A novel high-potential multi-layer carbon-coated polyanion sodium-ion battery cathode material and preparation method thereof

A polyanionic, sodium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of expensive organic solvents, uneven mixing of raw materials, uncontrollable intermediate processes, etc., and achieve high discharge capacity and rate performance. , The effect of good product consistency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

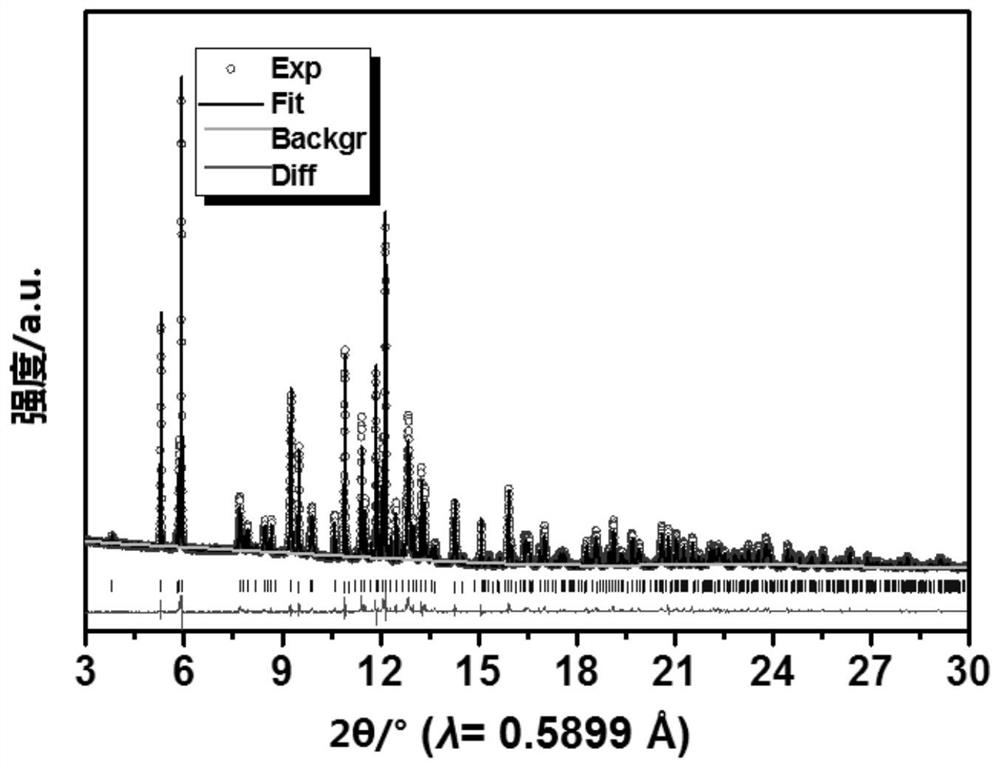

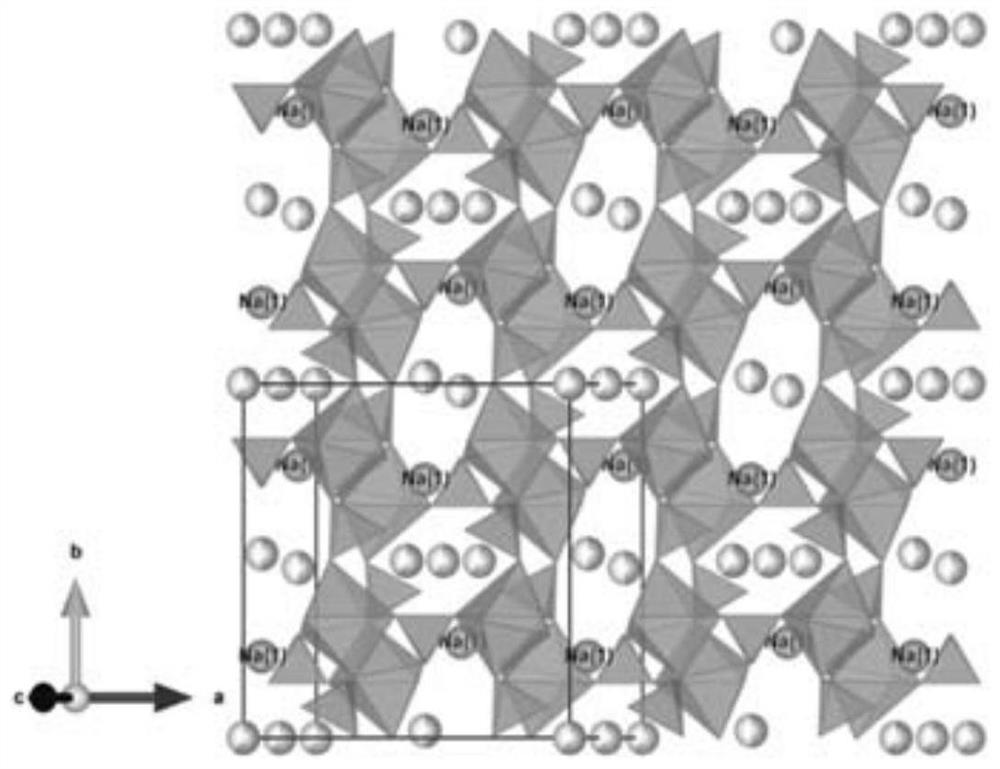

Embodiment 1

[0060] In the present embodiment, the technology of the preparation method is as follows:

[0061] A, according to the chemical formula Na 2 Fe 2 (SO 4 ) 3 ratio, weigh anhydrous Na 2 SO 4 1mol (analytical purity, purity>99.5%) 142.75g and anhydrous FeSO 4 2mol (analytical purity, purity>99.0%) 307.07g, stearic acid (analytical purity, purity>99%) 86.20g (0.3mol), ascorbic acid (analytical purity, purity>99%) 30.90g (5wt%), ethanol (Analytical pure, purity>99.5%) 35ml as grinding aid. Then, it was added to a sanding jar containing zirconia sanding beads (3.09 kg, with a material ratio of 5:1), and then the sanding jar was placed in a glove box and protected with argon as an inert atmosphere to complete the assembly. The set speed is 800 rpm, and the total running time is 18h.

