A phase-change composite material with light-to-heat conversion function and its preparation method

A phase-change composite material and technology of phase-change materials, applied in the field of phase-change composite materials and their preparation, can solve problems such as the lack of mature reports on photothermal conversion advanced energy conversion devices and systems, and achieve excellent photothermal conversion performance and extensive Application prospect, effect of controllable heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

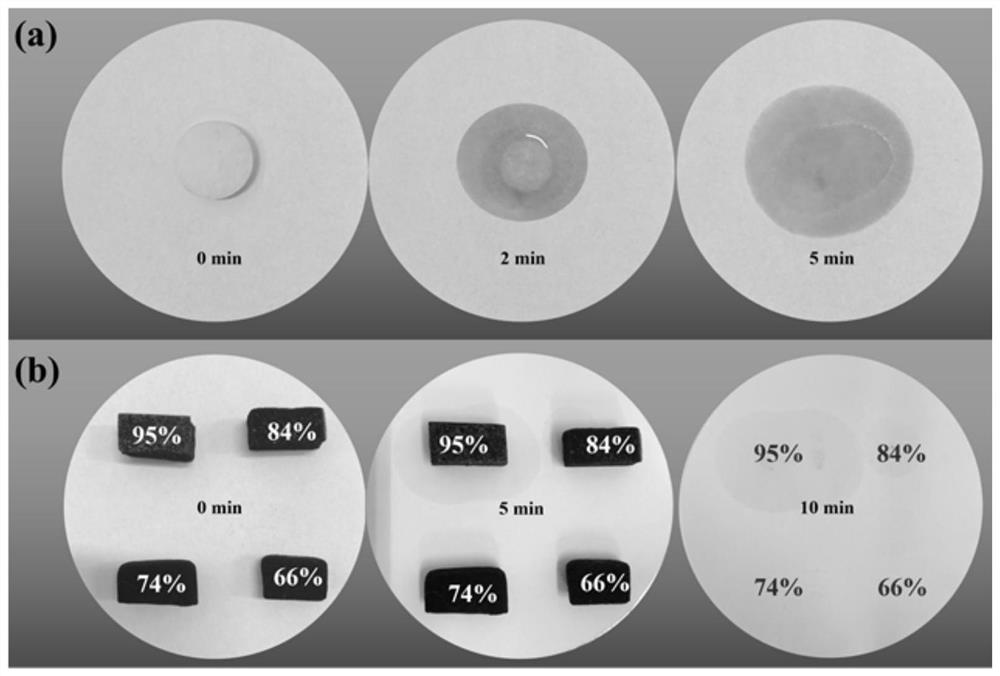

[0050] Example 1 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0051] The specific preparation method is as follows:

