Extraction method of succinic acid

An extraction method, the technology of succinic acid, applied in the chemical industry, can solve the problems of complex reaction conditions, electrode corrosion, high power consumption of electrolytic synthesis, etc., and achieve the effect of high extraction yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

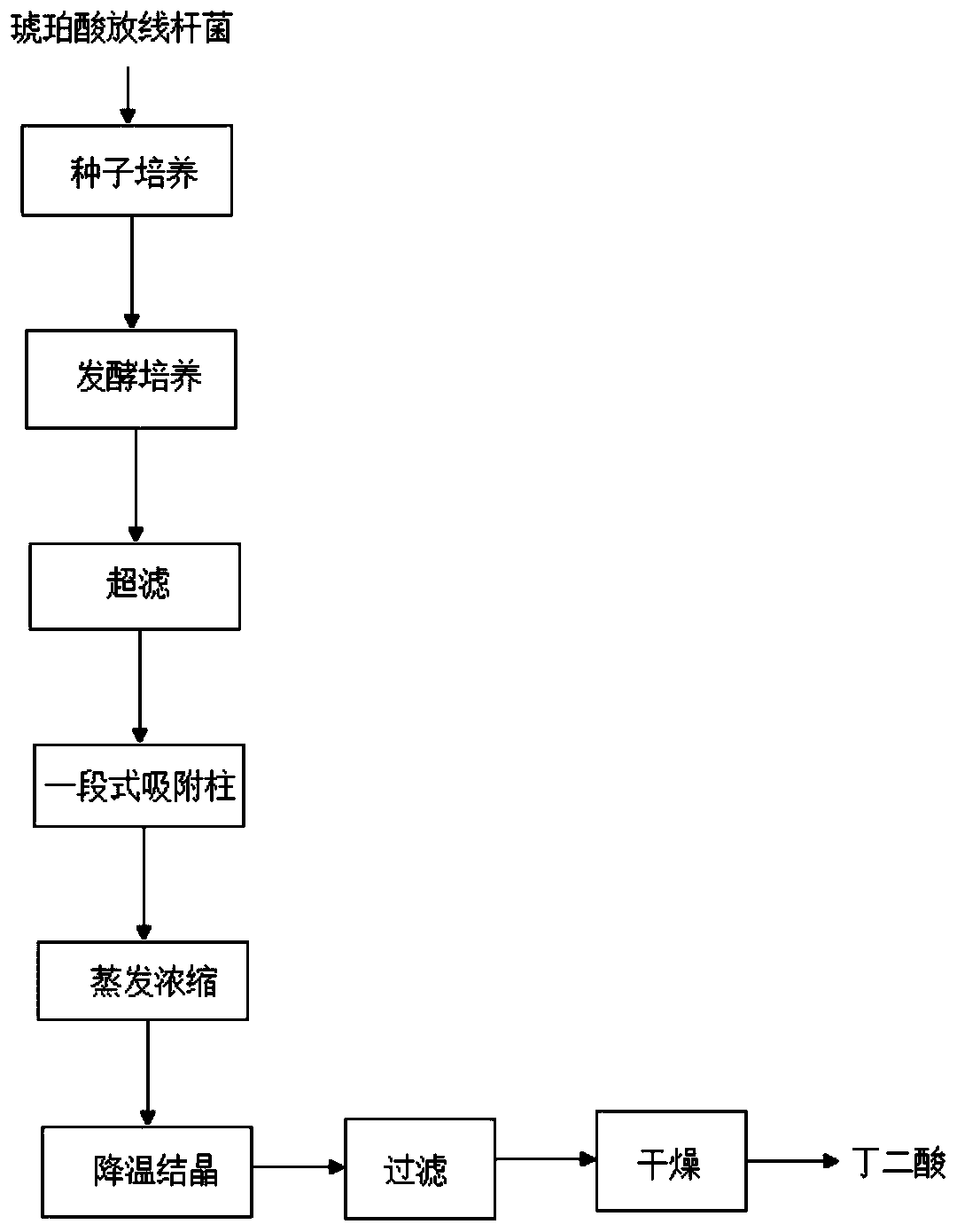

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of extraction method of succinic acid, comprises the steps:

[0034] (1) Insert Actinobacillus succinicum into the liquid seed culture medium, and culture it statically at 37°C for 14 hours, wherein, the composition of the seed culture medium, in terms of mass concentration, includes: glucose 35g / L, corn slurry 20g / L, peptone 7g / L, potassium dihydrogen phosphate 8g / L, sodium dihydrogen phosphate 12g / L, yeast extract 12g / L, deionized water;

[0035] (2) Move the actinobacillus succinic acid cultured through the seed culture medium into the fermentation medium, and obtain the succinic acid fermentation liquid through anaerobic cultivation, wherein, the composition of the fermentation medium, in terms of mass concentration, includes: Glucose 30g / L, corn steep liquor 25g / L, yeast extract 10g / L, sodium bicarbonate 3g / L, magnesium chloride 1g / L, calcium chloride 0.5g / L, basic magnesium carbonate 30g / L, deionized water, The inoculum size...

Embodiment 2

[0040] The present embodiment provides a kind of extraction method of succinic acid, comprises the steps:

[0041] (1) Insert Actinobacillus succinicum into the liquid seed culture medium and culture it statically at 37°C for 16 hours, wherein the components of the seed culture medium include: glucose 30g / L, corn slurry 20g / L, peptone 7g / L, potassium dihydrogen phosphate 6g / L, sodium dihydrogen phosphate 10g / L, yeast extract 10g / L, deionized water;

[0042] (2) Move the actinobacillus succinic acid cultured through the seed culture medium into the fermentation medium, and obtain the succinic acid fermentation liquid through anaerobic cultivation, wherein, the composition of the fermentation medium, in terms of mass concentration, includes: Glucose 35g / L, corn steep liquor 20g / L, yeast extract 12g / L, sodium bicarbonate 3.5g / L, magnesium chloride 1g / L, calcium chloride 0.6g / L, basic magnesium carbonate 25g / L, deionized water , the inoculum size of Actinobacillus succinate is 10...

Embodiment 3

[0047] The present embodiment provides a kind of extraction method of succinic acid, comprises the steps:

[0048] (1) Insert Actinobacillus succinicum into the liquid seed culture medium and culture it statically at 37°C for 12 hours, wherein the composition of the seed culture medium includes: glucose 32g / L, corn slurry 25g / L, peptone 6g / L, potassium dihydrogen phosphate 8g / L, sodium dihydrogen phosphate 10g / L, yeast extract 10g / L, deionized water;

[0049] (2) Move the actinobacillus succinic acid cultured through the seed culture medium into the fermentation medium, and obtain the succinic acid fermentation liquid through anaerobic cultivation, wherein, the composition of the fermentation medium, in terms of mass concentration, includes: Glucose 30g / L, corn steep liquor 15g / L, yeast extract 10g / L, sodium bicarbonate 2g / L, magnesium chloride 1g / L, calcium chloride 0.3g / L, basic magnesium carbonate 25g / L, deionized water, The inoculum size of Actinobacillus succinate was 5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com