Polyurethane coating for mobile phone back shell and preparation method and application method thereof

A technology of polyurethane coatings and application methods, which is applied in the field of polyurethane coatings for mobile phone shells and its preparation, and can solve problems such as flying debris sticking to plates, mobile phone back shells easily sticking to dust, and coatings without antistatic properties. Achieve the effects of not easy to decompose and fail, excellent antibacterial and antistatic properties, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

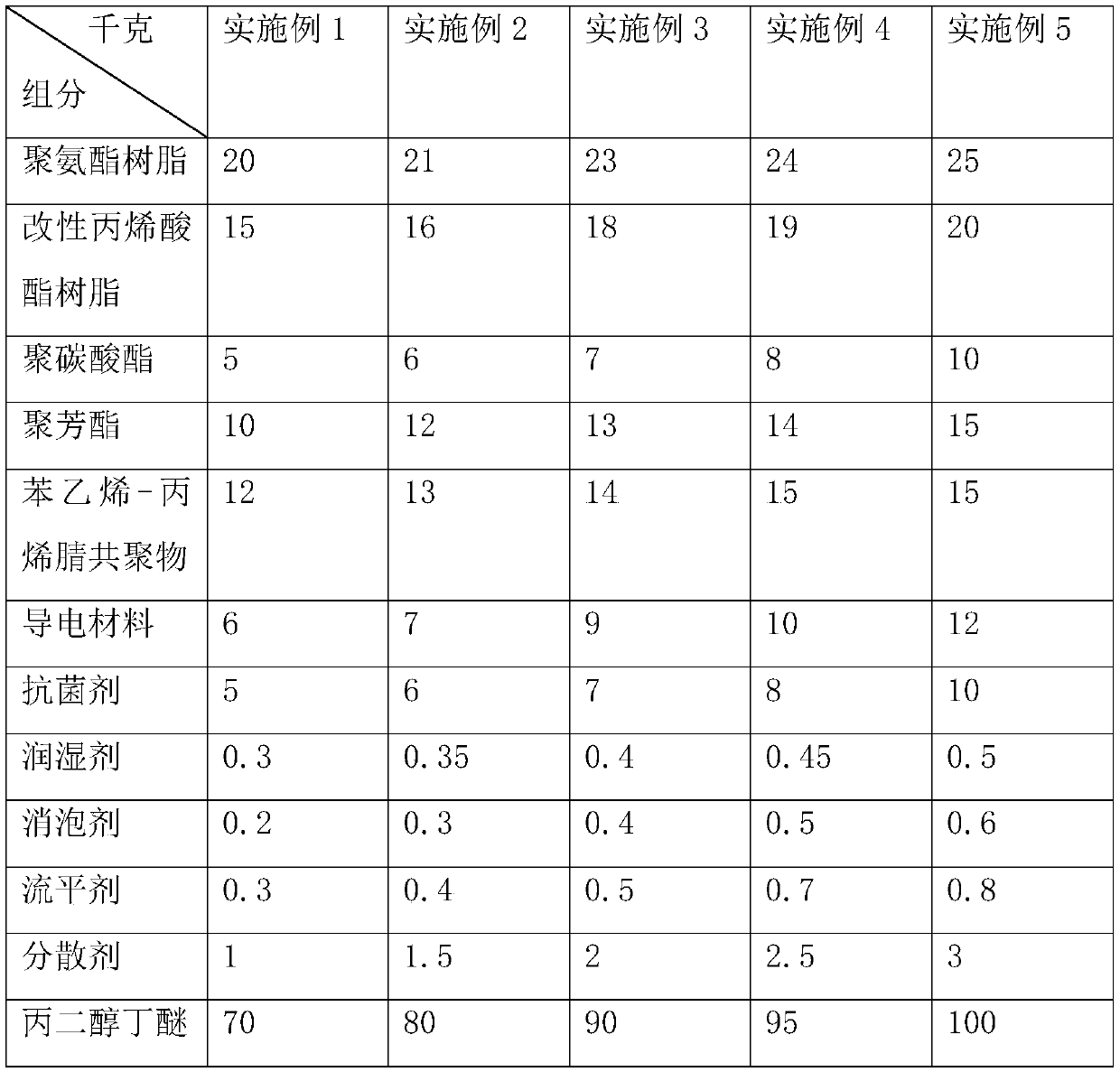

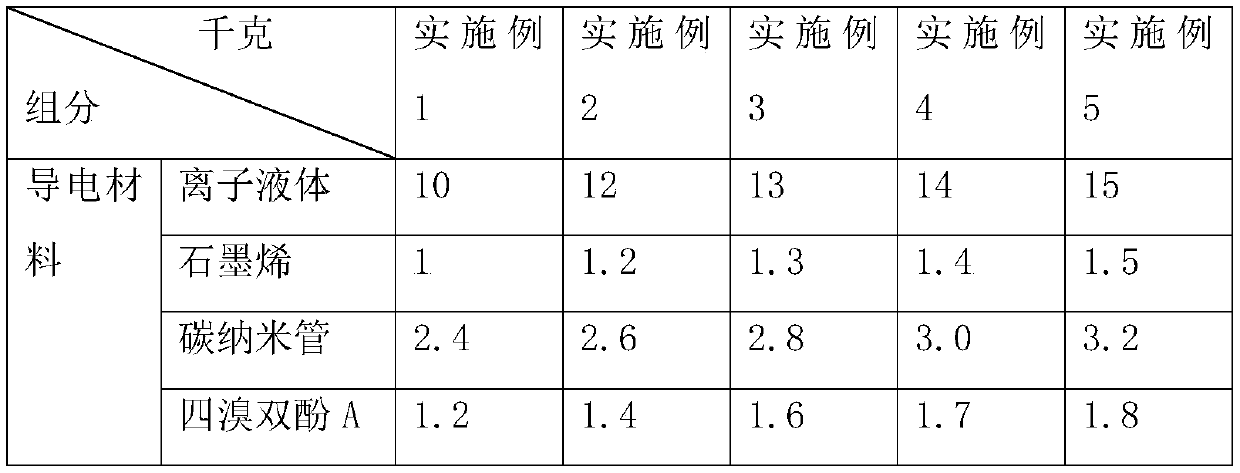

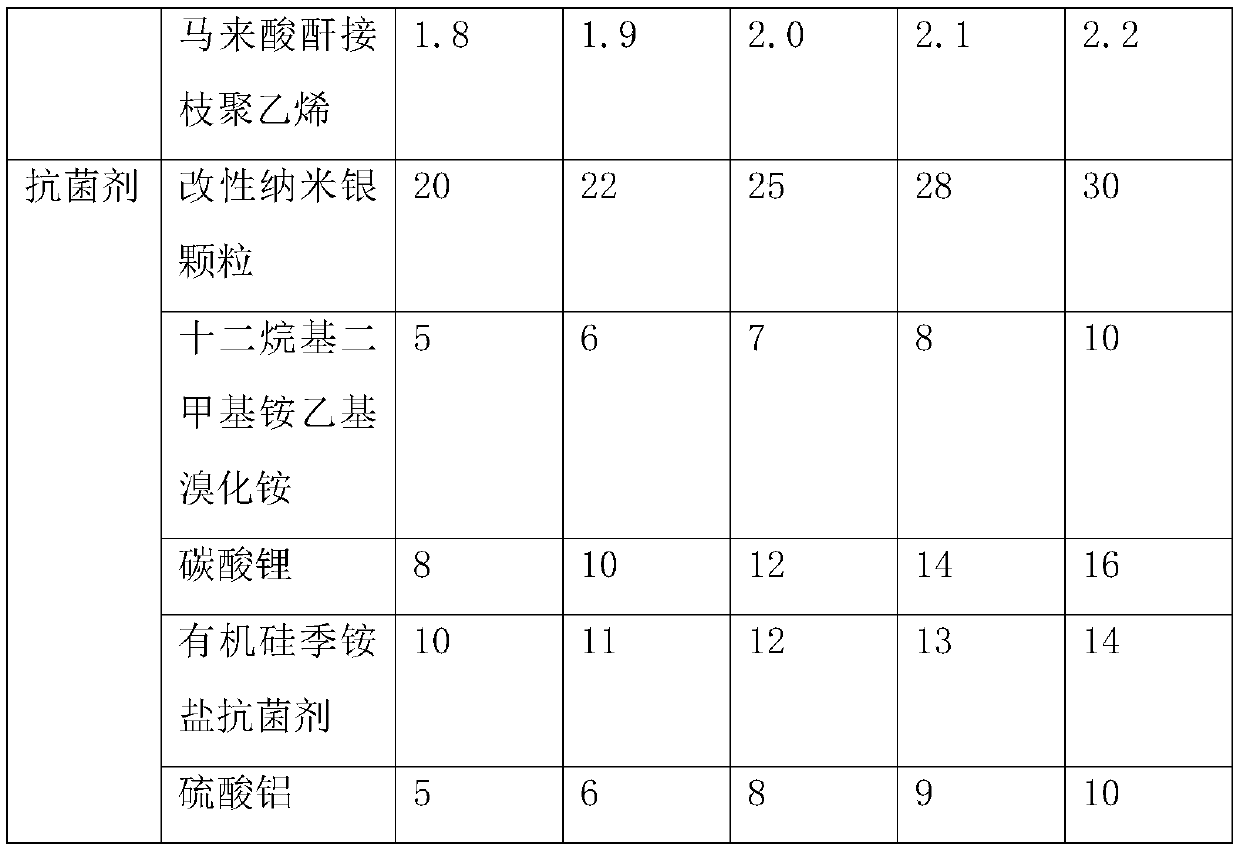

Method used

Image

Examples

preparation example 1-3

