A kind of sns@nsc core-double shell cubic structure composite material and its preparation method and application

A technology of composite materials and cubes, applied in structural parts, electrical components, battery electrodes, etc., can solve problems that need further improvement and unsolved volume expansion of battery electrodes, and achieve strong surface capacitance dynamics and improve electrochemical performance. Performance, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

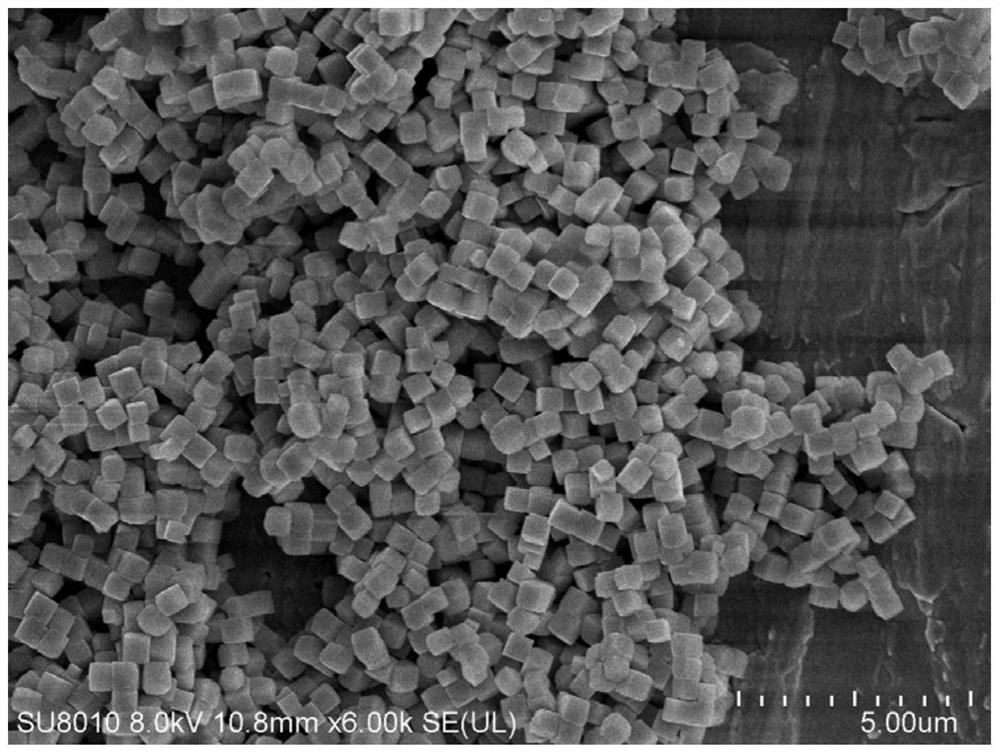

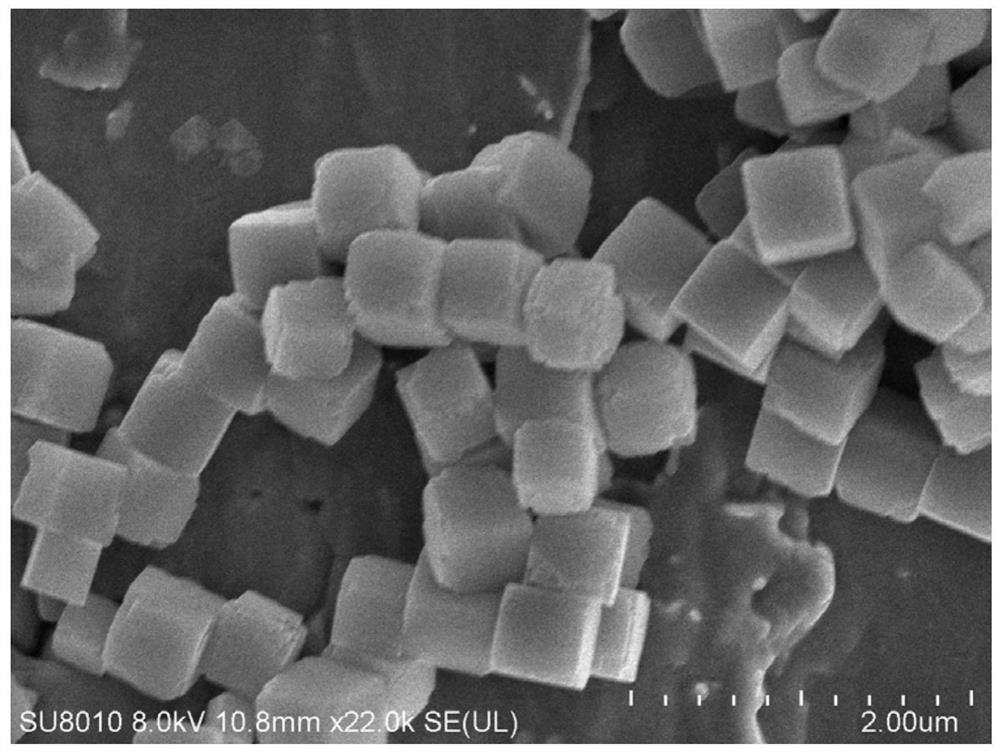

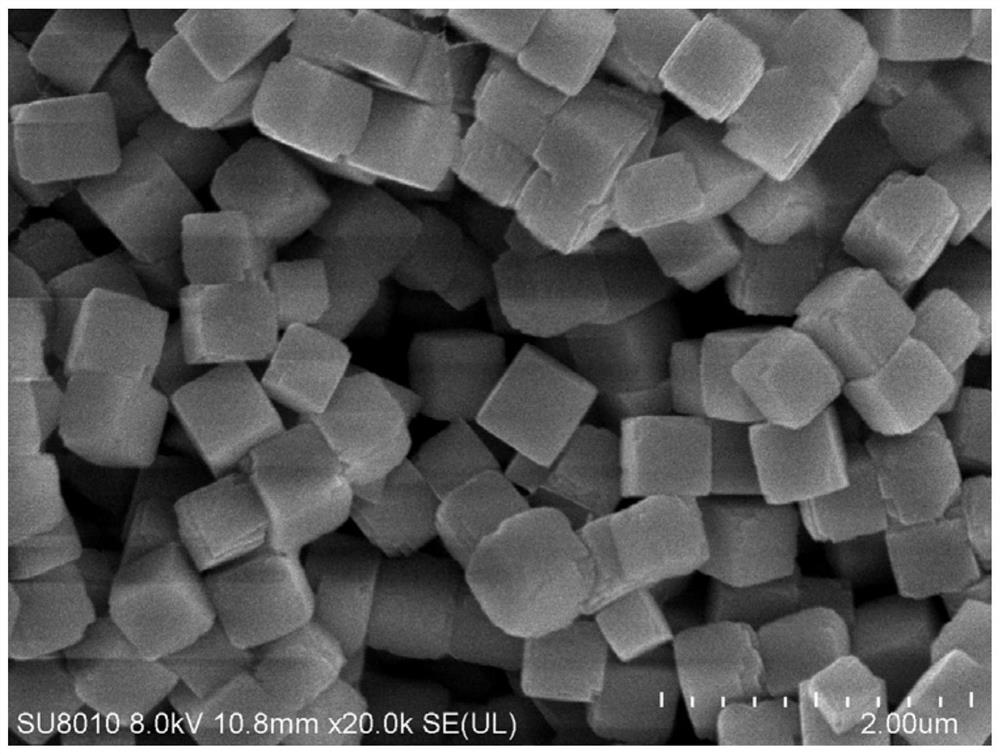

[0042] A SnS@NSC core-double-shell cubic structure composite material, the specific preparation process is as follows:

[0043] S1. Dissolve 50mL of 0.4M SnCl 4 ·5H 2 O solution with 100mL containing 0.2M sodium citrate solution and 100mL 0.1M ZnCl 2 The mixture of the solution was mixed and stirred, and 500 mL of 0.3M NaOH solution was added to the above solution under continuous stirring; after that, it was washed, dried and filtered to obtain a solid cubic precipitate of ZHS.

[0044] S2. Disperse 0.8 g of ZHS cubes in 400 mL of buffer solution and sonicate for 10 minutes; subsequently, add 0.2 g of dopamine and stir at room temperature to form a thin PDA coating; finally, wash, filter and dry to obtain ZHS@PDA black powder.

[0045] S3. Put ZHS@PDA black powder and excess thiourea powder together in a tube furnace, heat to 250°C in a hydrogen atmosphere and keep it warm for 1 hour; after cooling to room temperature, SnS 2 / ZnS@PDA nanocube.

[0046]S4. Selective etchi...

Embodiment 2

[0049] A SnS@NSC core-double-shell cubic structure composite material, the specific preparation process is as follows:

