Environment-friendly mild preparation method of hydrophobic lipophilic sponge

A lipophilic and sponge technology, which is applied in the field of environmentally friendly and mild preparation of hydrophobic and lipophilic sponges, can solve the problems of difficult industrial production, limited practical application, strong corrosiveness and high toxicity, etc., and achieves the effects of mild conditions, outstanding elasticity and efficient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of HDTMS-rGO@MF sponge

[0042] 1) Preparation of graphene oxide

[0043] Prepared according to a modified Hummers method. The preparation of specific graphene oxide is divided into three stages, namely ice bath stage, medium temperature stage and high temperature stage.

[0044]Ice-bath stage: first mix 2g of graphite powder and 1g of sodium nitrate in a 1L glass flask in an ice-water bath at around 0°C, then carefully add 50mL of concentrated sulfuric acid (98wt%), and then slowly magnetically stir the mixture to prevent the mixture from It splashed onto the glass wall and formed a uniform black-gray dispersion after stirring for 10 minutes. Then add 7 g of KnMO in batches 4 , The speed of adding potassium permanganate should be controlled to prevent the temperature of the mixed solution from exceeding 20°C. After the addition, continue to stir for half an hour, and finally form a dark green mixed solution.

[0045] Medium temperature stage: ...

Embodiment 2

[0052] Embodiment 2 prepares the condition optimization of superhydrophobic sponge

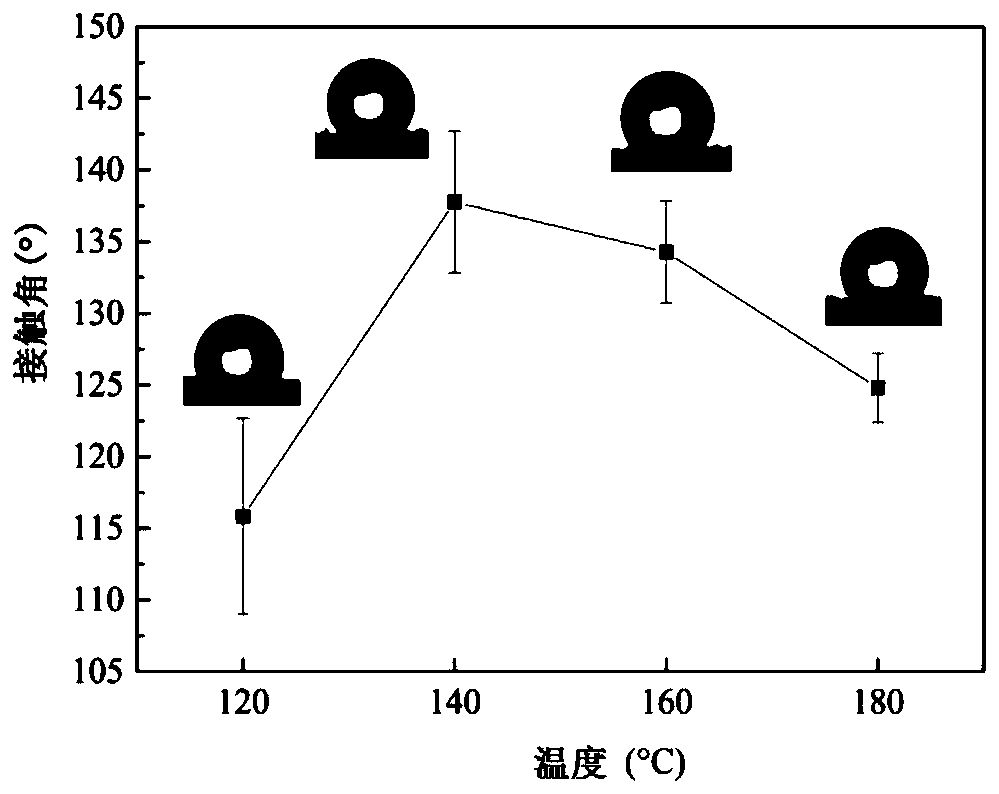

[0053] GO@MF impregnated in HDTMS / ethanol solution was dried under different temperature conditions, such as figure 1 shown. On the one hand, drying promotes the volatilization of the organic solvent ethanol; on the other hand, the temperature affects the reduction degree of GO. At a lower temperature of 120 °C, the GO coated on the MF sponge still retains a large amount of brown color, indicating that most of the GO has not been reduced. As the temperature increases, the color of GO on the MF surface fades rapidly to black, which is a direct evidence of the reduction of GO. At 140 °C, the water repellency angle of the modified MF sponge reaches the maximum. Continue to increase the temperature, but will reduce the contact angle of MF. It may be related to the fact that the reduced GO tends to be denser, the wrinkled surface becomes flatter, and the roughness of the MF sponge is reduced. ...

Embodiment 3

[0057] Example 3 Characterization of HDTMS-rGO@MF sponge

[0058] The surface morphology of the original MF and the modified HDTMS-rGO@MF was observed with a Quanta 400FEG thermal field emission scanning electron microscope produced by FEI, USA. Before testing, the dried samples were sprayed with gold on the surface of the samples by ion sputtering.

[0059] The morphology characteristics of blank MF and HDTMS-rGO@MF were observed by SEM. Such as Figure 5 As shown in (a), the blank MF displays a 3D interconnected porous structure with pore sizes ranging from tens to hundreds of micrometers, and the rich pore structure is important for the internal transport and circulation of substances. A clean and smooth skeleton of blank MF can be found in Figure 5 observed in (b) and 5(c). However, after coating with graphene oxide solution and HDTMS modification, as Figure 5 In (d), the topography of the interior and exterior of the sponge shows wrapped rGO flakes and disordered s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com