a suitable filler ratio makes the preparation easy to freeze-dry and maintain a good appearance and mechanical strength.

[0064] Table 5. Formula screening table of experimental group

[0065]

[0066] It can be seen from Table 5 that formula 4 has the best molding effect and the best mechanical strength after selecting the ratio of formula 4 based on various technical indicators. Therefore, formula 4 was selected as the experimental group of whitening freeze-dried powder.

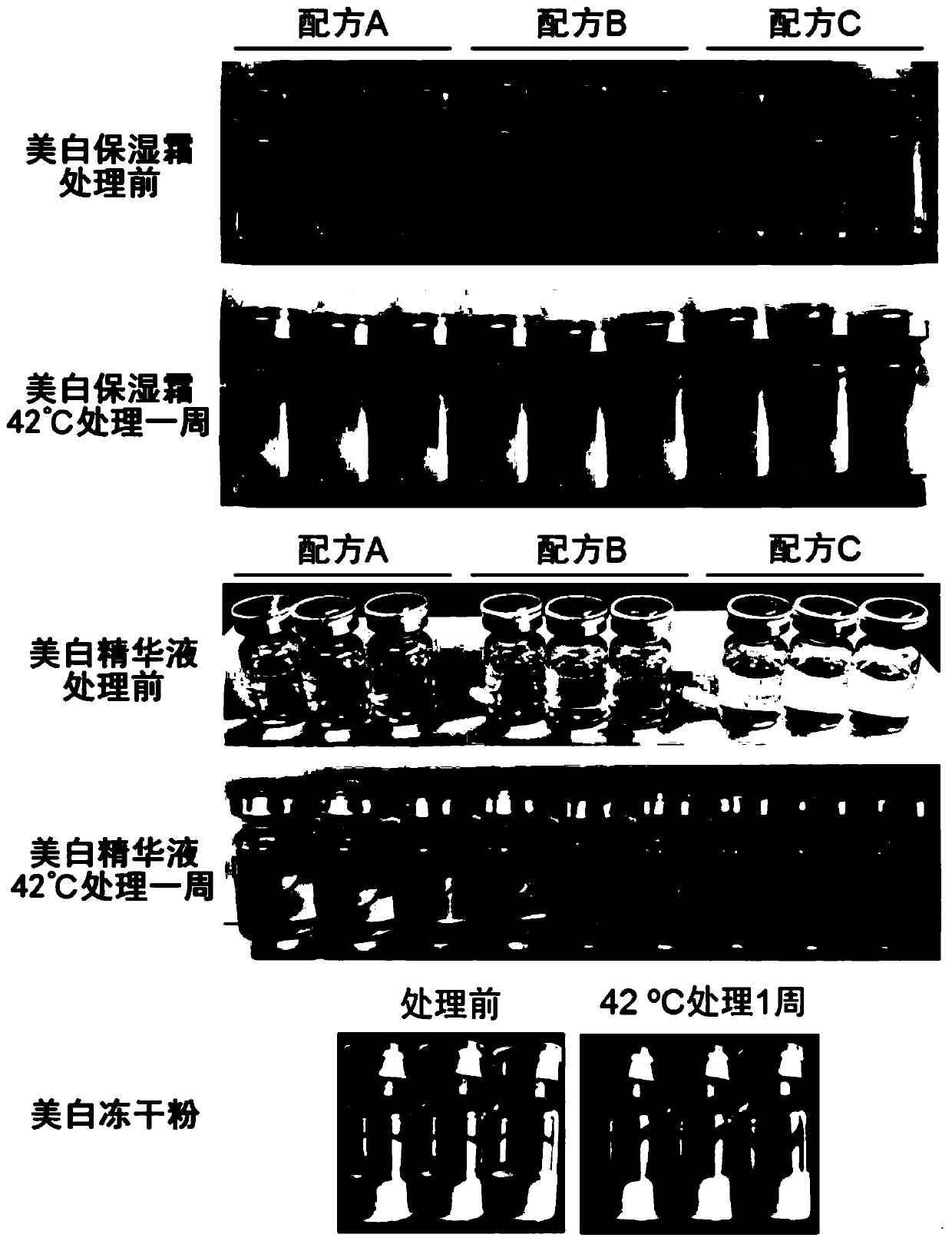

[0067] 2. Stability test comparison such as Table 6 and figure 1 . The ratio of the active whitening ingredients in formula A of the whitening essence and moisturizing cream of the control group was designed according to the ratio of the active whitening ingredients acting on the test body after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com