[0050] S1. Dissolve 100mL of 0.2M SnCl 4 ·5H 2 O solution with 100mL containing 0.4M sodium citrate solution and 100mL 0.2M ZnCl 2 The mixture of the solution was mixed and stirred, and 800 mL of 0.2M NaOH solution was added to the above solution under continuous stirring; after that, it was washed, dried and filtered to obtain a solid cubic precipitate of ZHS.

[0051] S2. Disperse 1 g of ZHS cubes in 400 mL of buffer solution and sonicate for 10 minutes. Subsequently, 0.3 g of dopamine was added and stirred at room temperature to form a thin PDA coating; finally, washed, filtered and dried to obtain ZHS@PDA black powder.

[0052] S3. Put ZHS@PDA black powder and excess thiourea powder together in a tube furnace, heat to 250°C in a hydrogen atmosphere and keep it warm for 1 hour; after cooling to room temperature, SnS 2 / ZnS@PDA nanocube.

[0053] S4. ...

Embodiment 3

[0056] A SnS@NSC core-double-shell cubic structure composite material, the specific preparation process is as follows:

[0057] S1. 250mL of 0.2M SnCl 4 ·5H 2 O solution with 250mL containing 0.1M sodium citrate solution and 250mL 0.2M ZnCl 2 The mixture of the solution was mixed and stirred, and 400 mL of 0.3M NaOH solution was added to the above solution under continuous stirring; after that, it was washed, dried and filtered to obtain a solid cubic precipitate of ZHS.

[0058] S2. Disperse 0.6 g of ZHS cubes in 400 mL of buffer solution and sonicate for 10 minutes. Subsequently, 0.2 g of dopamine was added and stirred at room temperature to form a thin PDA coating; finally, washed, filtered and dried to obtain ZHS@PDA black powder.

[0059] S3. Put ZHS@PDA black powder and excess thiourea powder together in a tube furnace, heat to 250°C in a hydrogen atmosphere and keep it warm for 1 hour; after cooling to room temperature, SnS 2 / ZnS@PDA nanocube.

[0060] S4. Selecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com