A brewer's yeast strain with low-yielding higher alcohol performance and its construction method

A technology of brewer's yeast and higher alcohol, applied in the field of bioengineering, can solve the problems of unsatisfactory effect, lower content of higher alcohol, great difference in regulation effect, etc., achieve good fermentation performance and growth performance, increase content and reduce higher alcohol Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

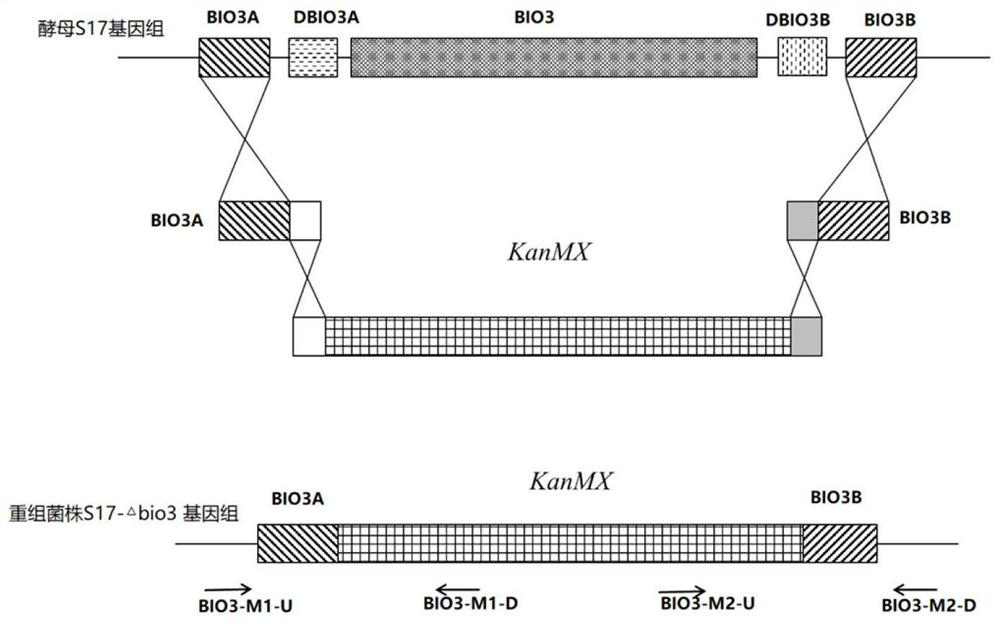

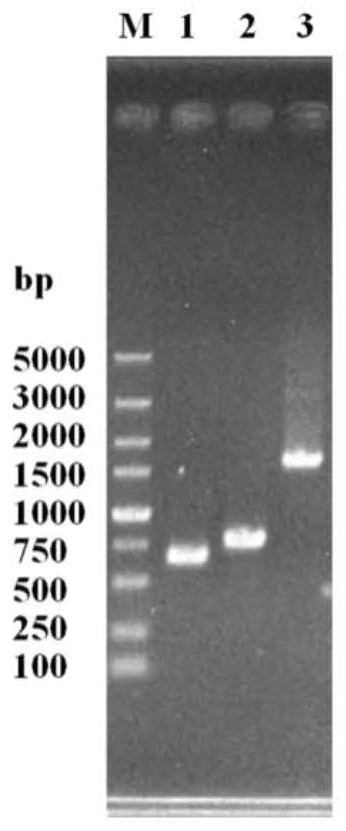

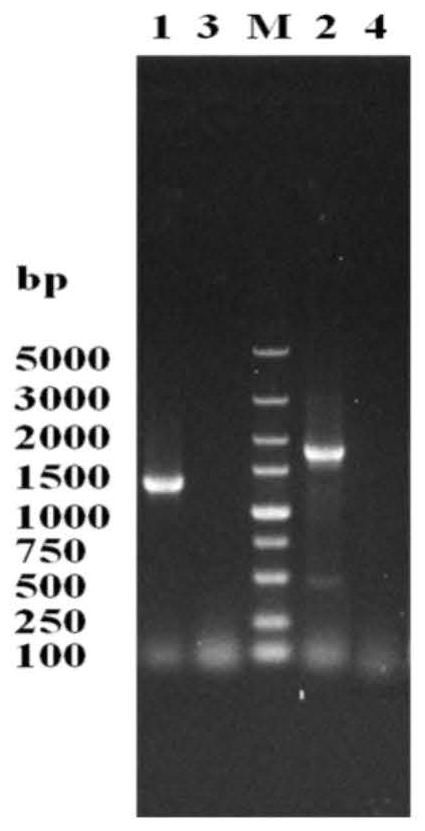

[0096] Embodiment 1: Construction of the Saccharomyces cerevisiae strain of double knockout BIO3 gene

[0097] The starting strain S. cerevisiae S17 was constructed by homologous recombination to construct recombinant genetically engineered strains.

[0098] According to the yeast genome data in Genebank and the integrated plasmid sequence, the primers in the following Example 1 were designed.

[0099] Table 1 PCR primers required for double knockout of BIO3 gene

[0100]

[0101]

[0102] The main construction process of the recombinant strain is as follows (see the attached S17-DΔbio3-k-p homologous recombination strain construction flow chart figure 1 ):

[0103] 1) Amplification of the fragment required for one allele knockout of the BIO3 gene

[0104] Using the genome of Saccharomyces cerevisiae S17 as a template, BIO3A-F and BIO3A-R were used as primer pairs to PCR amplify the upstream homologous sequence BIO3A fragment required for BIO3 gene knockout, with a le...

Embodiment 2

[0123] Embodiment 2: Construction of the Saccharomyces cerevisiae strain of double knockout BIO5 gene

[0124] The starting strain S. cerevisiae S17 was constructed by homologous recombination to construct recombinant genetically engineered strains.

[0125] According to the yeast genome data in Genebank and the integrated plasmid sequence, the primers in the following Example 2 were designed.

[0126] Table 2 PCR primers required for double knockout of BIO5 gene

[0127]

[0128]

[0129] The main construction process of the recombinant strain is as follows (see the attached S17-DΔbio5-k-p homologous recombination strain construction flow chart Figure 10 shown):

[0130] 1) Amplification of the fragment required for one allele knockout of the BIO5 gene

[0131] Using the genome of Saccharomyces cerevisiae S17 as a template, BIO5A-F and BIO5A-R were used as primer pairs to PCR amplify the upstream homologous sequence BIO5A fragment required for BIO5 gene knockout, wi...

Embodiment 3

[0150] Example 3: Fermentation experiment of recombinant strains S17-DΔbio3-k-p, S17-DΔbio5-k-p wheat beer

[0151] 1) Fermentation process roadmap (refer to attached Figure 19 shown):

[0152] 2) Process conditions: crushing conditions: the degree of crushing is suitable for wheat malt without whole grains, and the degree of crushing is not too fine, so as not to cause excessive filtration pressure; liquefaction and saccharification conditions: the crushed wheat malt is mixed with a material-to-water ratio of 1:4 Proportionally add warm water at 30°C, stir well, place in a constant temperature water bath, keep at 30°C for 30 minutes, raise the temperature to 65°C at 2.0°C / min, keep for 90 minutes, rapidly raise the temperature to 78°C, and keep for 10 minutes. Fully stir once every 5 minutes during the saccharification process; filter conditions: filter the wheat wort after saccharification while it is hot, and wash the lees with hot water at 75°C for 3 times; ‰ of bitter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com