Preparation method of phosphate-coated metal-doped ternary cathode active material and preparation and application thereof

A positive electrode active material and positive electrode material technology, applied in the field of lithium ion battery positive electrode, can solve the problems of electrical performance to be further improved, no electrochemical activity, high surface alkalinity of materials, etc., to reduce ion surface diffusion and internal transfer impedance, Easy to industrialized production, reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (a) 2g nano-alumina (D50 particle size is 50nm) and 98g LiNi 0.87 co 0.03 mn 0.10 o 2 The ternary cathode material (D50 particle size 9 μm) is dispersed in a mixed solution of 120ml ethanol and water (the volume ratio of ethanol to aqueous solution is 7:3), after ultrasonic treatment and evaporation to dryness, heat to 450°C and keep it warm for 2.5h to obtain nano-oxidation Aluminum clad LiNi 0.87 co 0.03 mn 0.10 o 2 Ternary cathode material.

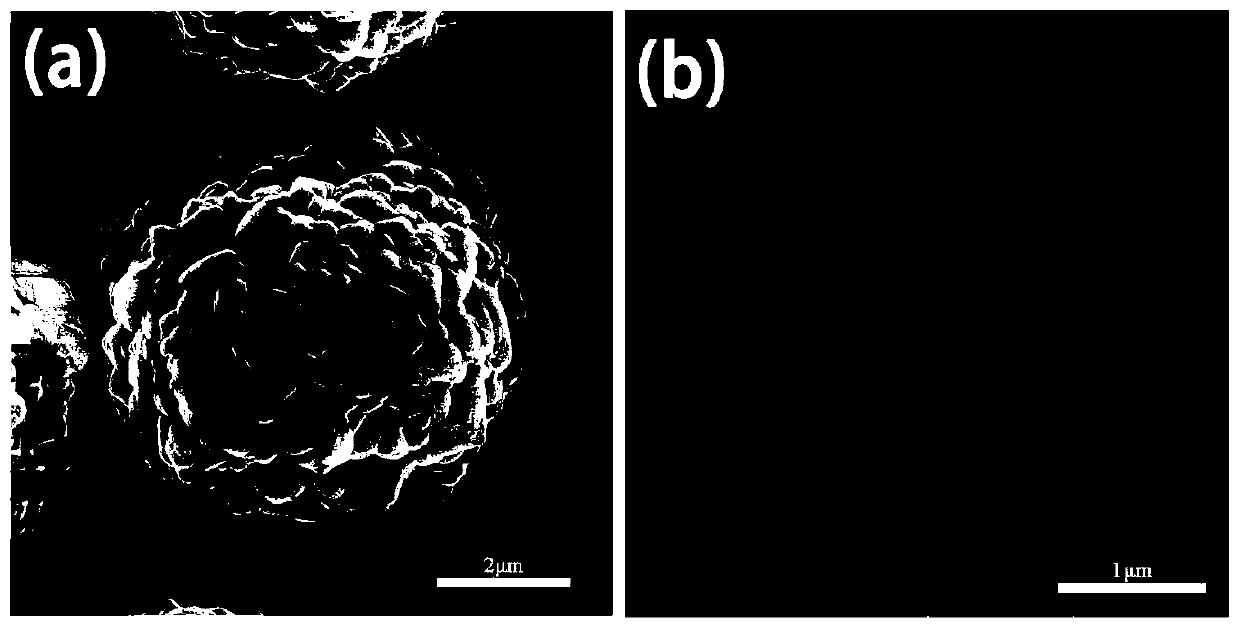

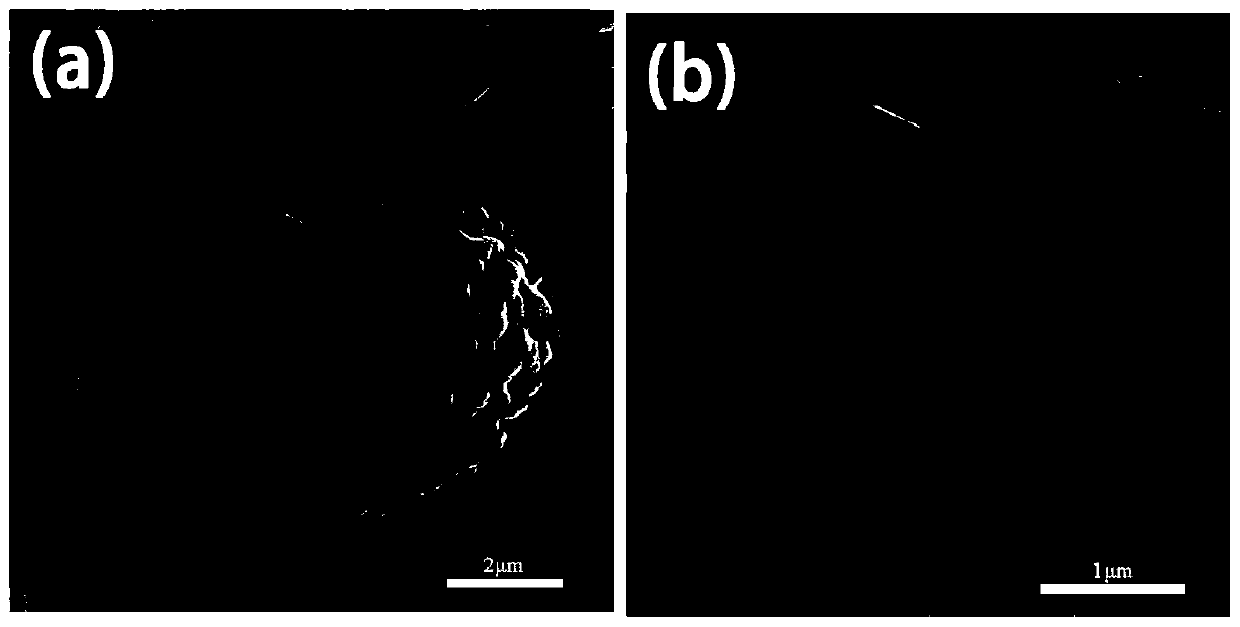

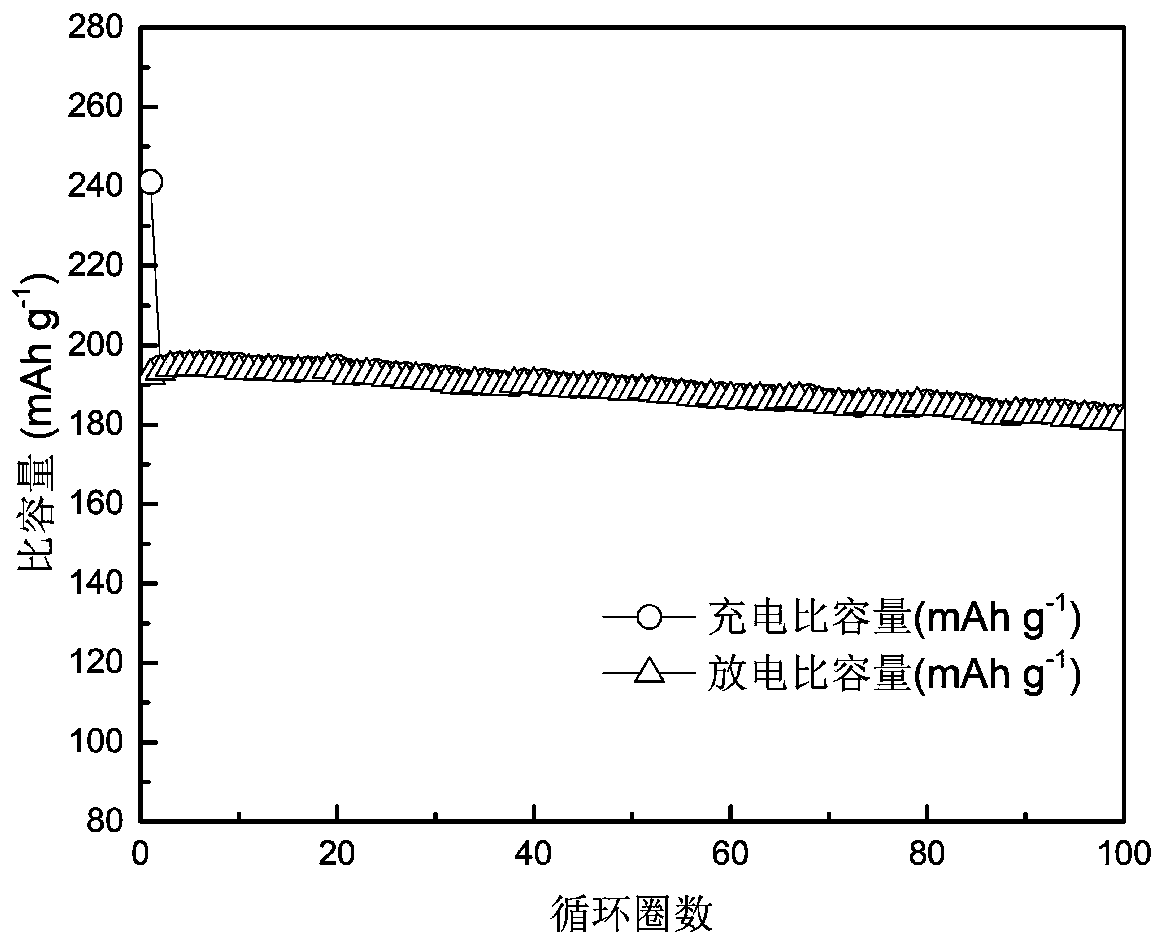

