Method for preparing high-density crown ether site porous adsorbent by surface photoinitiation

A porous adsorbent, high-density technology, applied in chemical instruments and methods, process efficiency improvement, alkali metal oxides/hydroxides, etc. It can improve the kinetic performance, avoid binding instability, and simplify the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

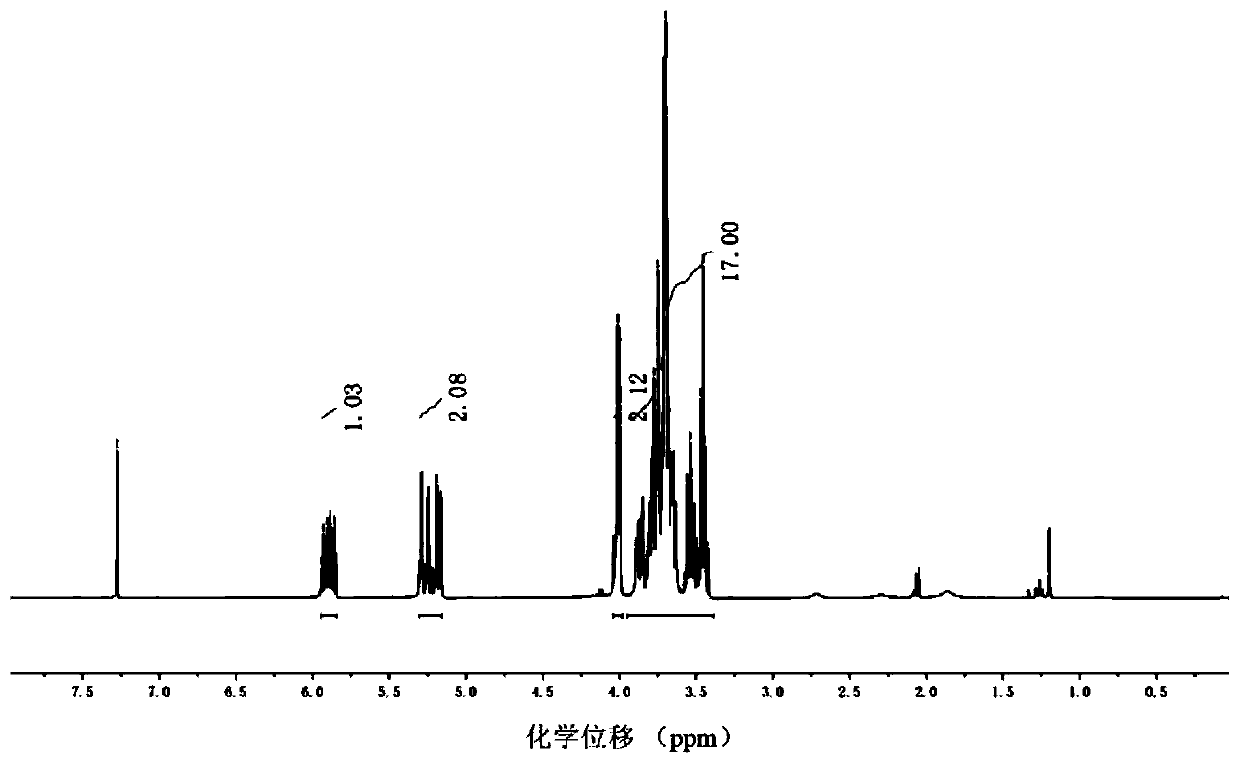

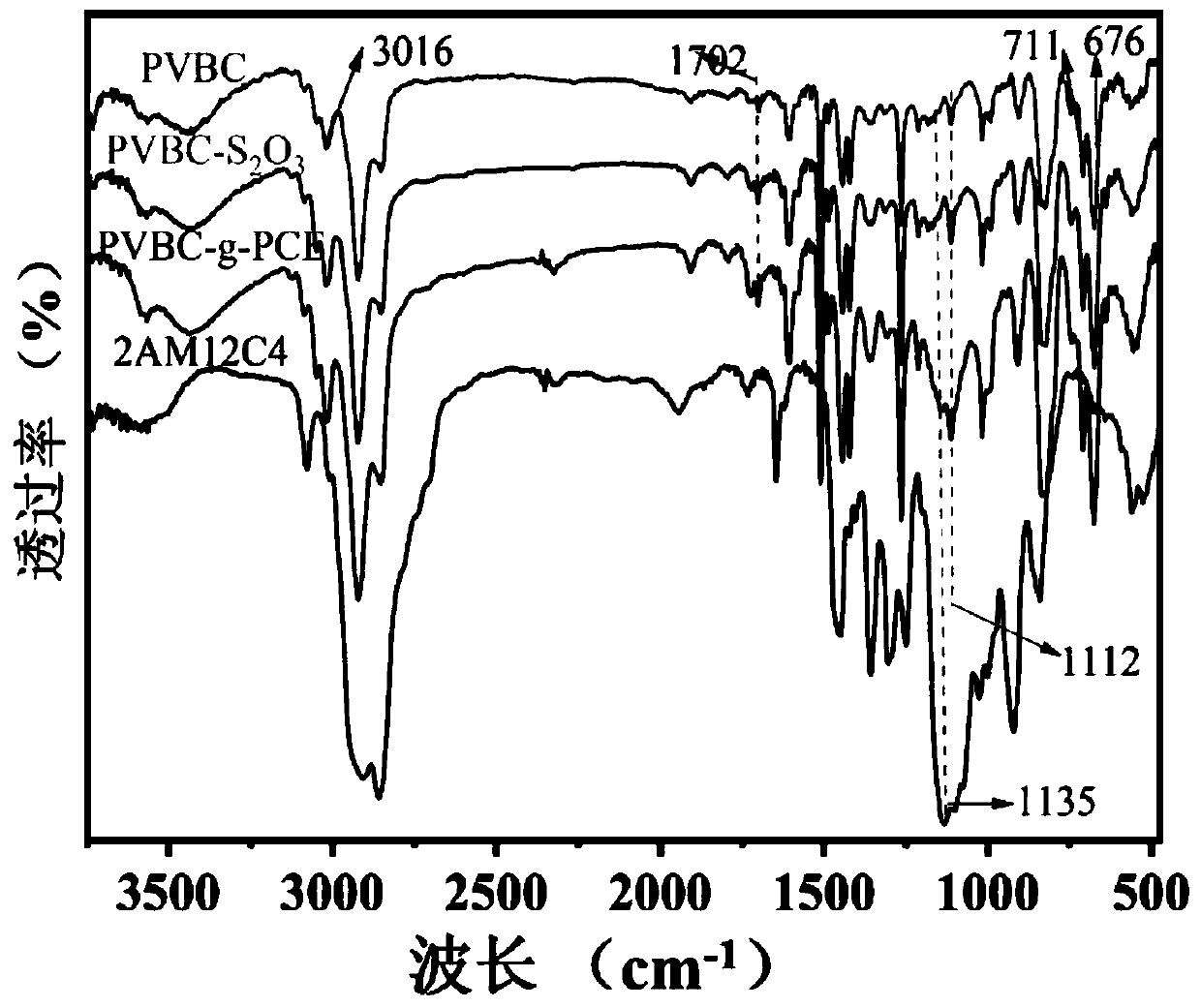

[0041] (1) Preparation of 2AM12C4;

[0042] Mix 9mmol of 30% potassium hydride dispersion in mineral oil with 1.9mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 30mL DMF for 30min at room temperature, then add 10mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane with a volume ratio of 1:2: EtOAc to obtain 2AM12C4;

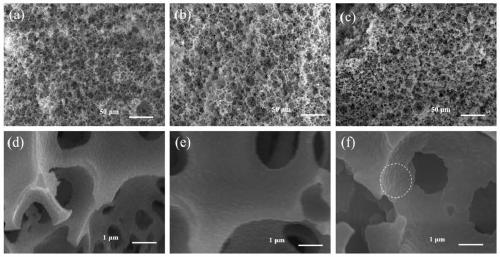

[0043] (2) Preparation of porous polymer (PVBC) with chloromethyl groups on the surface;

[0044] Add 3.0mL 4-VBC, 0.5mL EGDMA, and 30mg AIBN into a 100mL three-neck flask, and sonicate for 5.0min to completely dissolve AIBN. Under mechanical stirring at 500rpm, slowly add 1.0mL Hypermer 2296 dropw...

Embodiment 2

[0055] (1) Preparation of 2AM12C4;

