Preparation method of flexible conductive polyurethane composite film

A flexible conductive and polyurethane technology, applied in the field of composite materials, can solve problems such as easy agglomeration, small improvement in electrical conductivity, and complicated operation, and achieve the effects of improving interface compatibility, improving mechanical properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a flexible conductive polyurethane composite film, comprising the following steps:

[0036] (1) Solvent preparation: mix toluene, N,N-dimethylformamide and dioxane with a mass fraction ratio of 5%:90%:5%, and mix them into a ternary mixed solvent after mechanical stirring ;

[0037] (2) Preparation of casting solution: the polyester polyurethane prepolymer and unmodified carbon nanotubes placed in the ternary mixed solvent prepared in step (1) with a mass fraction ratio of 90%: 10%, wherein poly The mass fraction ratio of the ether type polyurethane prepolymer and the unmodified carbon nanotube mixture to the ternary mixed solvent is 30%:70%, and after mechanical stirring at a speed of 1000r / min for 1.5h at 25°C, vacuum defoaming, Prepared into polyurethane casting solution;

[0038] (3) Coagulation bath preparation: at room temperature, the mass fraction ratio is 90%: 10% deionized water and 1-propanol are mixed, after ...

Embodiment 2~7

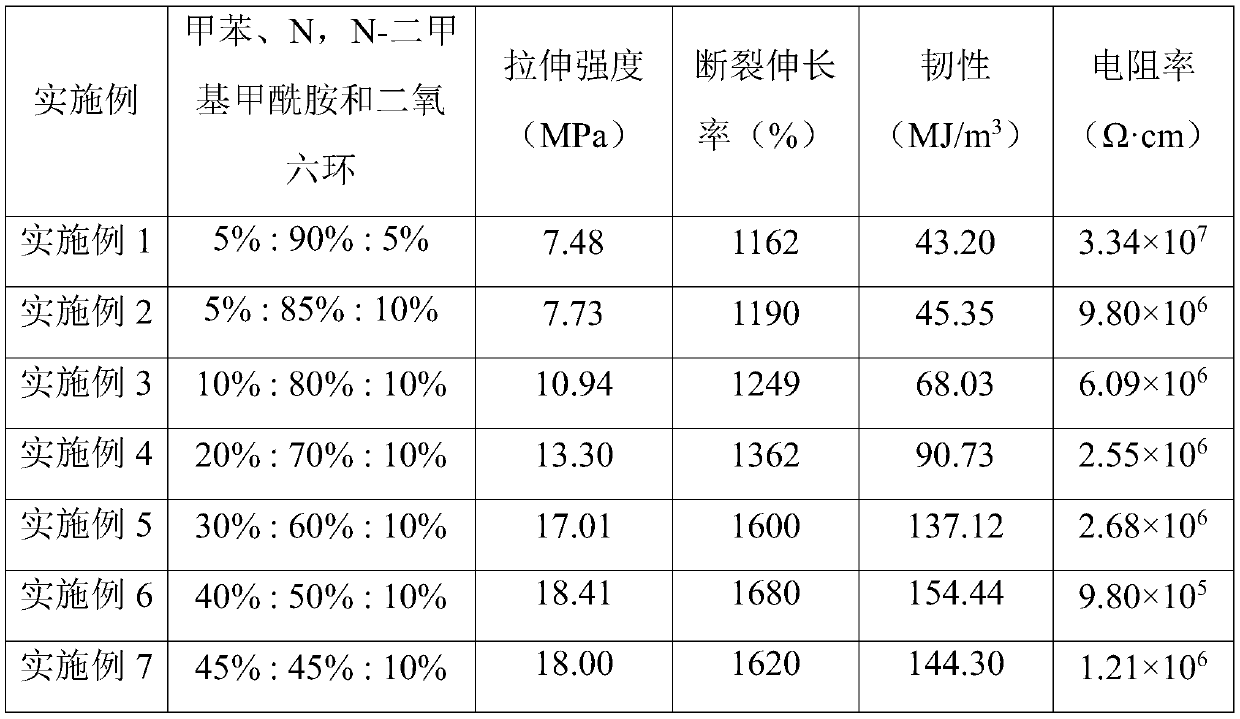

[0042] Embodiment 2~7 provide a kind of preparation method of flexible conductive polyurethane composite film, compare with embodiment 1, difference is to change step (1) in toluene, N,N-dimethylformamide and dioxygen The mass fraction ratio of the hexacyclic ring, the specific mass fraction ratio corresponding to each embodiment and the mechanical and electrical properties of the flexible conductive polyurethane composite film are shown in Table 1.

