Medical metal titanium or titanium alloy surface composite anticorrosive coating and preparation method thereof

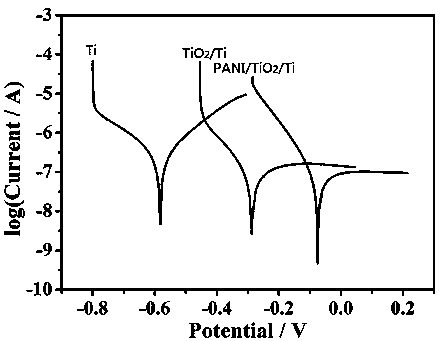

A technology of anti-corrosion coating and surface compounding, applied in surface reaction electrolytic coating, anti-corrosion coating, coating and other directions, can solve the problems of poor adhesion between coating and substrate, uneven surface coating, difficult process control, etc. Achieve the effect of improving anti-corrosion performance, reducing elastic modulus and hardness, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

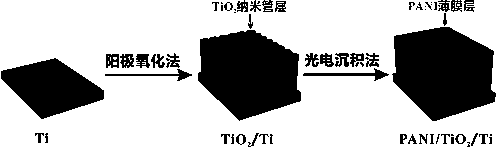

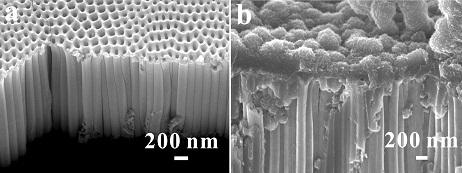

[0025] The preparation method of the composite anticorrosion coating on the surface of medical metal titanium or titanium alloy, the steps are as follows:

[0026] Step 1: Use metal titanium or titanium alloy as the positive electrode, graphite sheet as the negative electrode, and an ethylene glycol solution with a concentration of 0.1 wt% ammonium fluoride as the electrolyte. Under the action of a constant voltage of 40 V, the reaction time is 1 h. primary oxidation of the metal. The oxide layer on the surface of the metal titanium or titanium alloy after the primary oxidation is removed by ultrasonic method, and the secondary oxidation is carried out under the same conditions with a reaction time of 0.1 h to prepare a titanium dioxide nanotube layer with a regular tubular array structure. Calcining at a high temperature of 400 °C for 1.5 h transformed titanium dioxide from amorphous to anatase.

[0027] Step 2: The metal titanium or titanium alloy grown with a titanium diox...

Embodiment 2

[0029] The preparation method of the composite anticorrosion coating on the surface of medical metal titanium or titanium alloy, the steps are as follows:

[0030] Step 1: Use metal titanium or titanium alloy as the positive electrode, graphite sheet as the negative electrode, and an ethylene glycol solution with a concentration of 2 wt% ammonium fluoride as the electrolyte. Under the action of a constant voltage of 80 V, the reaction time is 30 h. primary oxidation of the metal. The oxide layer on the surface of the metal titanium or titanium alloy after the primary oxidation is removed by ultrasonic method, and the secondary oxidation is carried out under the same conditions with a reaction time of 7 h to prepare a titanium dioxide nanotube layer with a regular tubular array structure. Calcining at a high temperature of 500 °C for 3.5 h transformed the titanium dioxide from amorphous to anatase.

[0031] Step 2: The metal titanium or titanium alloy grown with a titanium dioxi...

Embodiment 3

[0033] The preparation method of the composite anticorrosion coating on the surface of medical metal titanium or titanium alloy, the steps are as follows:

[0034] Step 1: Use metal titanium or titanium alloy as the positive electrode, graphite sheet as the negative electrode, and an ethylene glycol solution with a concentration of 0.4 wt% ammonium fluoride as the electrolyte. Under the action of a constant voltage of 55 V, the reaction time is 5 h. primary oxidation of the metal. The oxide layer on the surface of the metal titanium or titanium alloy after the primary oxidation is removed by ultrasonic method, and the secondary oxidation is carried out under the same conditions with a reaction time of 0.5 h to prepare a titanium dioxide nanotube layer with a regular tubular array structure. Calcining at a high temperature of 420 °C for 2 h transformed titanium dioxide from amorphous to anatase.

[0035] Step 2: The metal titanium or titanium alloy grown with a titanium dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com