Optical sensing system and sensing testing method

A technology of optical sensing and optical sensor, which is applied in the field of optical sensing technology and sensors, can solve the problems of limited working wavelength range, photoelectric response band of silicon detectors, limited sensing performance of devices, limited sensing sensitivity, etc., and achieves increased The effect of large device operating wavelength range, enhanced detection responsivity, and wide operating wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

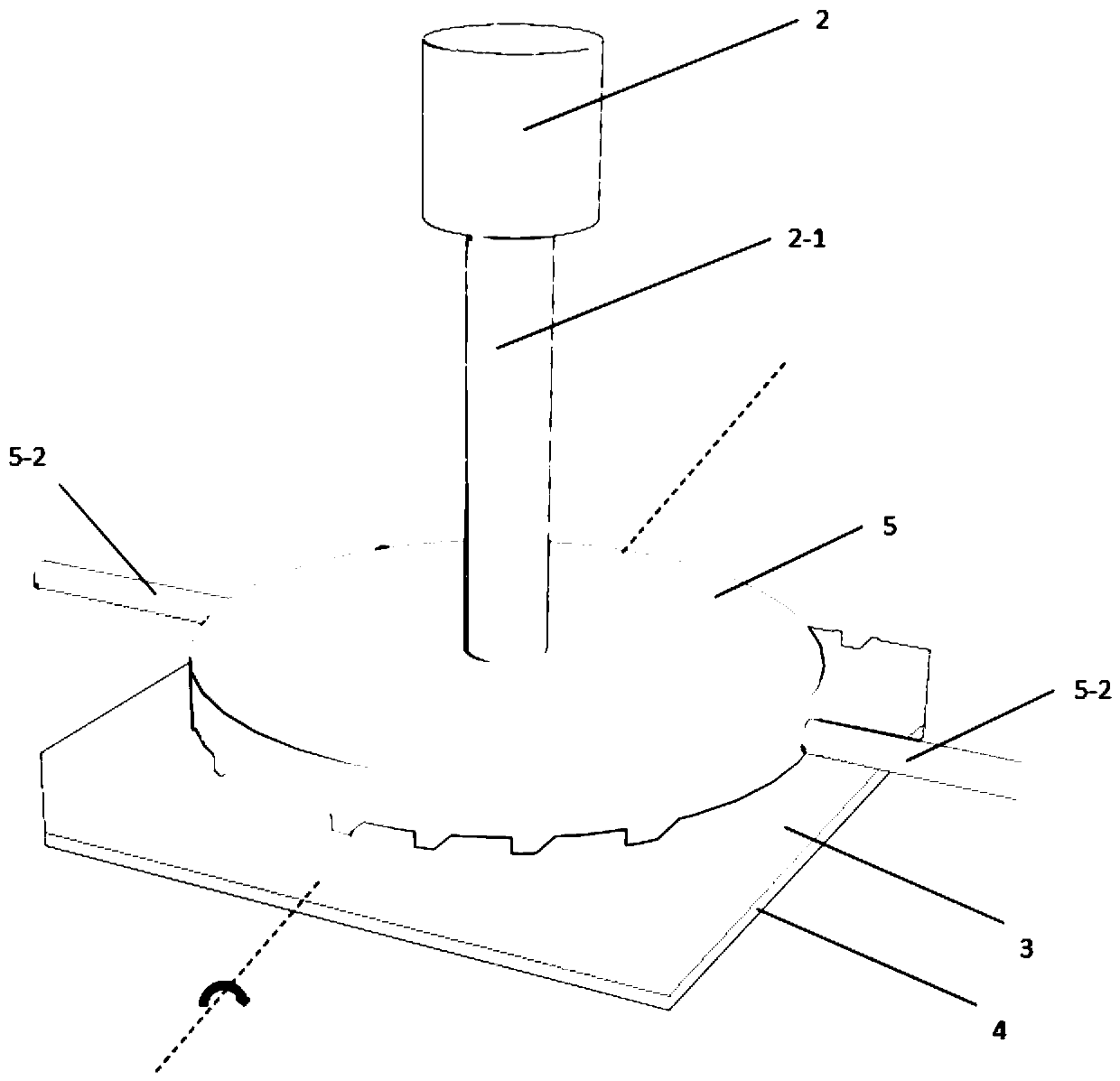

Embodiment 1

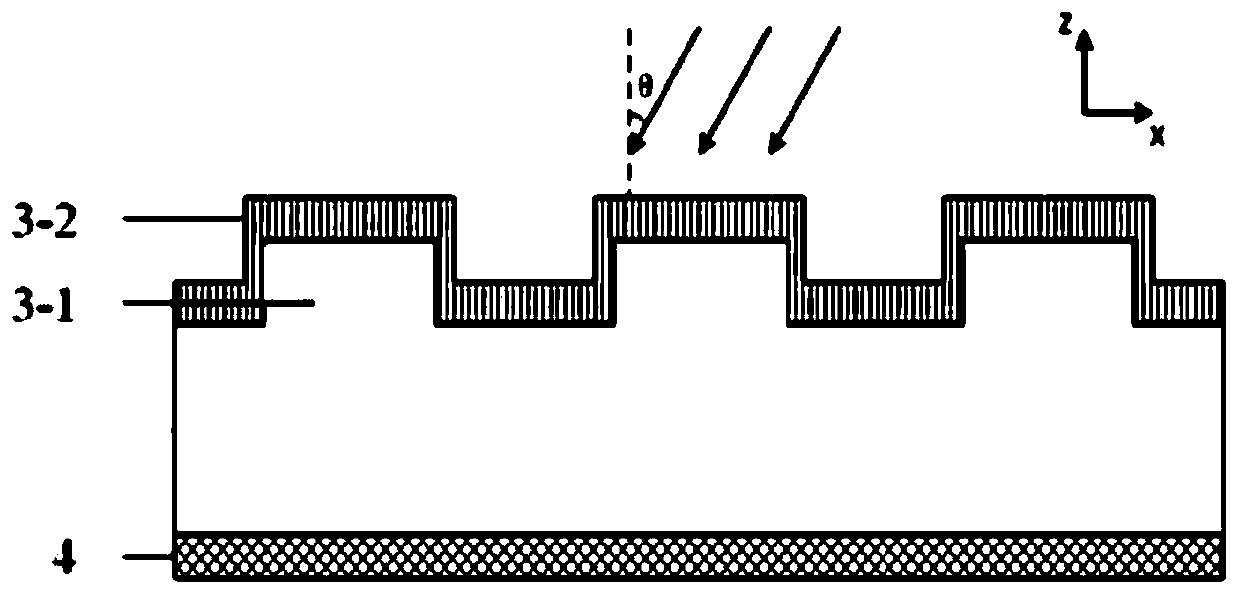

[0063] refer to figure 2 As shown, the first surface of the rotatable silicon wafer facing the monochromatic collimated light source forms a one-dimensional silicon material grating 3-1, wherein the period is 1 micron, the width of the silicon material grating 3-1 is 0.5 micron, and the depth of the silicon material grating is 35 nanometer; a gold film 3-2 is covered on the silicon material grating with a thickness of 50 nanometers. The silicon grating and the gold film together form the grating and form a Schottky junction, and the gold film serves as the first electrode of the photodetector. The second electrode 4 of the photodetector is formed on the second surface of the backlight of the silicon wafer, which is made of gold material and has a thickness of 200 nanometers.

[0064] The incident light of different wavelengths resonates with the surface plasmon wave of the grating 3 at a specific incident angle, and the resonance condition is determined by the following form...

