Preparation method and application of carbon paper or carbon cloth supported hetero atom-doped molybdenum carbide hydrogen evolution catalyst

A heteroatom and catalyst technology, applied in the field of catalyst materials, to achieve the effects of multiple active sites, conducive to electron transport, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

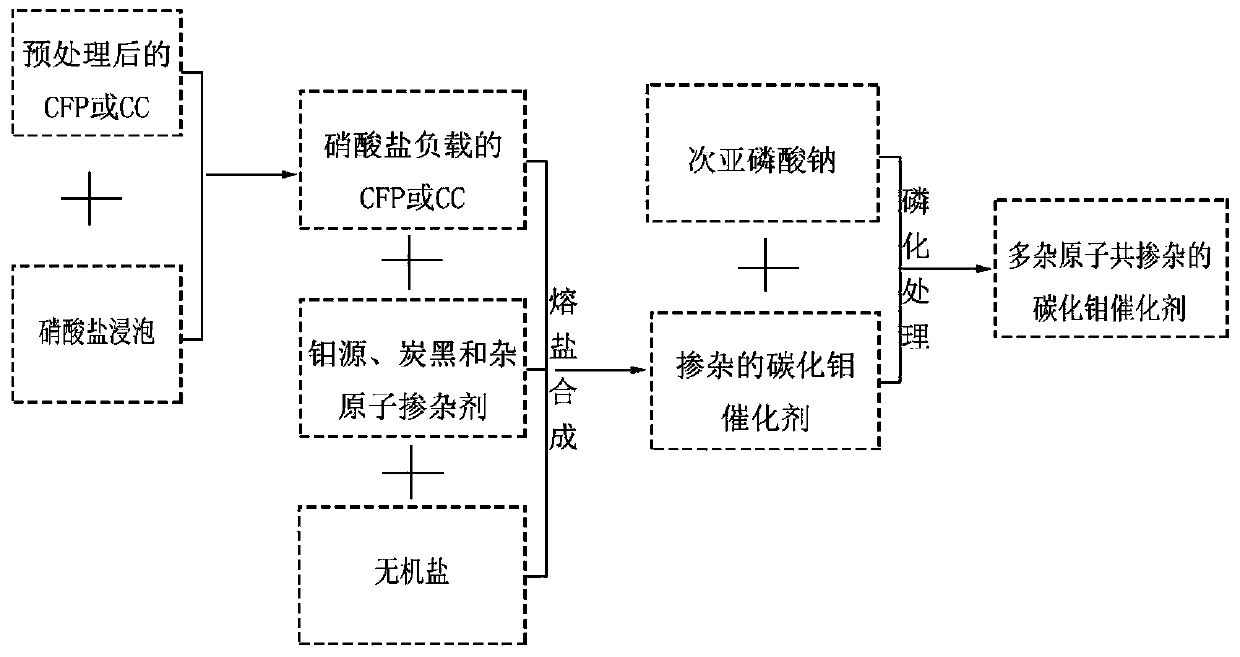

Method used

Image

Examples

preparation example Construction

[0038] The preparation method includes: first weighing the mass of carbon fiber paper or carbon fiber cloth, then using alcohol, 0.1 mol / L sulfuric acid, and distilled water to sonicate for 10 minutes respectively, and finally drying at 100° C. for 2 hours. Then, 1-25 wt% of the transition metal nitrate compound is configured into a transition metal nitrate aqueous solution with a mass fraction of 1-60 wt%. Then put the treated carbon fiber paper or carbon fiber cloth into the prepared transition metal nitrate aqueous solution, soak for 0-72h, and then dry at 80°C for 1-5h. Weigh the molybdenum source, carbon black, transition metal powder, sulfur element, nitrogen source, chloroplatinic acid and inorganic salts and mix them evenly, place the soaked carbon fiber paper or carbon fiber cloth on the bottom of the graphite crucible, and place the mixed Put the powder into the graphite crucible, put the graphite crucible into the tube furnace, under the inert gas atmosphere, adopt ...

Embodiment 1

[0041] First weigh the mass of 30wt% carbon fiber cloth, then use alcohol, 0.1mol / L sulfuric acid, and distilled water to sonicate for 10 minutes, and finally dry at 100°C for 2 hours. Weigh 40wt% molybdenum trioxide, 30wt% carbon black and inorganic salt (sodium chloride and potassium chloride in equimolar ratio) 30 times the total weight of the components and mix them uniformly.

[0042] Place the dried carbon fiber cloth on the bottom of the graphite crucible, put the mixed powder into the graphite crucible, put the graphite crucible in the tube furnace, and use the temperature programming method under the helium atmosphere, at room temperature to 600°C , the heating rate is 5°C / min, 600~1100°C, the heating rate is 5°C / min, then keep the temperature at 1100°C for 3 hours, take it out with the furnace cooling to room temperature, wash the residual molten salt with distilled water, and wash the obtained hydrogen evolution catalyst several times, Until the residual molten salt...

