Surface coated and modified lithium lanthanum zirconium oxygen-based solid electrolyte material and preparation method and application thereof

A technology of solid electrolyte, lithium lanthanum zirconium oxide, which is applied in the field of lithium lanthanum zirconium oxide solid electrolyte material and its preparation, can solve the problems of safety restrictions on lithium ion batteries, increased charge and discharge polarization, and poor interface contact. Achieve the effects of broadening the application range, alleviating volume deformation, and improving surface chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the surface-coated modified lithium-lanthanum-zirconium-based solid electrolyte material comprises:

[0036] (1) Preparation of the lithium lanthanum zirconium oxide solid electrolyte (LLZO);

[0037] The preparation method of lithium lanthanum zirconium oxide solid electrolyte (LLZO) is a sol-gel method, and the preparation steps include: the precursors of lithium Li, lanthanum La, zirconium Zr and doping element M are prepared according to the formula of Li, La, Zr, M The molar ratio is (5+x): 3:x:(2-x) mixing, adding a solvent to dissolve, adding a precipitating agent to form a sol-gel, heating and evaporating the solvent to obtain a mixed powder; grinding the mixed powder, first in Sintering at 250-600° C. for 2-48 hours, grinding again, and sintering at 500-1000° C. for 2-48 hours to obtain the lithium lanthanum zirconium oxide solid electrolyte (LLZO).

[0038] Alternatively, the preparation method of the lithium lanthanum zirconium oxid...

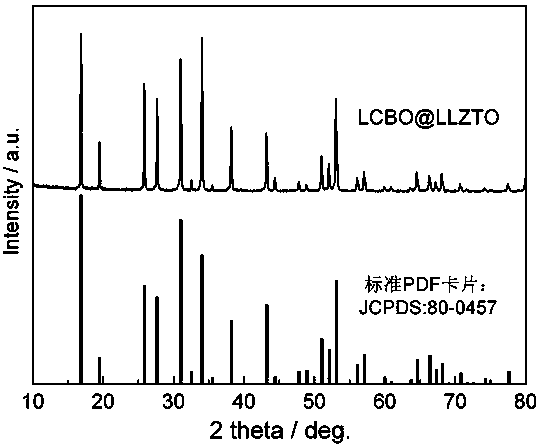

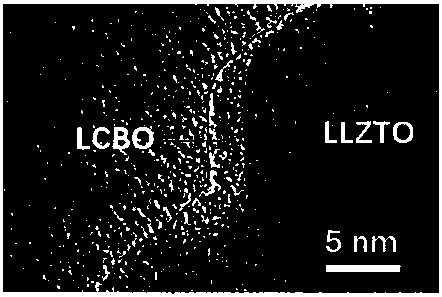

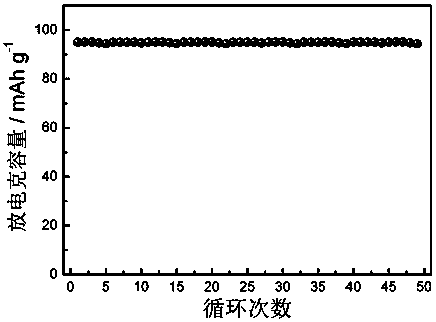

Embodiment 1

[0043] (1) The chemical formula is Li prepared by solid-state reaction method 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Lithium-lanthanum-zirconium-based solid electrolyte powder, the preparation steps of which include: selecting LiOH, La 2 o 3 , ZrO 2 and Ta 2 o 5 LiOH is used as a raw material with an excess of 10 wt% LiOH, which is ball-milled in alcohol for 24 hours and then dried; then calcined at 900°C for 10 hours with a heating rate of 4°C / min, and after the sintering is completed, the powder is crushed and sieved to obtain Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Powder (LLZTO).

[0044] (2) Dry and sieve the LLZTO powder for pretreatment, then place the pretreated LLZTO powder in the chemical vapor deposition reaction chamber, evacuate the reaction chamber to 5Pa, and preheat to the coating temperature of 800°C; The cladding material is oxide glass solid electrolyte 0.5Li 2 CO 3 0.5 Li 3 BO 3 (LCBO), heat its precursor to 100°C, the reaction chamber starts to rotate, ...

Embodiment 2

[0050] (1) The chemical formula is Li prepared by solid-state reaction method 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Lithium-lanthanum-zirconium-based solid electrolyte powder, the preparation steps of which include: selecting LiOH, La 2 o 3 , ZrO 2 and Ta 2 o 5 LiOH is used as a raw material with an excess of 10 wt% LiOH, which is ball milled in alcohol for 24 hours and then dried; then calcined at 900 °C for 10 hours with a heating rate of 4 °C / min, and after the sintering is completed, the powder is crushed and sieved to obtain Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Powder (LLZTO), which is sieved to obtain LLZTO powder with uniform particle size.

[0051] (2) Dry and sieve the LLZTO powder for pretreatment, then place the pretreated LLZTO powder in the chemical vapor deposition reaction chamber, evacuate the reaction chamber to 5 Pa, and preheat to the coating temperature of 700 °C ; The precursor of the cladding layer material is a sulfide glass solid electrolyte Li 2 S-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com