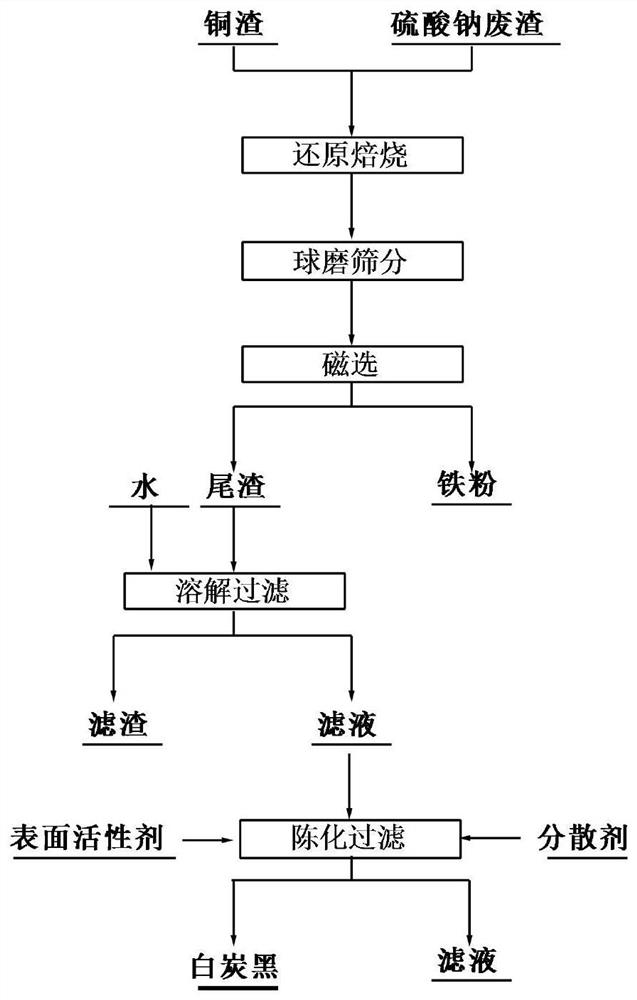

A method for synergistic resource utilization of copper slag and sodium sulfate waste slag

A sodium sulfate, resource-based technology, applied in the direction of silicon oxide, silicon dioxide, process efficiency improvement, etc., can solve the problems of difficulty in bulk consumption and treatment, high site requirements, easy to absorb water and deliquescence, etc., and achieve technical operability The effect of strong, heavy metal grade improvement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