[0043] Table 1 Mechanical properties and electrical conductivity of composite films obtained under different ratios of toluene, N, N-dimethylformamide and dioxane

[0044]

[0045] It can be seen from Table 1 that the mechanical properties and electrical conductivity of the flexible conductive composite films prepared by using different ratios of ternary mixed solvent systems are quite different. Among them, with the increase of toluene content, the tensile The strength, elongation at break and toughness all showed a trend of in...

Embodiment 8~11

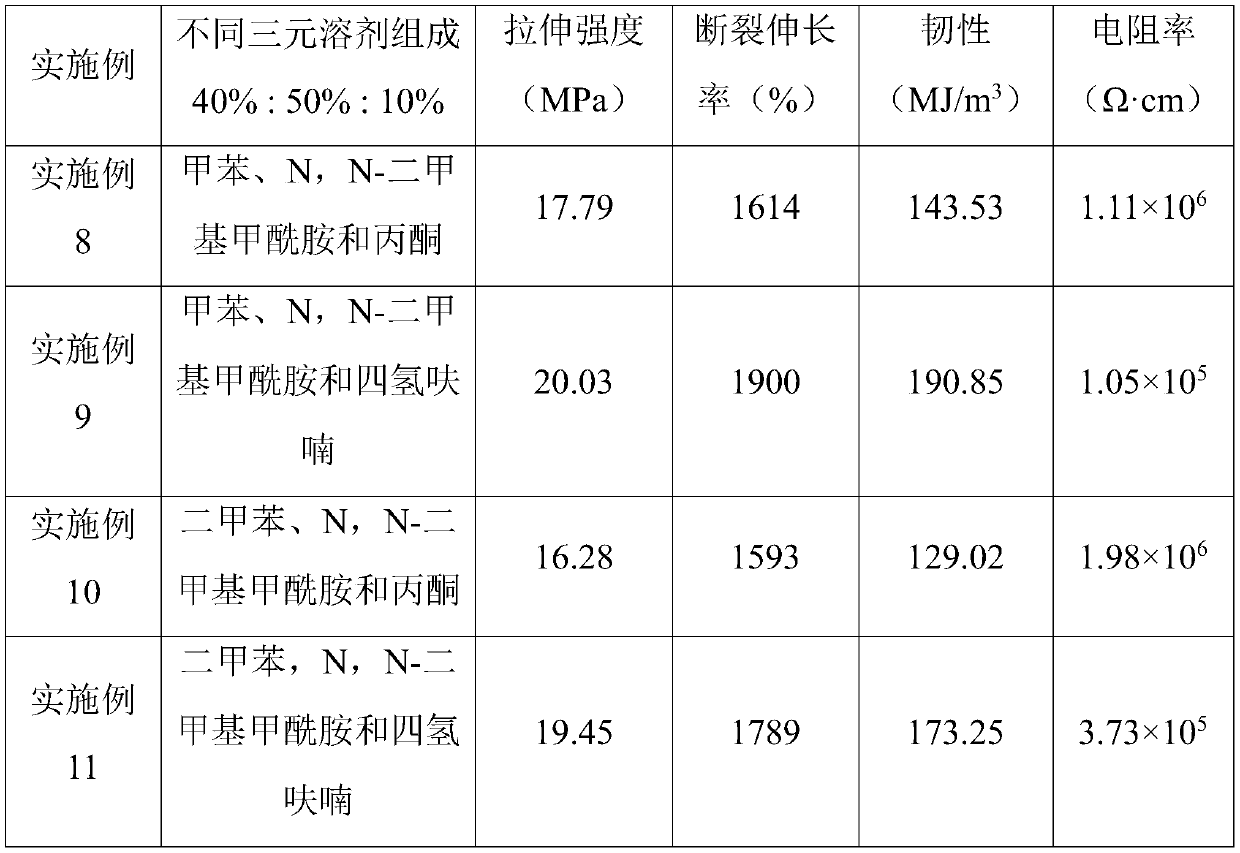

[0047] Embodiments 8 to 11 provide a method for preparing a flexible conductive polyurethane composite film. Compared with Embodiment 6, the difference is that the solvent types in the ternary mixed solvent are changed, and the mass fraction ratio between the solvents is still 40. %: 50%: 10%, the specific solvent composition corresponding to each embodiment and the mechanical properties and the conductive properties of the flexible conductive polyurethane composite film made are as shown in Table 2.

[0048] Table 2 Mechanical properties and electrical conductivity of flexible conductive polyurethane composite films obtained under different solvent compositions

[0049]

[0050] It can be seen from Table 2 that the mechanical properties and electrical conductivity of the flexible conductive composite films prepared by different ternary mixed solvent systems are quite different, and the addition of weaker polar solvents is more conducive to improving the mechanical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com