[0048] In Preparation Example 1-3, the cysteine was selected from the cysteine sold by Henan Yankang Food Additive Co., Ltd. with the product number 1011, and the trishydroxymethylaminomethane was selected from the product number 01 sold by Guangzhou Hongcheng Biotechnology Co., Ltd. of trishydroxymethylaminomethane.

preparation example 1

[0049] Preparation example 1: (1) Decoct clove leaves and water with a weight ratio of 1:6 twice, combine the water decoction, concentrate under reduced pressure to make a concentrated solution with a relative density of 1, and add a concentrated solution with a volume ratio of 8.5 : 10 of 3,4-dihydroxyphenethyl alcohol, mix well, leave standstill for 20h, get the supernatant;

[0050] (2) Add 40kg silver nitrate powder and 40kg cysteine to 100kg water, stir for 1h, suction filter, add the supernatant obtained in step (1), mix well, add 20kg tris and 10kg sodium borohydride , aged, adjusted pH, centrifuged, washed three times with deionized water, and dried at 40°C to prepare modified nano-silver particles.

preparation example 2

[0051] Preparation example 2: (1) Decoct clove leaves and water with a weight ratio of 1:8 twice, combine the decoctions, concentrate under reduced pressure to make a concentrated solution with a relative density of 1.1, and the volume ratio of the addition to the concentrated solution is 8.7 : 10 of 3,4-dihydroxyphenethyl alcohol, mix well, leave standstill for 22h, get the supernatant;

[0052] (2) Add 50kg of silver nitrate powder and 45kg of cysteine to 130kg of water, stir for 1.5h, filter with suction, add the supernatant obtained in step (1), mix well, add 25kg of tris and 15kg of hydroboration Na, aging, adjusting pH, centrifuging, washing with deionized water for 4 times, and drying at 43°C to obtain modified nano-silver particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com