Embodiment 2

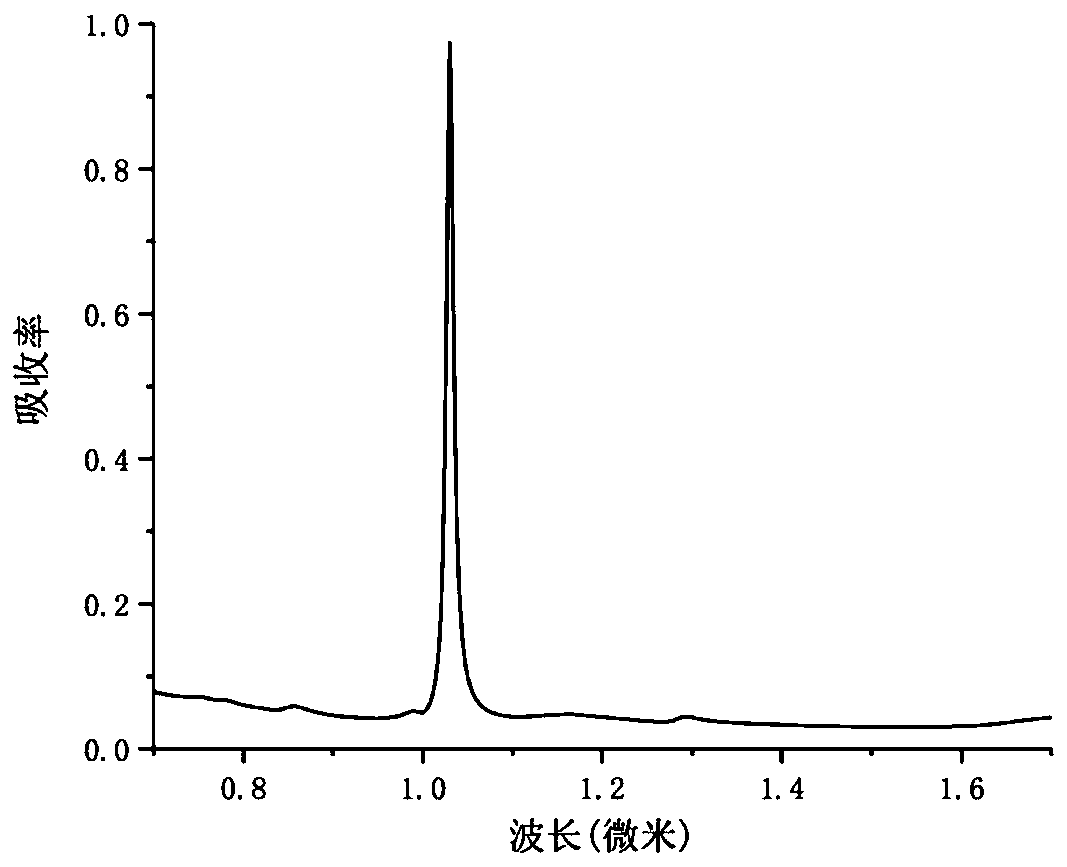

[0073] Figure 14 It is a schematic cross-sectional structure diagram of the photoelectric sensor in the angle-scanning electrical readout optical sensing system of this embodiment. Such as Figure 14 As shown, the preparation of the photodetector in the present embodiment is by covering the gold film on the surface of the rotating silicon wafer, and then forming a silicon dioxide grating 3-3 on the gold film, wherein the gold film thickness is 80 nanometers, and the silicon dioxide grating depth is 155 nm and the width is 360 nm. Figure 15 It is the calculation result of the absorption spectrum of the angle-scanning electrical readout optical sensing system of this embodiment under normal incident light irradiation. The resonance occurs at a wavelength of 1068 nm, the absorption at the peak is about 98%, the full width at half maximum is Figure 16 As shown, when the refractive index changes from 1 to 1.01, the resonance peak changes from 1068 nm to 1077 nm, and the sensit...

Embodiment 3

[0075] Figure 17 It is a schematic diagram of the photodetector in the electrical readout optical sensing system of the two-dimensional grating angular scanning of the present embodiment. In this embodiment, the photodetector is prepared by covering the surface of the rotating silicon wafer with a gold film, and then forming a gold two-dimensional disk array 3-4 on the gold film. The thickness of the gold film is 80 nanometers, the height of the two-dimensional gold disk array is 100 nanometers, the radius is 500 nanometers, and the disk period is 1400 nanometers. Figure 18 It is the calculation result of the absorption spectrum of the angle-scanning electrical readout optical sensing system of this embodiment under normal incident light irradiation. Resonance between incident light and surface plasmon waves occurs at 1412 nm at normal incidence. The absorption at the peak is greater than 98%, and the full width at half maximum is 4 nm. The quality factor Q is as high as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Divergence angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com