[0056] Mix 12 mmol of 30% potassium hydride dispersion in mineral oil with 2.2 mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 40 mL of DMF for 30 min at room temperature, then add 12 mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane:EtOAc with a volume ratio of 1:2 to obtain 2AM12C4;

[0057] (2) preparation of porous polymer (PVBC);

[0058] Add 4.0mL of 4-VBC, 0.67mL of EGDMA, and 40mg of AIBN into a 100mL three-neck flask, and sonicate for 8.0min to completely dissolve AIBN. Under mechanical stirring at 700rpm, slowly add 1.34mL Hypermer 2296 dropwise to the flask, aft...

Embodiment 3

[0064] (1) Preparation of 2AM12C4;

[0065] Mix 15 mmol of 30% potassium hydride dispersion in mineral oil with 2.5 mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 50 mL of DMF for 30 min at room temperature, then add 15 mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane:EtOAc with a volume ratio of 1:2 to obtain 2AM12C4;

[0066] (2) preparation of porous polymer (PVBC);

[0067] Add 5.0mL 4-VBC, 0.83mL EGDMA, and 50mg AIBN into a 100mL three-necked flask, and sonicate for 10.0min to completely dissolve AIBN. Under mechanical stirring at 1000rpm, slowly add 1.67mL Hypermer 2296 dropwise to the flask, after mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com