[0062] B. Drying of the precursor powder

[0063] The rheological phase material obtained in step A was placed in a drying oven under the protection of an argon atmosphere, and dried at 60° C...

Embodiment 2

[0073] In the present embodiment, the technology of the preparation method is as follows:

[0074] A, according to the chemical formula Na 1.5 Fe 2.25 (SO 4 ) 3 ratio, weigh anhydrous Na 2 SO 4 0.75mol (analytical purity, purity>99.5%) 107.06g and anhydrous FeSO 4 2.25mol (analytical purity, purity>99.0%) 345.45g, citric acid (analytical purity, purity>99%) 57.6g (0.3mol), ascorbic acid (analytical purity, purity>99%) 18.54g (3wt%), acetone (Analytical pure, purity>99.5%) 35ml as grinding aid. Then, it was added to a sanding jar containing zirconia sanding beads (4.82 kg, with a material ratio of 10:1), and then the sanding jar was placed in a glove box and protected with argon as an inert atmosphere to complete the assembly. The set speed is 1200 rpm, and the total running time is 12h.

[0075] B. Drying of the precursor powder

[0076] The rheological phase material obtained in step A was placed in a drying oven under the protection of an argon atmosphere, and dri...

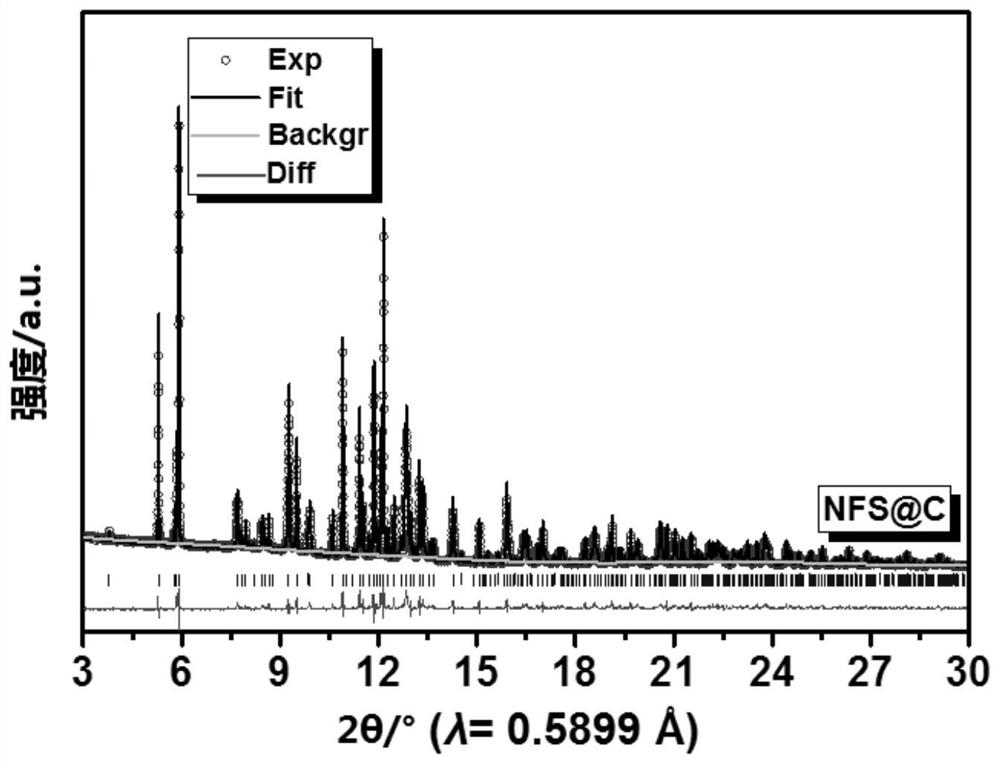

Embodiment 3

[0086] In the present embodiment, the technology of the preparation method is as follows:

[0087] A, according to the chemical formula Na 1.75 Fe 2.125 (SO 4 ) 3 ratio, weigh anhydrous Na 2 SO 4 0.875mol (analytical purity, purity>99.5%) 124.91g and anhydrous FeSO 4 2.125mol (analytical purity, purity>99.0%) 326.26g, sucrose (analytical purity, purity>99%) 102.69g (0.3mol), ascorbic acid (analytical purity, purity>99%) 18.7g (4wt%), ethylene glycol Alcohol (analytical grade, purity>99.5%) 35ml was used as grinding aid. Then, it was added to a sanding jar containing zirconia sanding beads (3.49 kg, with a material ratio of 7.5:1), and the sanding jar was placed in a glove box and protected with argon as an inert atmosphere to complete the assembly. The set speed is 1000 rpm, and the total running time is 15h.

[0088] B. Drying of the precursor powder

[0089] The rheological phase material obtained in step A was placed in a drying oven under the protection of an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com