[0059] (b) After ammonium phosphate coarse particles are ground into powder, sieve to obtain D50 particle diameter and be the ammonium phosphate of 8 microns, 3.5g ammonium phosphate (with the mol ratio of nano-alumina is 1.2:1) and step (a) obtain Nano-alumina coated LiNi 0.87 co 0.03 mn 0.10 o 2 After mixing the ternary cathode materials evenly, heat them to 600°C and keep them warm for 2.5h to obtain AlPO 4 Coating, Al 3+ Element-doped LiNi 0.87 co 0.03 mn 0.10 o 2 Ternary cathode material. SEM of materials ...

Embodiment 2

[0066] (a) 3g nano-cerium oxide (D50 particle size 60nm) and 97g LiNi 0.8 co 0.1 mn 0.1 o 2 The ternary positive electrode material (D50 particle size 8 μm) is dispersed in a mixed solution of 150ml ethanol and water (the volume ratio of ethanol and aqueous solution is 8:2), after ultrasonic treatment and evaporation to dryness, heat to 350°C and keep it for 3 hours to obtain nano-cerium oxide Coated LiNi 0.8 co 0.1 mn 0.1 o 2 Ternary cathode material.

[0067] (b) sieve the diammonium hydrogen phosphate coarse particle into powder and obtain the D50 particle diameter as the diammonium hydrogen phosphate of 8 microns, 3g diammonium hydrogen phosphate (with the mol ratio of nano cerium oxide being 1.3:1) and step (a) The obtained nano-ceria coated LiNi 0.8 co 0.1 mn 0.1 o 2 After the ternary cathode material, it was heated to 600°C and kept for 2.5h to obtain CePO 4 Coating, Ce 3+ Element-doped LiNi 0.8 co 0.1 mn 0.1 o 2 Ternary cathode material.

Embodiment 3

[0088] (a) 4g nano strontium oxide (D50 particle size 80nm) and 96g LiNi 0.83 co 0.7 mn 0.10 o 2 The ternary cathode material (D50 particle size 9 μm) was dispersed in a mixed solution of 135ml ethanol and water (the volume ratio of ethanol and aqueous solution was 7:3), after ultrasonic treatment and evaporation to dryness, heated to 380°C and kept for 3 hours to obtain nano-strontium oxide Coated LiNi 0.83 co 0.7 mn 0.10 o 2 Ternary cathode material.

[0089] (b) After grinding the ammonium dihydrogen phosphate coarse particles into powder, sieve to obtain the ammonium dihydrogen phosphate with a D50 particle size of 7 microns, 5.6g diammonium hydrogen phosphate (with the mol ratio of nanometer strontium oxide being 1.25:1) and The LiNi coated with nanometer strontium oxide that step (a) obtains 0.83 co 0.7 mn 0.10 o 2 After the ternary cathode material, it was heated to 600°C and kept for 2.5h to obtain SrHPO 4 Coating, Sr 2+ Element-doped LiNi 0.83 co 0.7 mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com