Preparation method of spandex with durable resistance to aging

An aging-resistant and high-performance technology, used in climate sustainability, sustainable manufacturing/processing, textile/flexible product manufacturing, etc., can solve the problems of reducing molecular weight, reducing elongation, limiting the wide application of spandex, and achieving The effect of changing and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of spandex with durable anti-aging performance and its preparation method described in the present invention, its preparation steps are as follows:

[0035] 1.) Preparation of prepolymer solution: Add solvent, polyether diol and hydroxyl-terminated polyolefin in sequence in the prepolymerization tank, then add mixed diisocyanate according to the molar ratio of NCO to OH of 1.50 to 2.00, and the prepolymerization reaction temperature The temperature is controlled at 40-50°C, the reaction time is 60-90 minutes, and the reaction is carried out in a nitrogen atmosphere to obtain the prepolymer stock solution;

[0036] 2.) Transfer the obtained prepolymer stock solution to the chain extension tank, add solvent to the prepolymerization tank, fully stir and dissolve, and transfer it to the chain extension tank to form a prepolymer solution;

[0037] 3.) Then, when the temperature of the prepolymer solution is lowered to 6-12°C, the amine solution is slowly added to carr...

Embodiment 1

[0051] Add 8kgDMAc and 10kgPTMG (molecular weight: 2000) into the prepolymerization tank, stir and mix evenly, when the temperature reaches about 25°C, add 2.0kgMDI, raise the temperature to 45°C, and the reaction time is 60min to obtain the prepolymerization product.

[0052] Transfer the pre-polymerization product to the chain extension tank, add 8kg DMAc to the pre-polymerization tank, add cleaning solvent, transfer to the chain extension tank, cool to 10°C, and start slowly dropwise adding the mixed extension product containing ethylenediamine and diethylamine. chain amine solution for chain extension and diethylamine for chain capping. After the reaction is completed, anti-yellowing additives, anti-ultraviolet absorbers, antioxidants, lubricants, matting agents and other additives are added, and the viscosity reaches 7000 poises to obtain a spinning polyurethaneurea solution with a final solid content of 35%. The spinning dope adopts dry spinning technology, oiled, and mo...

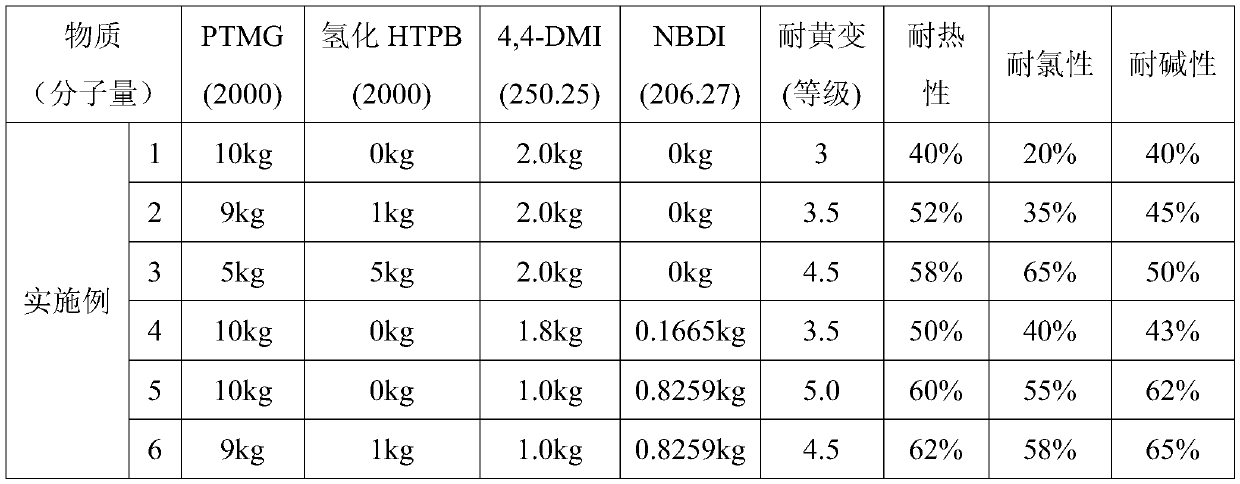

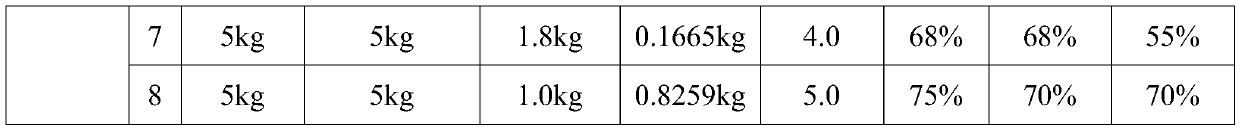

Embodiment 2~8

[0053] Embodiments 2 to 8 are shown in the figure below:

[0054]

[0055]

[0056] Supplementary note:

[0057] The level of yellowing resistance refers to: the sample will be yellowed after being irradiated by ultraviolet lamp for a certain period of time at a certain temperature. The color change of the sample before and after ultraviolet lamp irradiation is detected, and the color difference is calculated.

[0058] High temperature resistance performance refers to: the sample is at a certain temperature, after the silk is shaped at high temperature, it is dyed by a high-temperature dyeing machine, and the change in tensile strength before and after the silk is tested.

[0059] Chlorine resistance refers to: put the sample into a certain concentration of sodium hypochlorite solution, after a certain period of time, after taking it out, detect the change of the tensile strength before and after the wire.

[0060] Alkali resistance performance refers to: put the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com