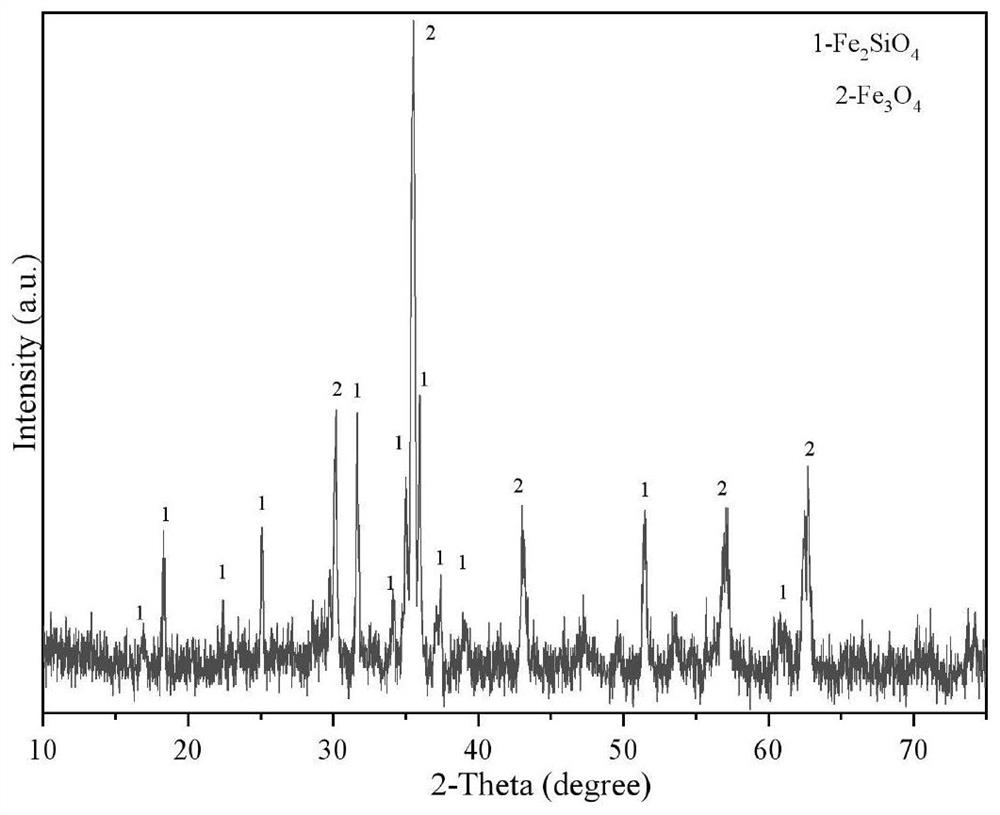

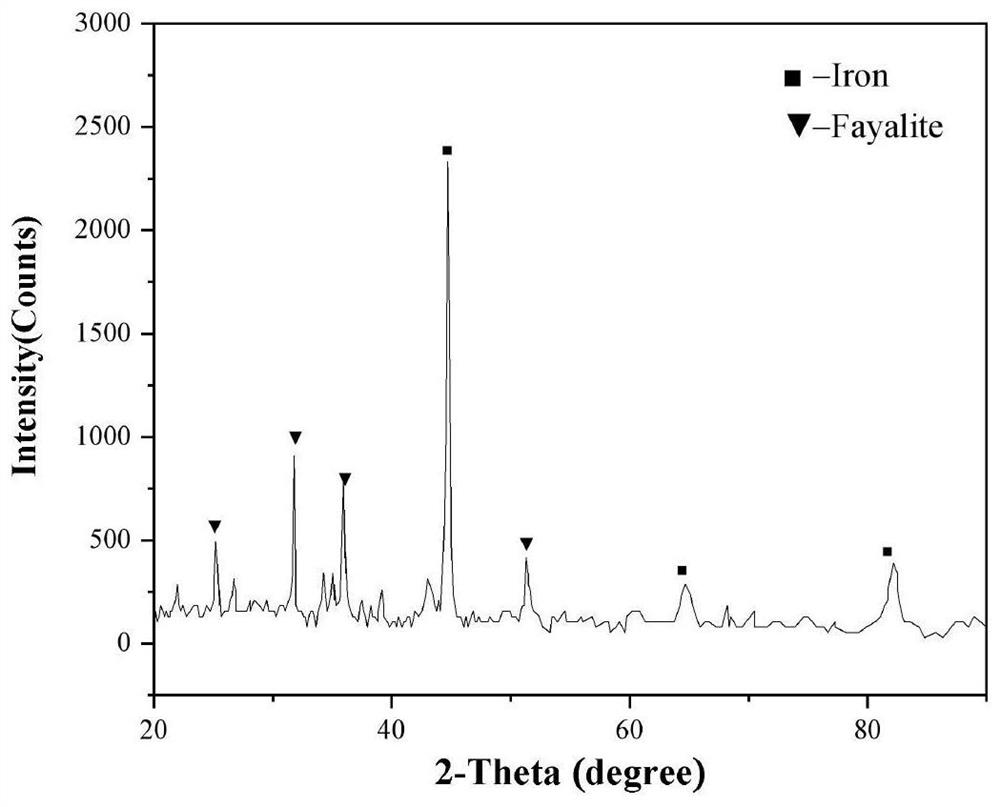

[0047] First, 1kg copper slag ball milling and over 200 mesh sieves, according to the mass ratio of 1: 1 and sodium sulfate waste residue, at a CO atmosphere and 1000 ° C for 120 min; after the reaction is completed, the calcination product is removed, and the sieve is broken. Magnetic selection, magnetic selection in 1200 g of field, to obtain iron powder, iron powder XRD analysis image 3 . Magnetic selection tailings were poured into 1.5L water and stirred after a certain time after a certain period of time; gave about 1.2 l of the filtrate 720 min at 50 ° C, and then the water bath was warmed to 80 ° C; and the 120 ml concentration of 10 wt% dispersant NaCl was added to the water bath. The 120 ml concentration is 70 wt% surfactant n-butanol; the resulting solution is stirred, and the concentration of 5 wt% sulfuric acid is added dropwise, and the pH is adjusted to 8 ~ 9, and the constant temperature of 80 ° C is filtered after 180 min. Water repeatedly rinsed - 6 times, then d...

Embodiment 2

[0049] First, 1kg copper slag ball mill and over 200 mesh sieve were first, according to the mass ratio 2: 1 and sodium sulfate waste residue, 60 min was charged at 900 ° C; after the end of the reaction, the calcined product was taken out, and the sieve was broken. The selection machine, magnetic option is performed on 1200 g of field, to obtain iron powder, magnetic selection tailings poured into 1.5L water to stir after a certain time after a certain period of time; to get about 1.2L filtrate 900 min at 60 ° C, then heated to 70 ° C; 120 ml of concentration of 15 wt% dispersant NaCl, 100 ml of concentration of 80 wt% surfactant NaCl is added, and then the resulting solution is stirred, and the concentration is added to 8 wt% sulfuric acid, adjusting the pH to 8 ~ 9. Keep 50 ° C constant temperature aging 240 min after filtration; filter residue repeatedly rinsed with deionized water - filtration 5 times, then the filter residue dries at a temperature of 90 ° C to obtain white c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com