Embodiment 2

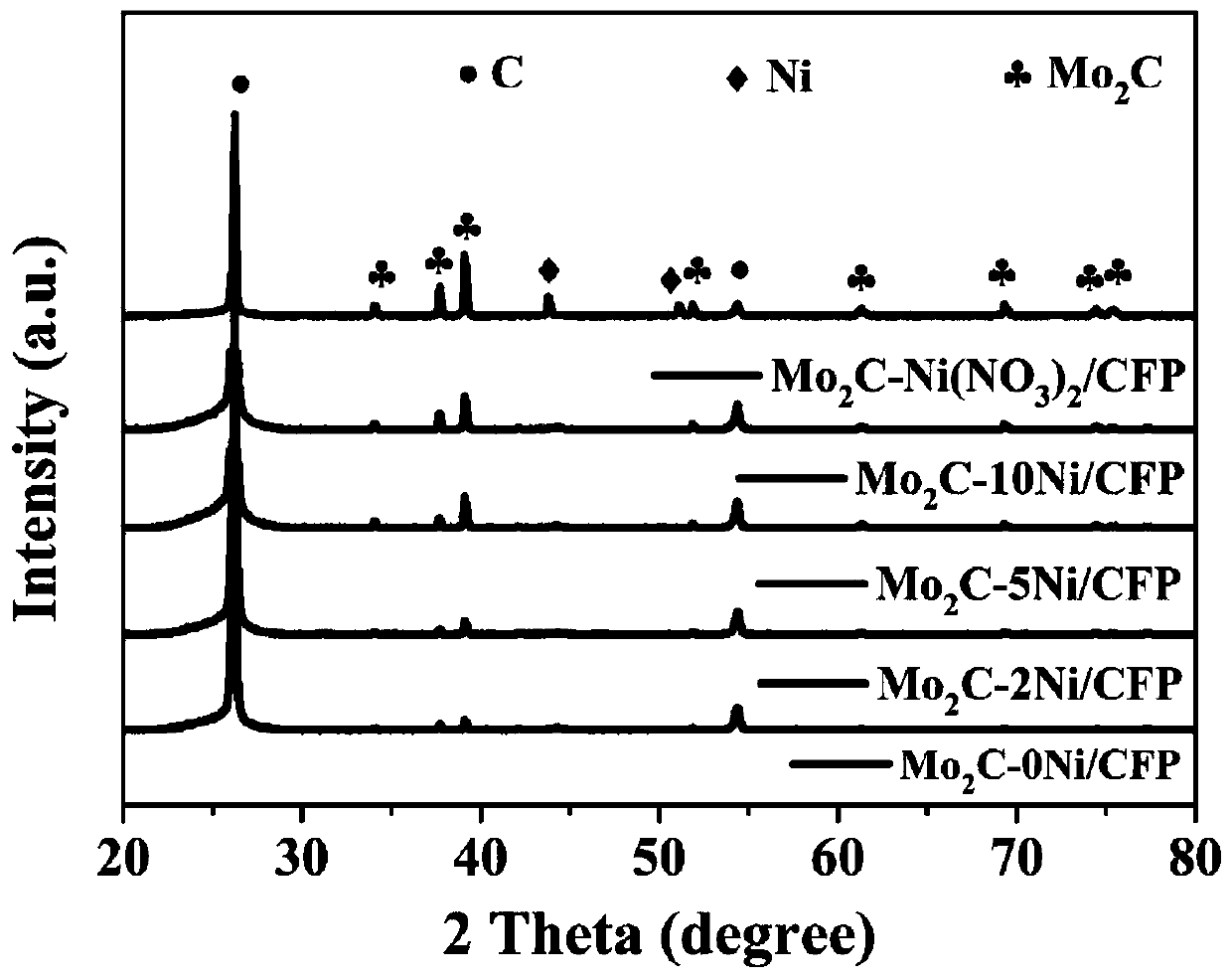

[0046] First weigh the mass of 25wt% carbon fiber paper, then use alcohol, 0.1mol / L sulfuric acid, and distilled water to sonicate for 10 minutes, and finally dry at 100°C for 2 hours. Then the 5wt% nickel nitrate compound is configured into a nickel nitrate aqueous solution with a mass fraction of 15wt%. Then put the dried carbon fiber paper into the prepared nickel nitrate aqueous solution, soak it for 5 hours, and then dry it at 80°C for 1 hour for later use.

[0047] Weigh 45wt% metal molybdenum powder, 25wt% carbon black and sodium chloride 10 times the total mass of the components and mix them evenly, place the soaked and dried carbon fiber paper on the bottom of the graphite crucible, and put the mixed powder into Put the graphite crucible into the tube furnace, under the argon atmosphere, adopt the temperature programming method, room temperature ~ 600 ℃, heating rate 10 ℃ / min, 600 ~ 800 ℃, heating rate 1 ℃ / min, Then keep it at 800°C for 10 hours, take it out with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com