A kind of garbage fly ash heavy metal stabilizer and using method thereof

A heavy metal stabilizer, garbage fly ash technology, applied in the restoration of polluted soil and other directions, can solve the problems of poor effect, poor dissolution rate of heavy metal substances, poor heavy metal effect, etc., and achieves high treatment efficiency, enhanced surface activity, and chelation. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A garbage fly ash heavy metal stabilizer of the present embodiment comprises the following raw materials in parts by weight: 5 parts of phosphate compounds, 2 parts of light-burned magnesium oxide, 1 part of mercapto-type chelating agent, 1 part of thiuram, modified sodium base 1 part of bentonite, 1 part of homogenate;

[0026] The preparation method of homogenizing agent is: add acetone solution into the reaction kettle, then add dodecyl glucoside, stir at a speed of 100r / min for 35min, then add trehalose, and stir at a speed of 200r / min 10min, finally add chitosan, stir at a speed of 350r / min for 5min, and finally homogenize for 60min under the condition of 5MPa.

[0027] The phosphate compound in this embodiment is prepared by mixing orthophosphate and condensed phosphate in a weight ratio of 3:1.

[0028] The orthophosphate in this embodiment is trisodium phosphate.

[0029] The condensed phosphate in this embodiment is pyrophosphate.

[0030] The preparation me...

Embodiment 2

[0040] A garbage fly ash heavy metal stabilizer of the present embodiment comprises the following raw materials in parts by weight: 7 parts of phosphate compounds, 5 parts of light-burned magnesium oxide, 3 parts of mercapto-type chelating agents, 3 parts of thiuram, modified sodium base 3 parts of bentonite, 2 parts of uniform adjustment;

[0041] The preparation method of the homogenizer is: add acetone solution into the reaction kettle, then add dodecyl glucoside, stir at a speed of 200r / min for 45min, then add trehalose, and stir at a speed of 300r / min 20min, finally add chitosan, stir at a speed of 450r / min for 15min, and finally homogenize for 100min under the condition of 10MPa.

[0042] The phosphate compound in this embodiment is prepared by mixing orthophosphate and condensed phosphate in a weight ratio of 3:1.

[0043] The orthophosphate in this embodiment is dibasic sodium phosphate.

[0044] The condensed phosphate in this embodiment is pyrophosphate.

[0045] ...

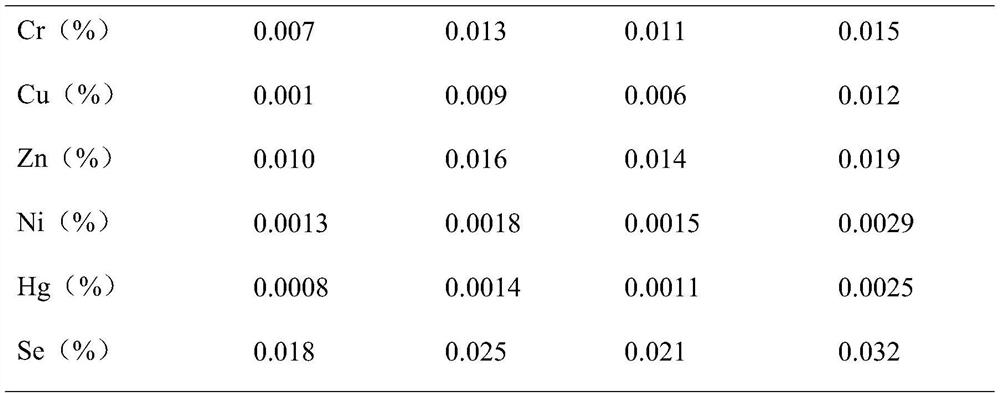

Embodiment 3

[0055] A garbage fly ash heavy metal stabilizer of the present embodiment comprises the following raw materials in parts by weight: 6 parts of phosphate compounds, 3.5 parts of light-burned magnesium oxide, 2 parts of mercapto-type chelating agents, 2 parts of thiuram, modified sodium base 2 parts of bentonite, 1.5 parts of uniform adjustment;

[0056] The preparation method of homogenizing agent is: add acetone solution into the reaction kettle, then add dodecyl glucoside, stir at a speed of 150r / min for 40min, then add trehalose, and stir at a speed of 250r / min 15min, finally add chitosan, stir at a speed of 400r / min for 10min, and finally homogenize under the condition of 7.5MPa for 80min.

[0057] The phosphate compound in this embodiment is prepared by mixing orthophosphate and condensed phosphate in a weight ratio of 3:1.

[0058] The orthophosphate of the present embodiment is dipotassium hydrogen phosphate.

[0059] The condensed phosphate in this embodiment is metap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com