Flexible geopolymer-based anticorrosive paint and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

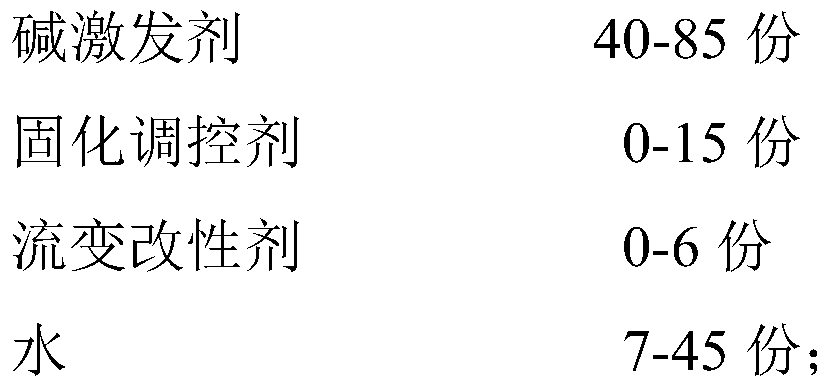

Method used

Image

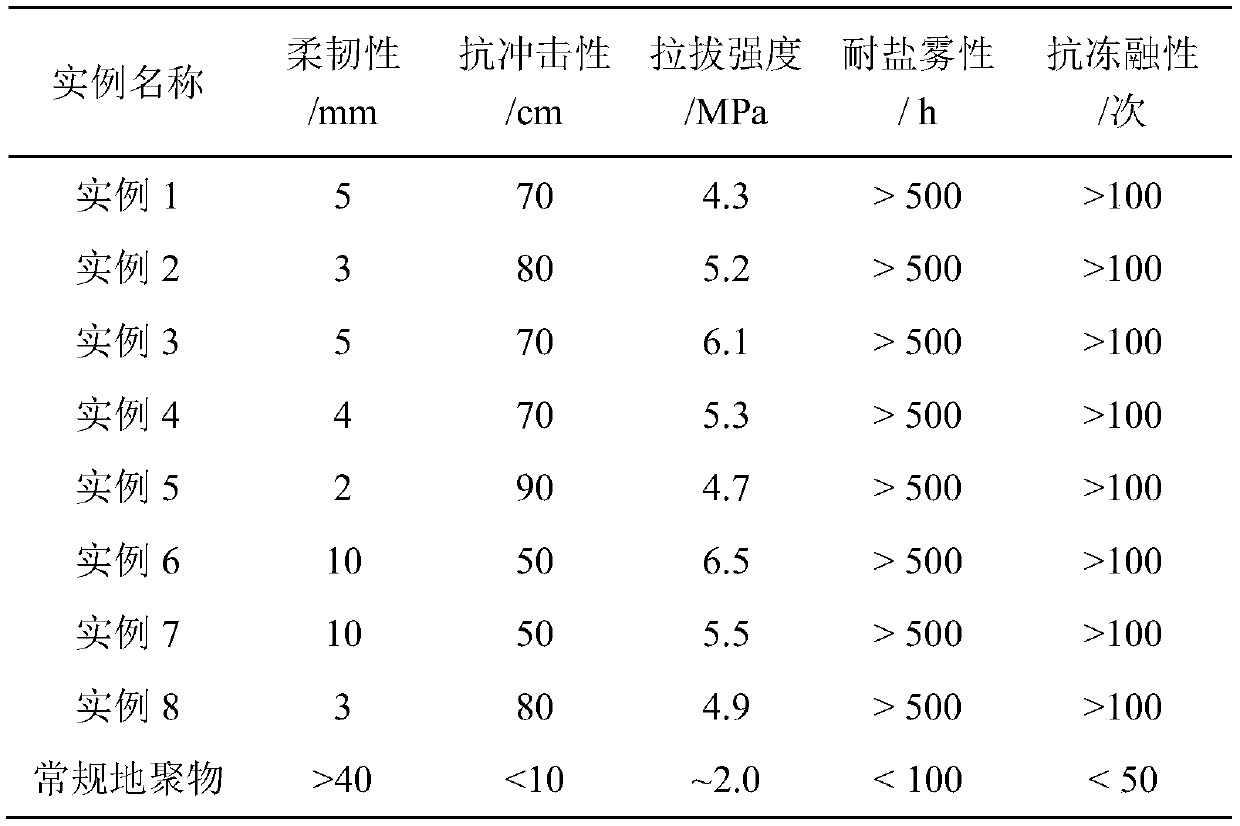

Examples

Embodiment 1

[0037] (1) Mix 30 parts of diatomaceous earth, 5 parts of titanium dioxide, 1 part of carbon black, 20 parts of talcum powder, and 44 parts of micaceous iron oxide to obtain component A;

[0038] (2) 85 parts of sodium silicate with a modulus of 3.3, 2.5 parts of curing regulator potassium hydroxide, 5.5 parts of rheology modifier bentonite, and 7 parts of water are uniformly mixed to obtain component B;

[0039] (3) Mix 50 parts of diphenyldiethoxysilane, 30 parts of phenyltrimethoxysilane and 20 parts of tetraethyl orthosilicate to obtain component C;

[0040] (4) Stir with a high-speed disperser, slowly add 52 parts by weight of component A to 28 parts by weight of component B, and then continue to add 20 parts by weight of component C to obtain a flexible geopolymer-based anti-corrosion coating.

Embodiment 2

[0042] (1) Mix 30 parts of fly ash, 35 parts of diatomaceous earth, 2 parts of iron red, 10 parts of heavy calcium carbonate, and 23 parts of glass flakes to obtain component A;

[0043] (2) 55 parts of sodium silicate with a modulus of 2.5, 3 parts of curing regulator calcium hydroxide, 0.5 part of rheology modifier fumed silica, and 41.5 parts of water are mixed uniformly to obtain component B;

[0044] (3) Mix 40 parts of methyltrimethoxysilane, 45 parts of phenyltriethoxysilane and 15 parts of octadecyltrimethoxysilane to obtain component C;

[0045] (4) Stir with a high-speed disperser, slowly add 27 parts by weight of component A to 15 parts by weight of component B, and then continue to add 58 parts by weight of component C to obtain a flexible geopolymer-based anti-corrosion coating.

Embodiment 3

[0047] (1) Mix 15 parts of kaolin, 5 parts of titanium dioxide, 1 part of carbon black, 30 parts of talcum powder, and 49 parts of quartz powder to obtain component A;

[0048] (2) 64 parts of modulus are 1.7 sodium water glass, 5 parts of curing regulator sodium hydroxide, 3 parts of rheology modifier polyamide wax, 3 parts of rheology modifier xanthan gum, 25 parts of water mix Obtain B component evenly;

[0049] (3) Mix 60 parts of methylphenyldimethoxysilane and 40 parts of butyltrimethoxysilane evenly to obtain component C;

[0050] (4) Use a high-speed disperser to stir, slowly add 60 parts by weight of A component to 28 parts by weight of B component, and then continue to add 12 parts by weight of C component to obtain a flexible geopolymer-based anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com