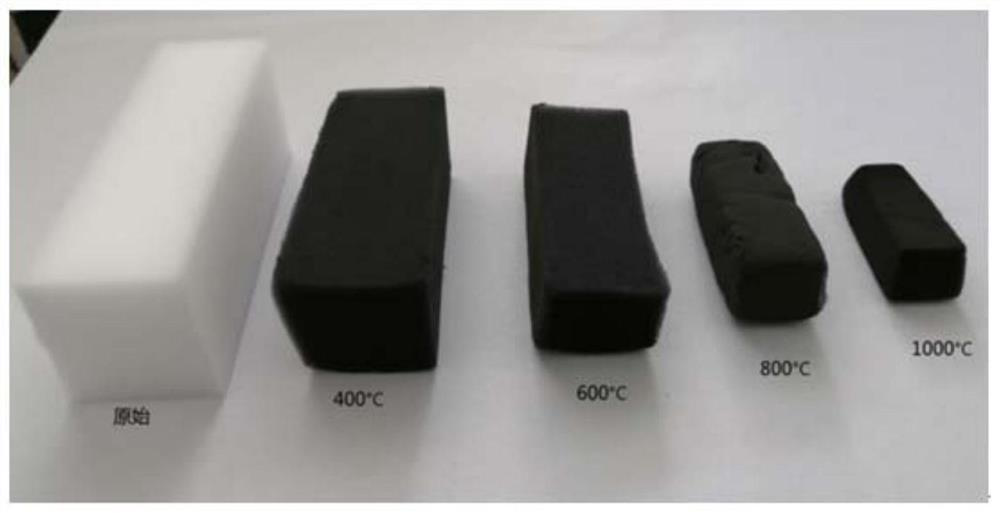

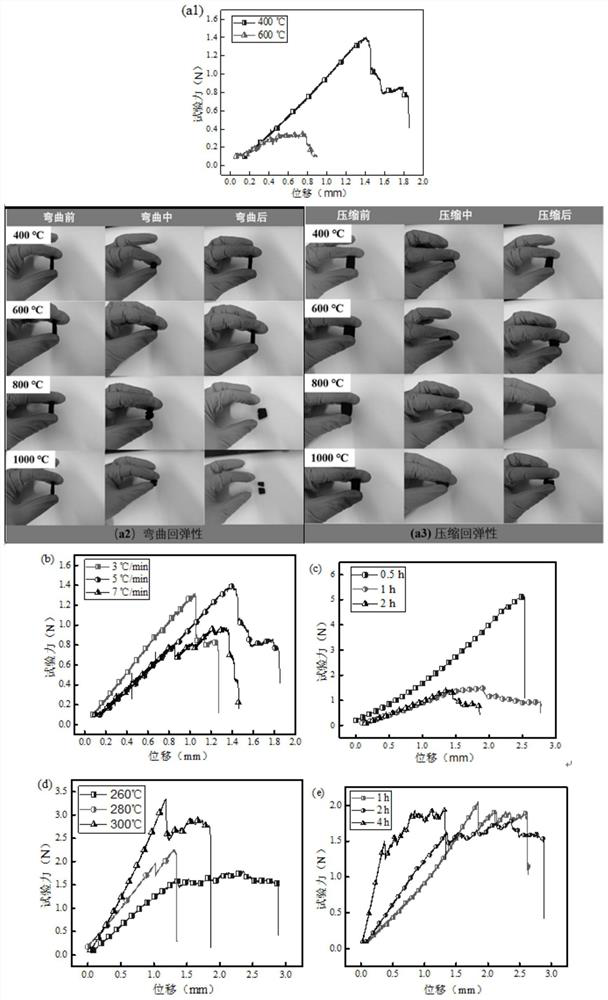

[0052] Preparation of lightweight flexible carbon foam matrix: commercial melamine foam was used as raw material, pre-oxidized and carbonized: the pre-oxidation process was at a temperature of 280°C, and the holding time was 2h; the carbonization process was at 400°C, the holding time was 0.5h, and the heating rate was 5°C / min, to obtain lightweight flexible carbon foam; the density of the resulting carbon foam matrix material is 11.7kg / m 3 , the interior of the matrix is a three-dimensional porous framework connected to each other, and the pore size is 50-200 μm.

[0053] Ti 2 o 3 Nanoparticle modification: Ti 2 o 3 The nanoparticles were mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticles Ti were deposited on the surface of ...

Embodiment 2

[0056] Example 2 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0057] The specific preparation method is as follows:

[0058] The preparation steps of the lightweight flexible carbon foam matrix are the same as in Example 1; secondly, on the basis of the lightweight flexible carbon foam, Ti 2 o 3 Nanoparticles are mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticle Ti is deposited on the surface of the carbon foam skeleton by utilizing the excellent adhesion of polydopamine. 2 o 3 , the nanoparticle specification is the same as in Example 1; the nanoparticle Ti 2 o 3 In the mixed system with Tris solution of dopamine, the concentration of nanoparticles was adjusted to 2.5%. The reaction time of the mixed solution was adjusted to 24 hours in a constant temperature oscillating shaker, and the constant temperature was 30°C.

[0059] Finally, the sol...

Embodiment 3

[0061] Example 3 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0062] The specific preparation method is as follows:

[0063] The preparation steps of the lightweight flexible carbon foam matrix are the same as in Example 1, wherein the pre-oxidation temperature is adjusted to 260°C; secondly, on the basis of the lightweight flexible carbon foam, Ti 2 o 3 The nanoparticles were mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticles Ti were deposited on the surface of the carbon foam skeleton by utilizing the excellent adhesion of PDA. 2 o 3 , the Ti 2 o 3 Nanoparticle specification is the same as embodiment 1; Described nanoparticle Ti 2 o 3 In the mixed system with Tris solution of dopamine, the concentration of nanoparticles was adjusted to 5%. The mixed solution was reacted in a constant temperature shaking shaker for 24 hours, and the constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com